Method for preparing surfactants for displacement of oil

A surfactant and oil displacement technology, applied in chemical instruments and methods, drilling compositions, dissolution, etc., can solve the problems of difficult control of sulfonation reaction process speed, uneven mixing, etc., achieve good interfacial activity, improve reaction , The effect of short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Alkylbenzene between C9-C22 and fuming sulfuric acid with a concentration of 20% (wt) are put into a high-gravity rotating bed reactor with a processing capacity of 3L at a mass ratio of 0.3:1, and the speed of the high-gravity machine is 700 rev / min, the rotating speed of the stirring paddle is 800 rev / min, the sulfonation temperature is 30°C, the sulfonation reaction is an instantaneous continuous reaction, and the sulfonation reaction time is 5s.

[0021] Acid separation: add 5% (wt) of water in the total amount to the mixture of alkylbenzenesulfonic acid and sulfuric acid, the temperature of acid separation is 60°C, the time of acid separation is 1h, and the upper layer of alkylbenzenesulfonic acid is separated.

[0022] Neutralization: NaOH with a concentration of 25% (wt) neutralizes the separated alkylbenzenesulfonic acid to a pH value of 8-9.

[0023] Compounding: Add 5% (wt) isopropanol to the product at 20°C.

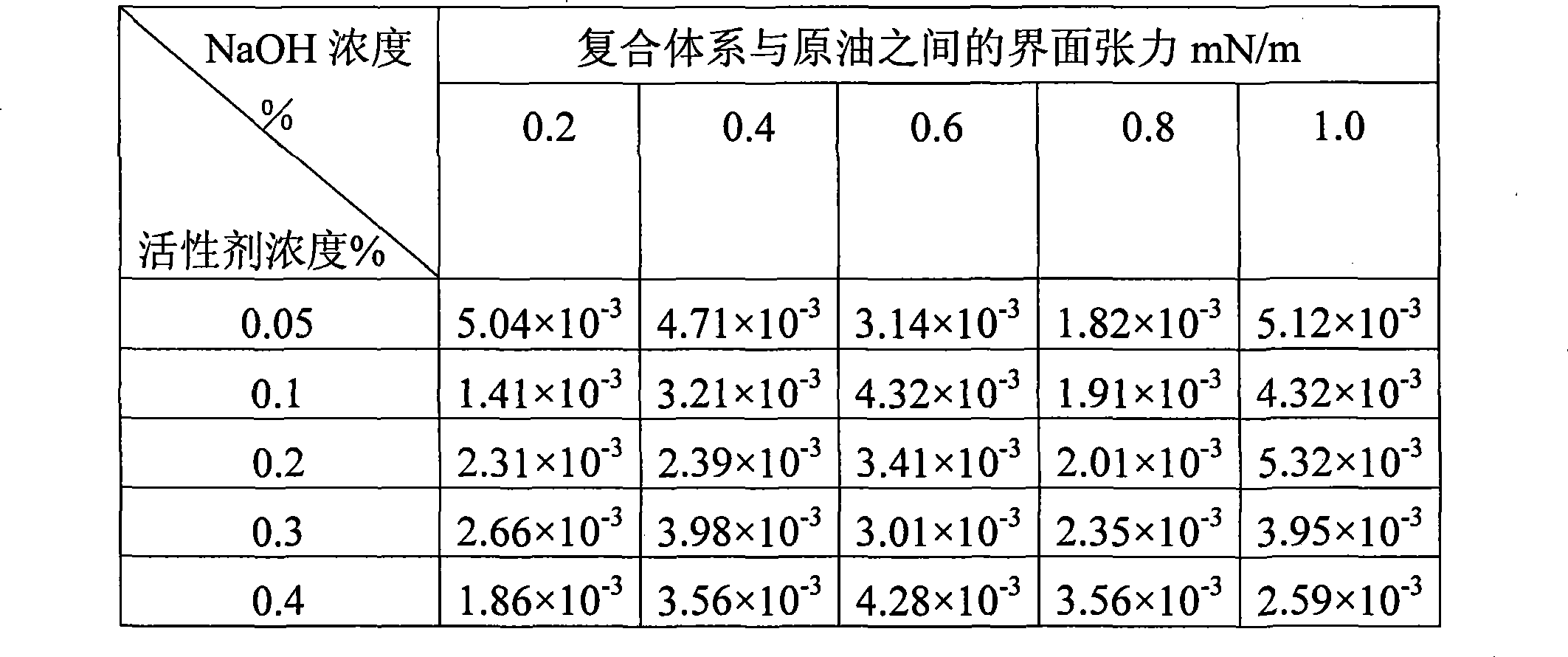

[0024] Using the prepared alkylbenzene sulfonate...

Embodiment 2

[0028] Alkylbenzene between C9-C22 and oleum with a concentration of 50% are injected into a high-gravity rotating bed reactor with a processing capacity of 3L at a mass ratio of 0.5:1, and the speed of the high-gravity machine is 2000 rpm , the sulfonation temperature is 50°C, the sulfonation reaction is an instantaneous continuous reaction, and the sulfonation reaction time is 10s.

[0029] Acid separation: add 10% (wt) water in total to the mixture of alkylbenzenesulfonic acid and sulfuric acid, the temperature of acid separation is 70°C, the time of acid separation is 2h, and the upper layer of alkylbenzenesulfonic acid is separated.

[0030] Neutralization: NaCO with a concentration of 25% (wt) 3 Neutralize the separated alkylbenzenesulfonic acid to pH 8-9.

[0031] Compounding: at 20° C., add 15% (wt) n-butanol to the product.

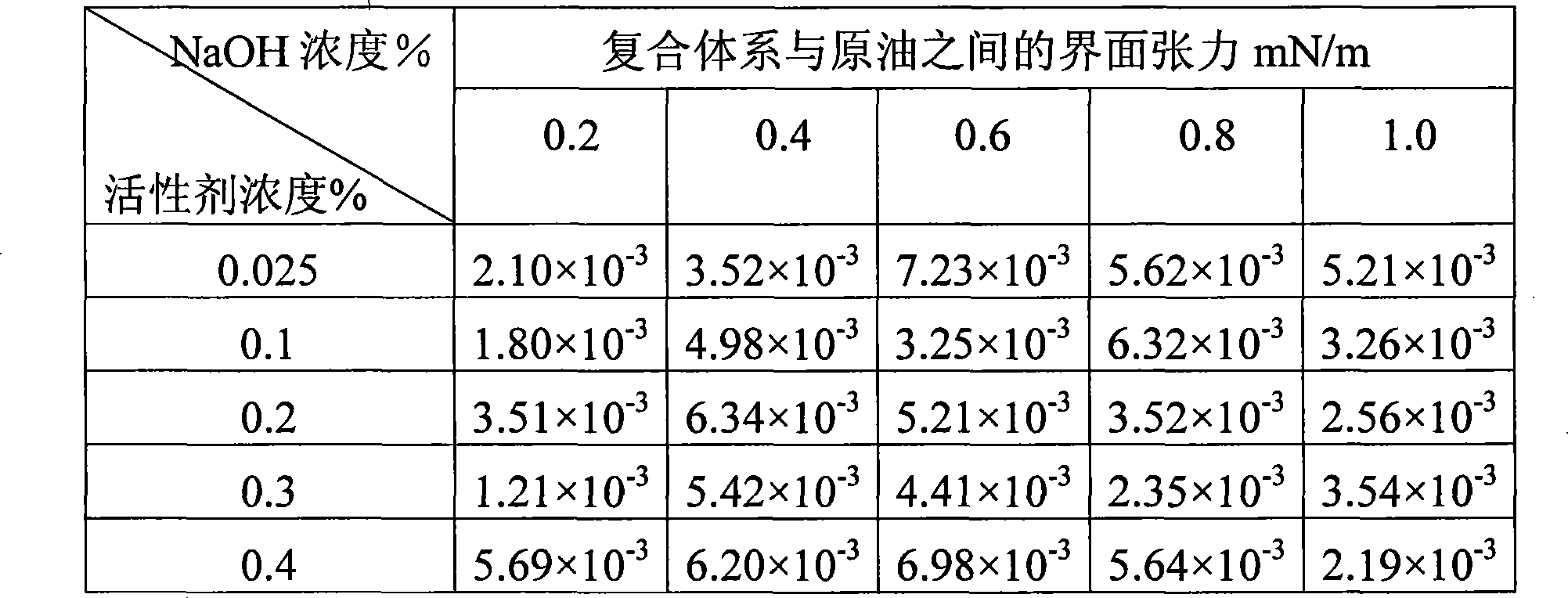

[0032] Others are the same as in Example 1, and the test results are shown in Table 2.

[0033] Table 2 Interfacial tension between weak base...

Embodiment 3

[0036] Alkylbenzene between C9-C22 and oleum with a concentration of 20% are injected into a high-gravity rotating bed reactor with a processing capacity of 3L at a mass ratio of 0.8:1, and the speed of the high-gravity machine is 200 rpm , the sulfonation temperature is 60°C, the sulfonation reaction is an instantaneous continuous reaction, and the sulfonation reaction time is 15s.

[0037] Acid separation: add 20% (wt) of water to the mixture of alkylbenzenesulfonic acid and sulfuric acid, the temperature of acid separation is 70°C, the time of acid separation is 3h, and the upper layer of alkylbenzenesulfonic acid is separated.

[0038] Compounding: at 20° C., add 10% (wt) n-butanol to the product.

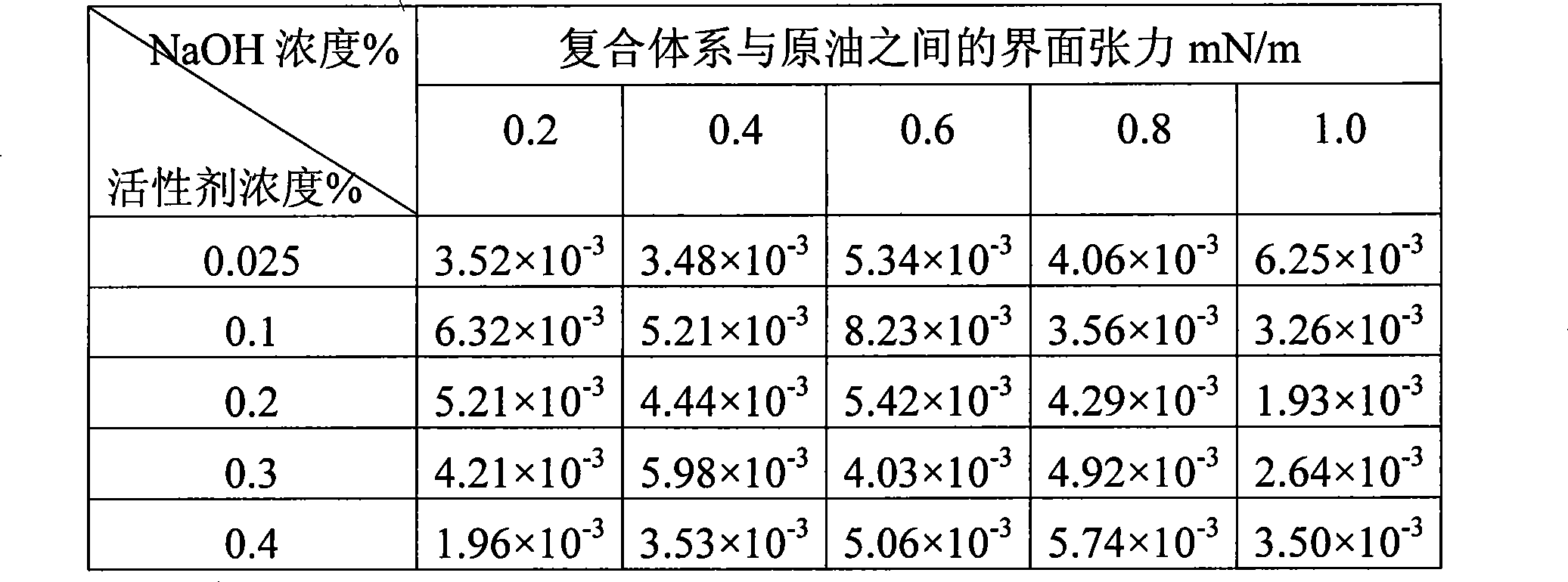

[0039] Others are the same as in Example 1, and the test results are shown in Table 3.

[0040] Table 3 Interfacial tension between weak base alkylbenzene sulfonate surfactant / alkali system and crude oil

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com