Solar cell plate, solar cell string and solar cell assembly

A technology of solar cells and solar cells, which is applied to electrical components, circuits, photovoltaic power generation, etc., can solve the problems of complex procedures and high manufacturing costs, achieve the effect of small shading area, reduce processing procedures, and maintain photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

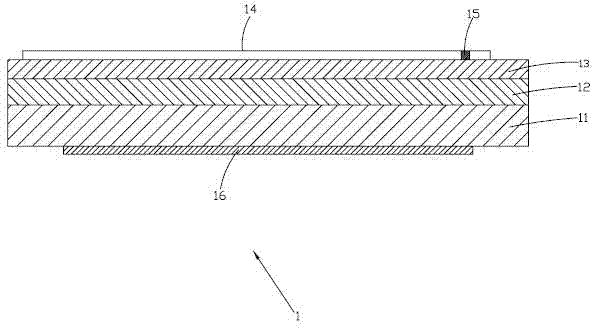

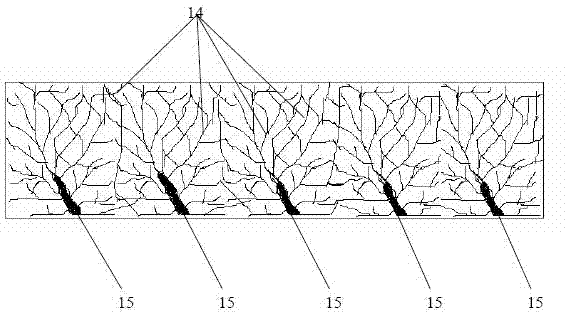

[0031] Such as figure 2 and image 3 As shown, a solar cell 1 provided in Embodiment 1 of the present invention has a length of 3-40 cm, a width of 1-15 cm, and a thickness of 0.08-2 mm. The solar cell 1 includes silicon wafers stacked in sequence 11. Diffusion layer 12 and anti-reflection film 13. The upper surface of anti-reflection film 13 is provided with several thin grid lines 14 for conducting current and at least one main grid line 15 for conducting current and having a small light-shielding area. Thin grid lines 14 are intersected or combined to form a pattern of a certain shape (such as rhombus, rectangle, dendritic or mesh shape), and each of the thin grid lines 14 is connected to at least one main grid line 15, and the silicon At least one back electric field 16 is provided on the lower surface of the sheet 11 . Wherein, the thin grid lines 14 and the main grid lines 15 are negative electrodes of the solar cell 1 , and the back electric field 16 is the positive ...

Embodiment 2

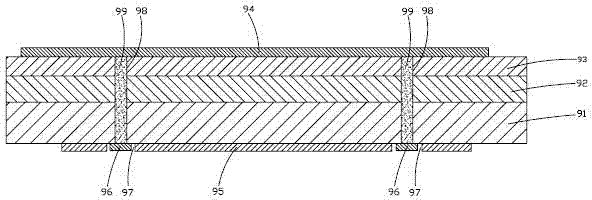

[0044] Such as Figure 5 and Figure 6 As shown, a solar cell 2 provided by Embodiment 2 of the present invention has a length of 3-40 cm, a width of 1-15 cm, and a thickness of 0.08-2 mm. The solar cell 2 includes silicon wafers stacked in sequence 21. Diffusion layer 22 and anti-reflection film 23. The upper surface of anti-reflection film 23 is provided with several thin grid lines 24 for conducting current and at least one main grid line 25 for conducting current and having a small light-shielding area. A plurality of thin grid lines 24 are intersected or combined to form a pattern of a certain shape (such as rhombus, rectangle, dendritic or mesh shape), and each thin grid line 24 is connected to at least one main grid line 25. At least one back electrode 26 and a back electric field 27 are provided on the lower surface of the silicon wafer 21 . Wherein, the thin grid lines 24 and the main grid lines 25 are negative electrodes of the solar cell 2 , and the back electrode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com