Fluid pump

A fluid pump and liquid pump technology, applied in the medical field, can solve the problems of high cost, unfavorable memory characteristics and normal functioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

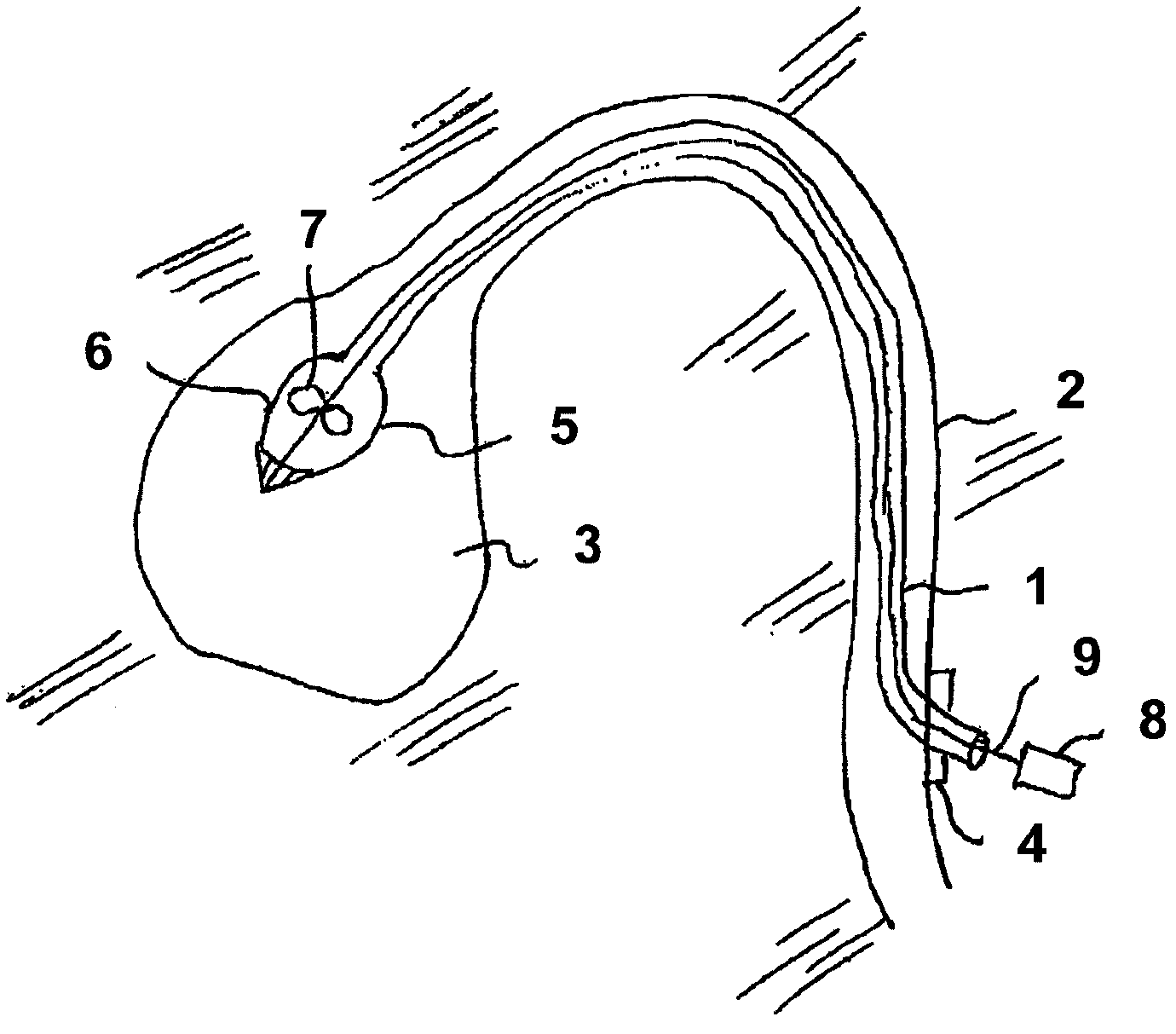

[0053] figure 1 It is shown that the catheter 1 is fed into the human blood vessel 2 directly to the ventricle 3, and passes through the blood vessel 4 through the lock 4. A catheter with a micropump 5 is guided through the lock into the ventricle 3 . To this end, when inserted, the pump is set in a retracted state, at which time the diameter of the pump casing 6 and the rotating element 7 is reduced in size. The design of this rotating element and pump housing does not present excessive restoring forces, which tend to resist the forces of the vessel wall to deploy the pump.

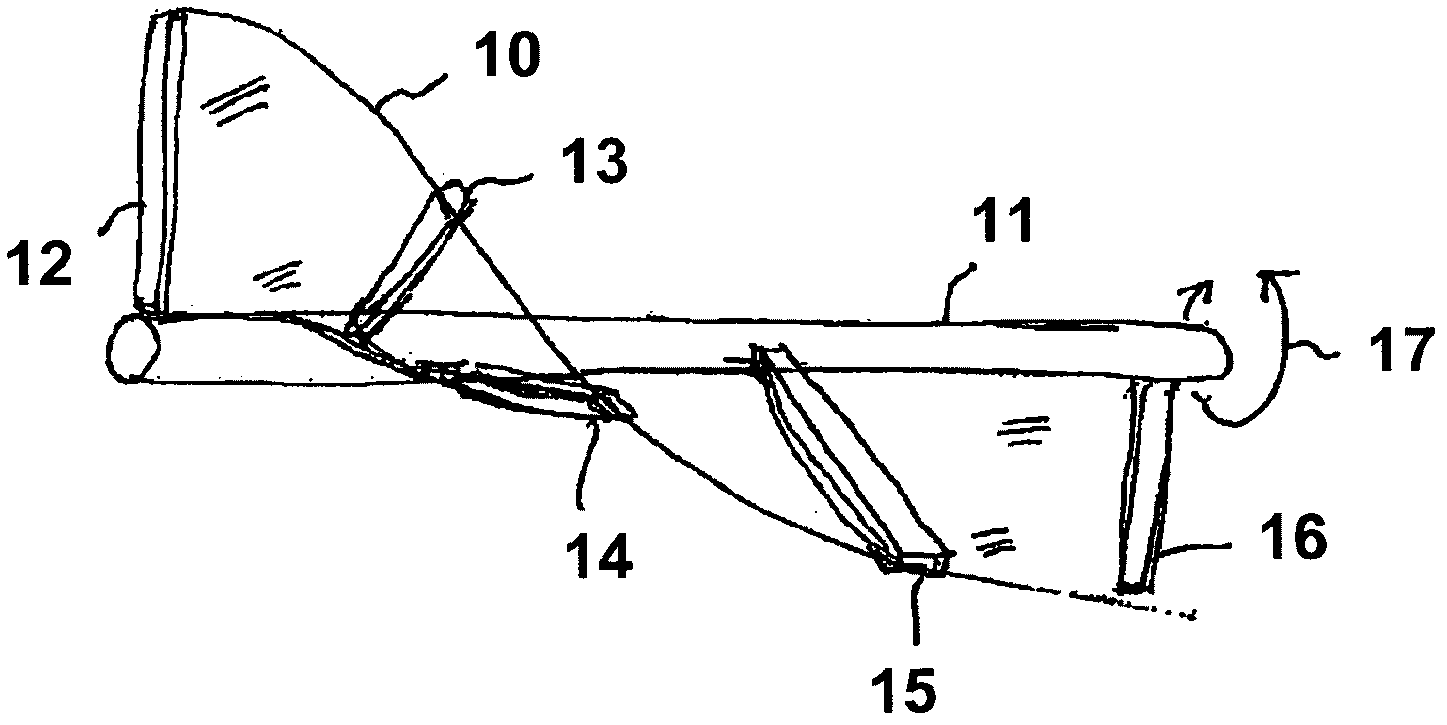

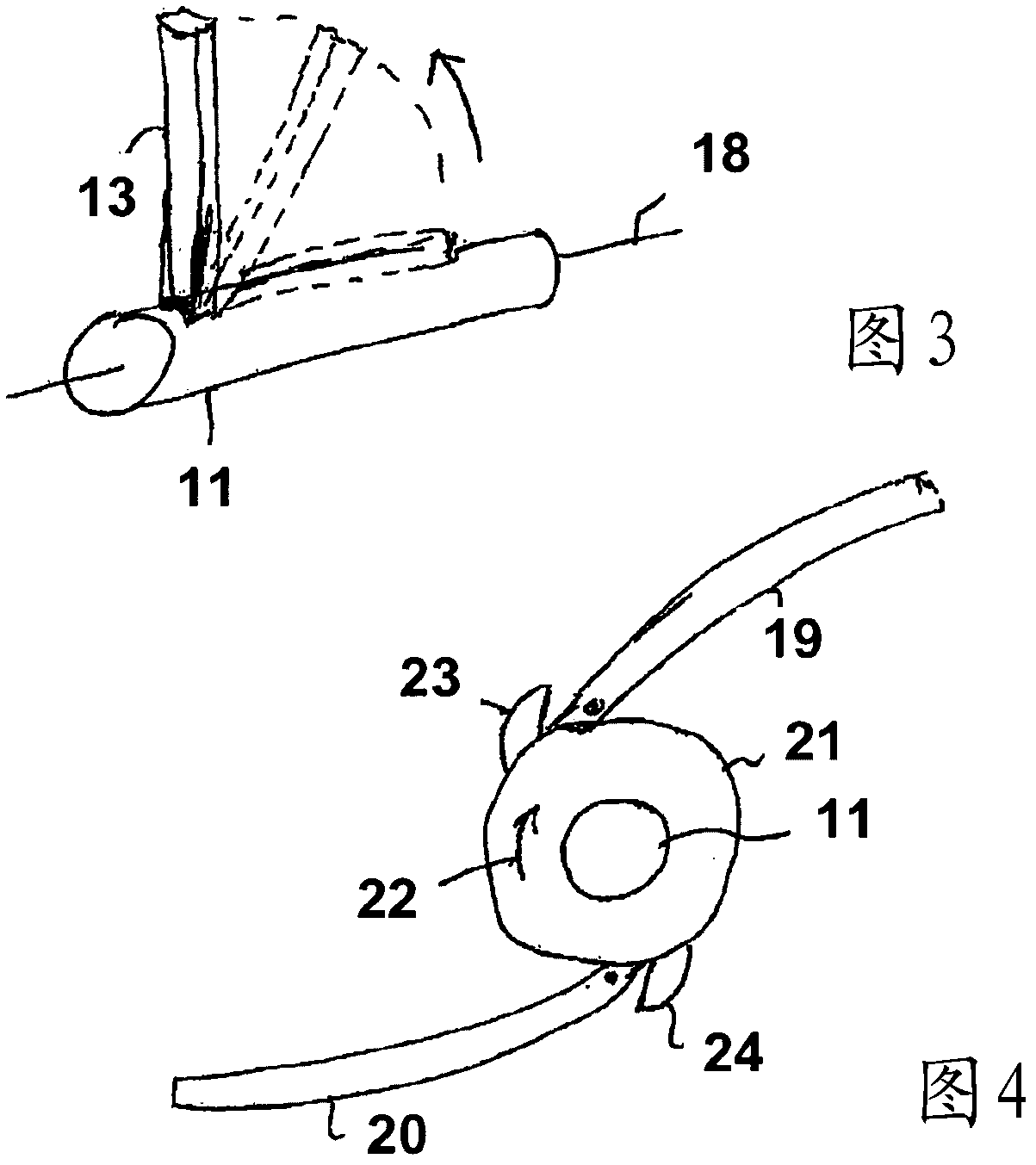

[0054] When the pump 5 has just been fed into the ventricle 3, the rotating element 7 can be rotated by means of the shaft 9 introduced through the catheter 1 in order to deliver the liquid. At the same time, if figure 2 It is shown that at least one rotating element vane is unfolded and erected by means of mechanical excitation or its own rotation, and by the action of the liquid back pressure when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com