Graphite boat (frame) dry-type cleaning machine

A dry cleaning machine, graphite boat technology, applied in cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of mechanical damage, time-consuming, low cleaning efficiency, etc., and achieve high cleaning efficiency, convenient operation, and cleaning effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

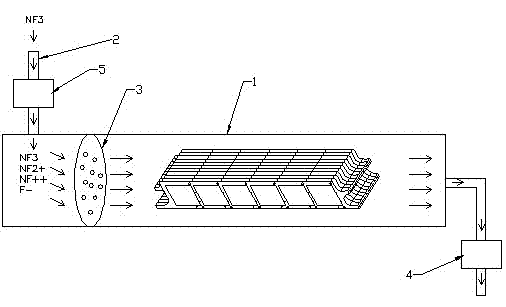

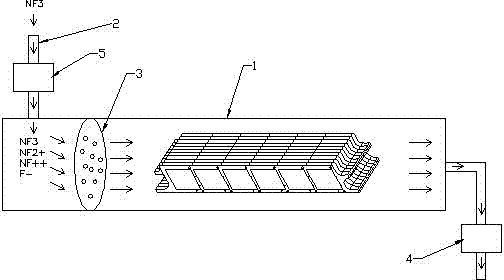

[0010] figure 1 In the illustrated embodiment, the graphite boat (frame) dry cleaning machine includes a reaction chamber 1 in which a graphite boat or a graphite frame can be placed. The inlet of the reaction chamber is connected to the NF3 gas source through an air inlet pipe 2, and the inlet of the reaction chamber is An even flow plate 3 is also provided, and the outlet of the reaction chamber is connected to the dry vacuum pump 4 through an exhaust pipe; a plasma generator 5 is installed on the intake pipe.

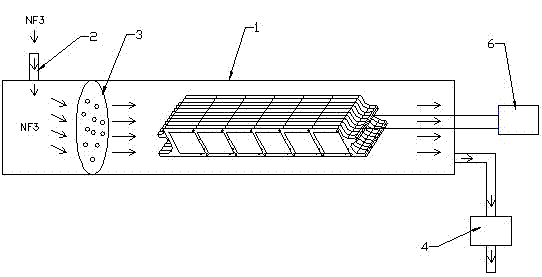

[0011] figure 2 In the illustrated embodiment, the graphite boat (frame) dry cleaning machine includes a reaction chamber 1 in which a graphite boat or a graphite frame can be placed. The inlet of the reaction chamber is connected to the NF3 gas source through an air inlet pipe 2. The reaction chamber inlet The outlet of the reaction chamber is connected to the dry vacuum pump 4 through an exhaust pipe; a radio frequency generator 6 is arranged outside the reaction cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com