Laser bonding method for packaging of photoelectric device

A photoelectric device and bonding technology, which is applied in the field of laser bonding, can solve the problems of incomplete protection of the glass sealing body, high price, cracks in the glass substrate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

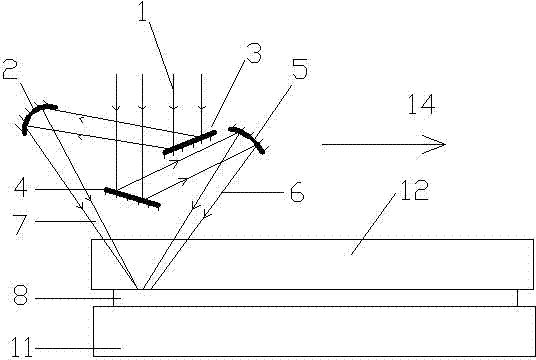

[0024] With reference to the accompanying drawings, the preferred embodiments of the present invention are described in detail as follows.

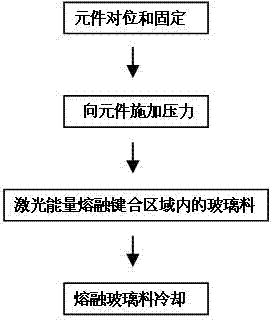

[0025] Examples see Figure 1 ~ Figure 3 , the laser bonding method that the present invention is used for optoelectronic device packaging comprises the following steps:

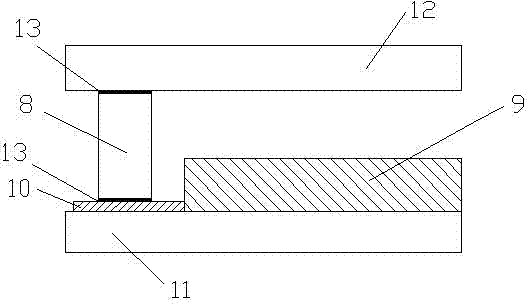

[0026] a. The glass cover plate 12 pre-sintered with the glass sealant and the glass substrate 11 deposited with the optoelectronic device 9 are accurately aligned and fixed by a fixture; the glass sealant is deposited on the edge of the glass cover plate 11 by screen printing Inside, and constitute the glass seal 8, the glass cover plate 12 and the glass substrate 11 respectively form a bonding surface area 13 in direct contact with the glass seal 8 under the action of laser energy; the optoelectronic device 9 is located inside the glass seal 8;

[0027] b. Apply initial pressure to the glass cover plate 12 and the glass substrate 11 in step a, so that the glass cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com