Method for recovering zinc from liquid obtained by calcining, acid leaching and copper extraction of gold concentrate containing zinc and copper

A gold concentrate and acid leaching technology, applied in the field of further recovery of zinc, can solve the problems of waste of resources and no recycling, and achieve the effect of increasing the economic benefits of enterprises and improving the utilization rate of resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

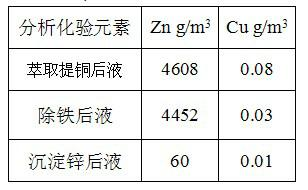

Embodiment 1

[0016] A method for recovering zinc from the solution of zinc-containing copper-gold concentrate roasted and acid leached to extract copper in this embodiment includes the following steps: after the zinc-containing copper-gold concentrate is roasted, the hot calcine is transported to the acid leaching tank by a drum , use the temperature of the hot calcined sand to control the acid leaching temperature at 80-90°C, add sulfuric acid, control the concentration of sulfuric acid to 25g / l, pass through three series-connected acid leaching tanks, stir and leaching for 5 hours, after acid leaching, the pulp is passed through a concentrator and vacuum filtration Machine-liquid-solid separation to obtain zinc-containing copper acid leaching solution and gold and silver-containing solid materials. The zinc-containing copper acid leaching solution passes through the extraction device and the electrowinning device to produce cathode copper. After extracting copper, the solution is pumped in...

Embodiment 2

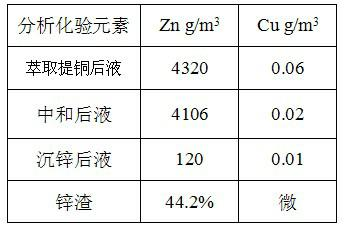

[0020] A method for recovering zinc from the solution of zinc-containing copper-gold concentrate roasted and acid leached to extract copper in this embodiment includes the following steps: after the zinc-containing copper-gold concentrate is roasted, the hot calcine is transported to the acid leaching tank by a drum , use the temperature of the hot calcined sand to control the acid leaching temperature at 85°C, add sulfuric acid, control the concentration of sulfuric acid to 30g / l, pass through three acid leaching tanks in series, stir and leaching for 6 hours, after acid leaching, the pulp is passed through the concentrator and vacuum filter liquid Solid separation, to obtain zinc-containing copper acid leaching solution and gold and silver-containing solid materials, zinc-containing copper acid leaching solution passes through extraction device and electrowinning device to produce cathode copper; after extracting copper, the liquid is pumped into the lime neutralization tank t...

Embodiment 3

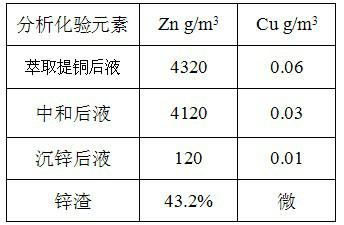

[0024] A method for recovering zinc from the solution of zinc-containing copper-gold concentrate roasted and acid leached to extract copper in this embodiment includes the following steps: after the zinc-containing copper-gold concentrate is roasted, the hot calcine is transported to the acid leaching tank by a drum , use the temperature of the hot calcined sand to control the acid leaching temperature at 90°C, add sulfuric acid, control the concentration of sulfuric acid to 35g / l, pass through three acid leaching tanks in series, stir and leaching for 7 hours, after acid leaching, the pulp is passed through a concentrator and a vacuum filter liquid Solid separation, to obtain zinc-containing copper acid leaching solution and gold and silver-containing solid materials, zinc-containing copper acid leaching solution passes through extraction device and electrowinning device to produce cathode copper; after extracting copper, the liquid is pumped into the lime neutralization tank t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com