Crystal silicon ingot furnace thermal field thermal gate control device and control method thereof

A control device and an ingot furnace technology, which are applied in the field of ingot casting in a crystalline silicon ingot furnace, can solve the problems of uneven symmetry of heat dissipation channels, influence on nucleation quality, crystal nucleation and growth influence, etc., so as to make full use of heat dissipation area , to meet the process requirements, the effect of good control ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

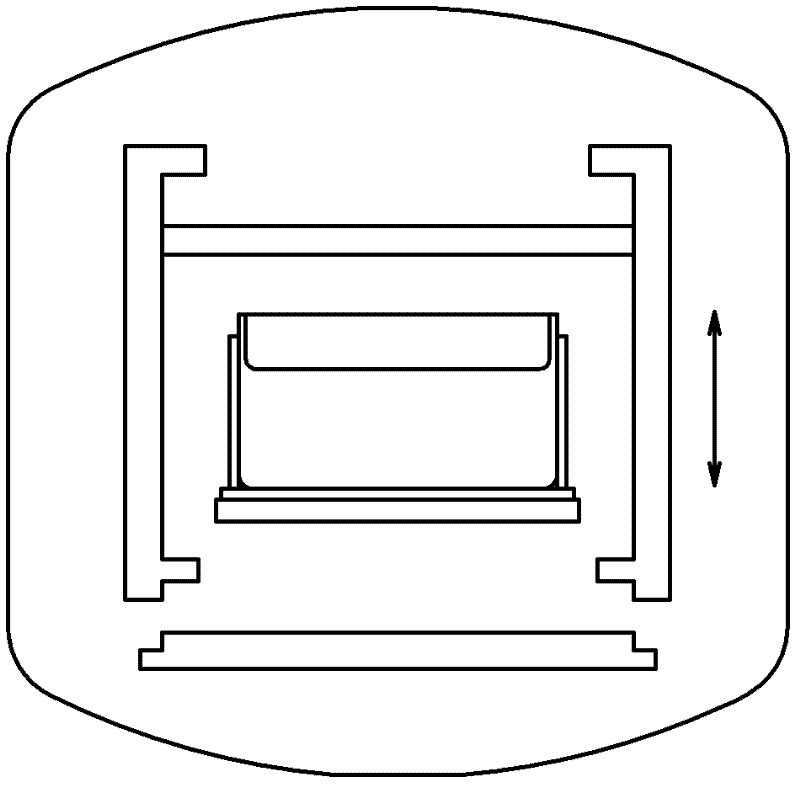

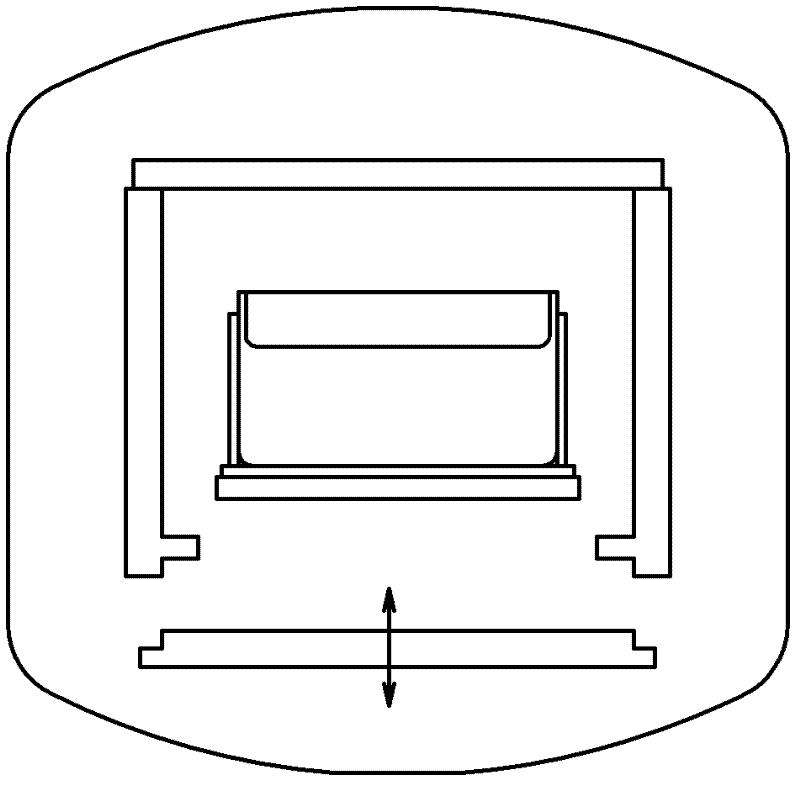

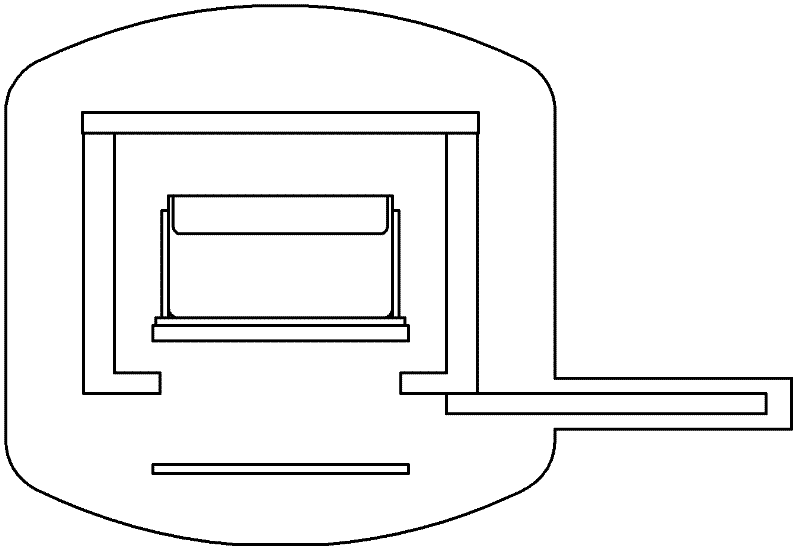

[0043] like Figure 5-11 In the hot field control device shown in the figure, a crucible 2 and a heat exchange table 3 for containing crystalline silicon raw materials are arranged in the heat insulation cage 1, and a cold plate 4 through which cooling water is passed through the inside of the heat insulation cage 1 is arranged below the heat insulation cage 1. A heat shield assembly is arranged between the bottoms of the cage, and the opening formed in the center of the heat shield assembly can be gradually opened to the surroundings or closed to the center in a centrally symmetrical manner.

[0044]The heat shield assembly is composed of four fan-shaped circular heat shields 5 evenly distributed in the circumferential direction. There is an arc-shaped receiving opening on the bottom of one side of the heat shield, and an arc-shaped lap joint on the other side surface. platform; the arc-shaped receiving opening of a heat shield is used to accommodate the arc-shaped overlappin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com