Method for preparing metal nanomaterial with simulated cell structure

A technology of metal nano and metal nano particles, which is applied in the field of metal nano material preparation, can solve the problems of inability to synthesize nanostructures, damage of nano-metal core morphology, and inability to form cell-like nanostructures. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

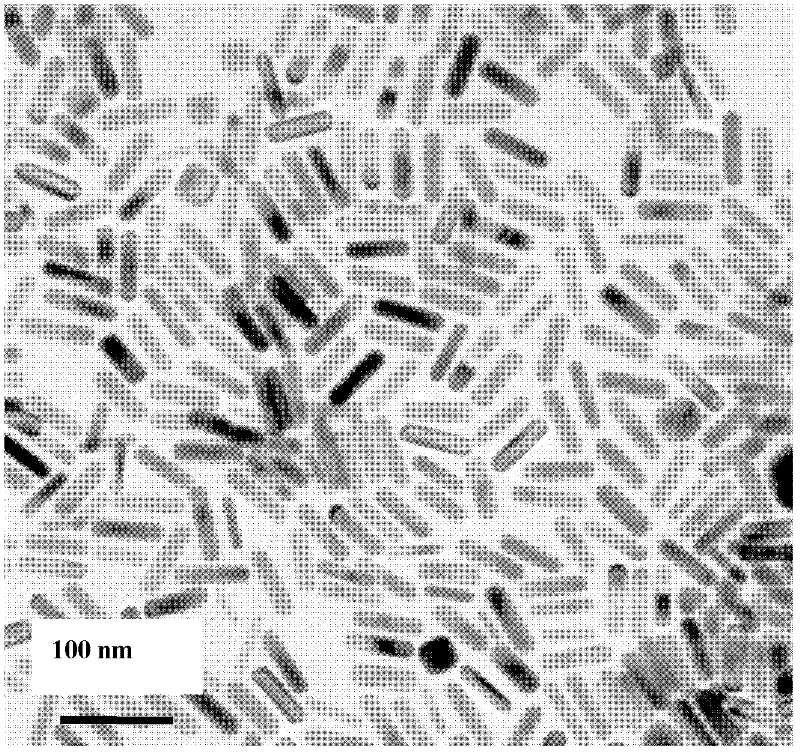

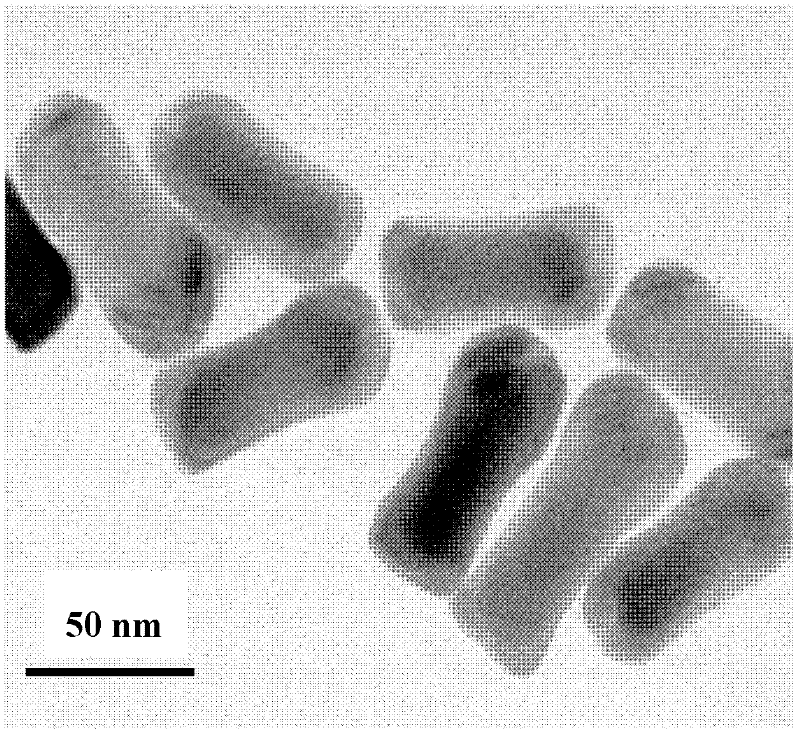

[0019] Example 1: Synthesis of nano-gold rods imitating cell structure

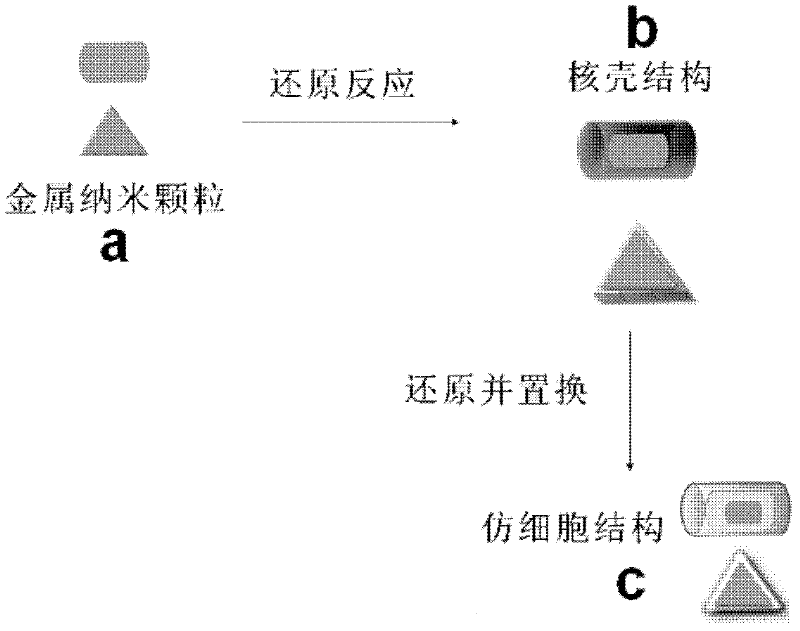

[0020] figure 1 It is a schematic diagram of the synthesis mechanism of the preparation method of the cell-like structure metal nanomaterial of the present invention.

[0021] First, on the surface of the metal nanoparticle a, the metal ions in the added metal salt solution are reduced by a reducing agent forming a core-shell structure, and another metal shell is formed on the surface of the original metal nanoparticle, thereby Construct the binary metal core-shell structure b; and then reduce the high-valence metal ions in the subsequently added metal salt solution to an intermediate low-valence state on the surface of the above-mentioned binary metal core-shell structure by forming a reducing agent that mimics the cell structure The metal ions; finally, the metal shell is sacrificed by means of the replacement reaction between the two metals to form a cell-like structure c. Since the nanostructure com...

Embodiment 2

[0036] Embodiment 2: the synthesis of nano gold sheet of imitation cell structure

[0037] The specific steps of the synthesis process of the nano-gold flakes imitating the cell structure of the present embodiment are as follows:

[0038] Step 1: Synthesis of nano-gold flake seeds: Dilute 1mL 0.01M chloroauric acid solution and 1mL 0.01M trisodium citrate solution to 40mL ice bath and mix, then add 1mL 0.1M sodium borohydride, at 1000-1500 rpm Stir for 2-4 minutes at a high speed of 10 minutes, and stand at 25-30°C for 2-4 hours.

[0039] Step 2: Mix 225mL 0.05M CTAB with 1mL 0.1M KI, 1.25mL 0.1M Ascorbic Acid, 1.25mL 0.1M NaOH and 6.25mL 0.01M Chlorauric Acid solution, then, from the Erlenmeyer flask containing 225mL of the mixture Take 22.5mL from C and put it into Erlenmeyer flask B, then take 2.25mL from Erlenmeyer flask B into Erlenmeyer flask A, finally, add 225uL seeds to Erlenmeyer flask A, quickly put the Pour the solution into the Erlenmeyer flask B, then immediate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com