Permanent magnet multiple-pole switch reluctance motor

A switched reluctance and motor technology, applied in the direction of magnetic circuit rotating parts, electrical components, electromechanical devices, etc., can solve the problems of non-self-starting, increase control cost, increase magnetic energy area, etc., to protect wind abrasion loss, The effect of protecting environmental corrosion and strengthening mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below in conjunction with accompanying drawing and embodiment the present invention will be further described

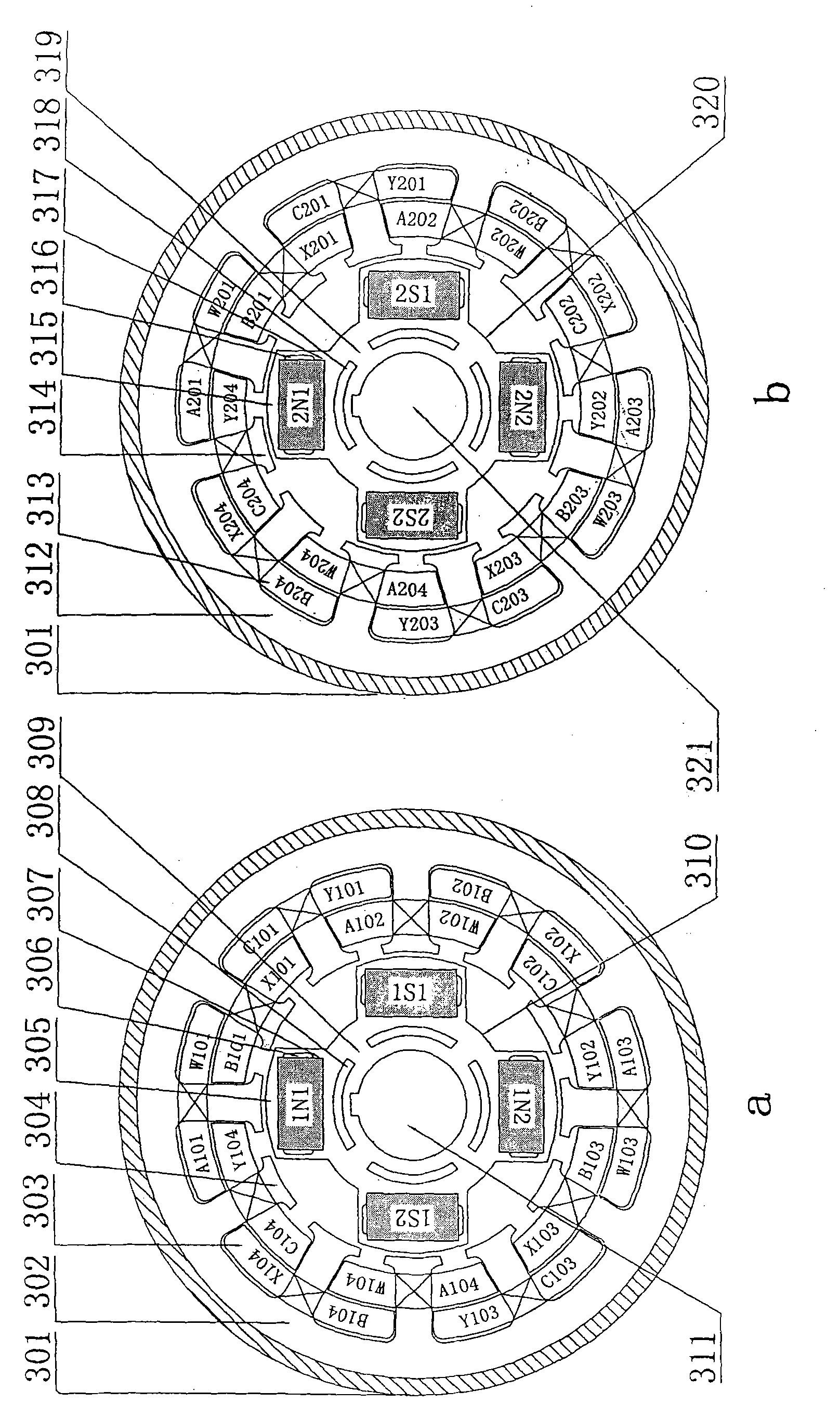

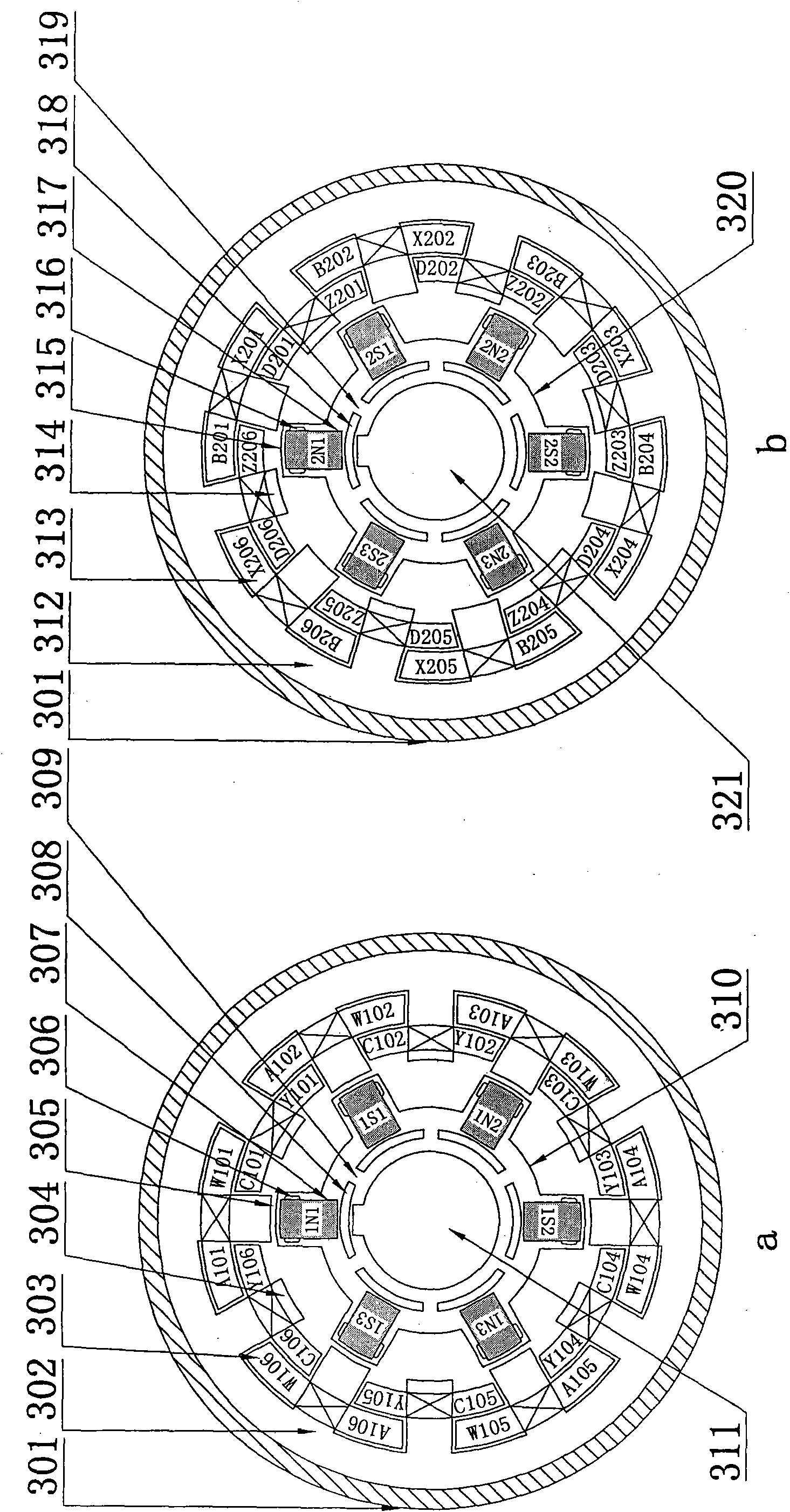

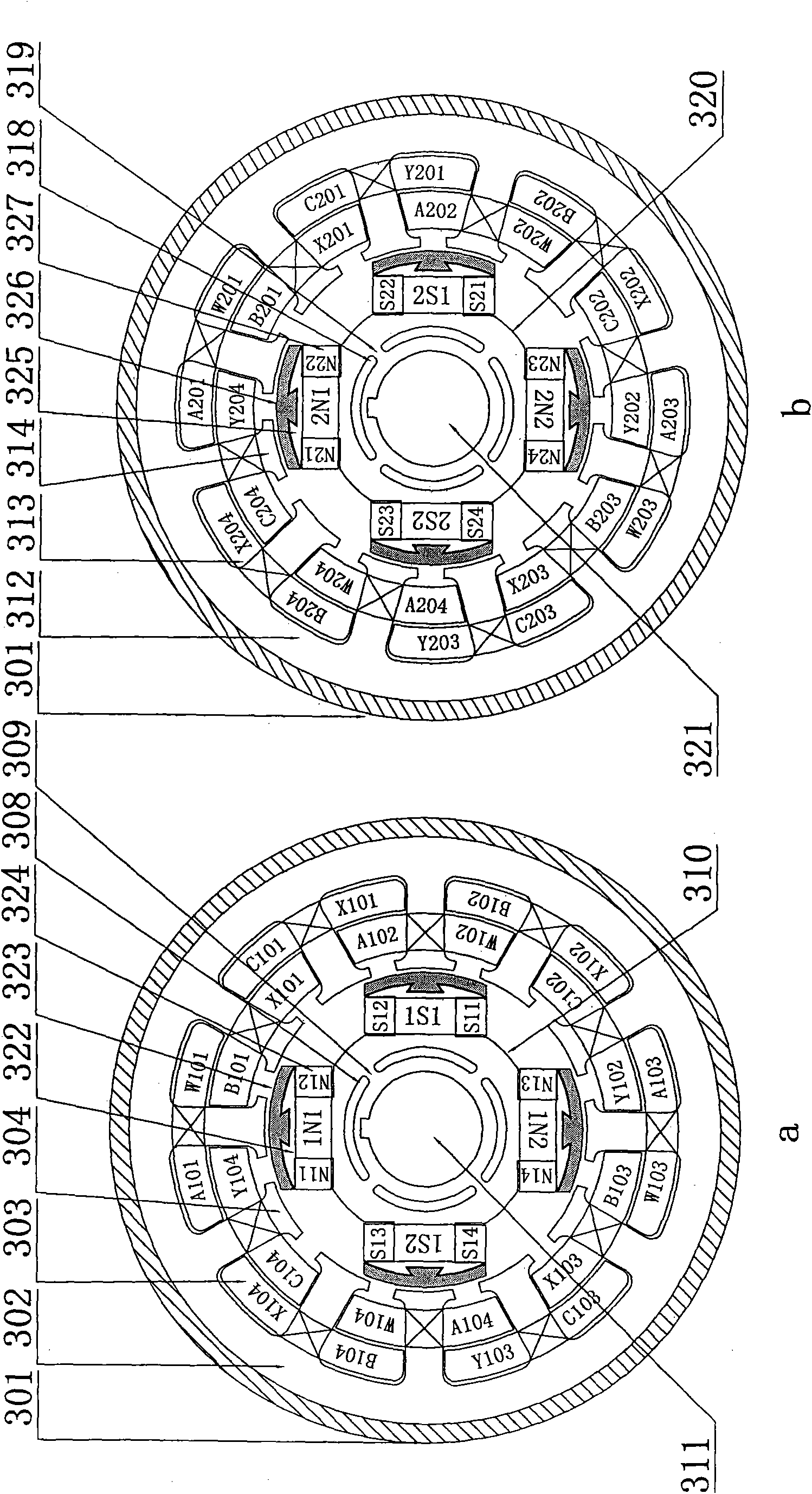

[0045] refer to figure 1 , Figure 5 , a permanent magnet multi-pole switched reluctance motor in the figure, the rotor pole is a built-in radial permanent magnet pole, the motor casing 301 is placed on the motor foot 346 through the motor foot fixing screw hole 345, and the middle part of the motor casing 301 is set There is a motor suspension ring 334, the motor front end cover 332 and the rear end cover 339 are respectively arranged on the two ends of the motor shaft through the front bearing 331 and the rear bearing 340, and the motor front end cover 332 and the rear end cover 339 are fixedly connected with the motor housing 301 through the fixing screw 333 , the outer end of the motor rear end cover 339 is provided with a windshield 344, the windshield 344 is provided with a motor fan 341, and an electronic sensor 342 is arranged between the motor fan 34...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com