Microplasma source and sterilization system including the same

一种微等离子体、灭菌系统的技术,应用在离子体产生装置领域,能够解决难以覆盖、困难性提升、灭菌的成效受制待处理物几何形状等问题,达到增加使用安全性、利于操作的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

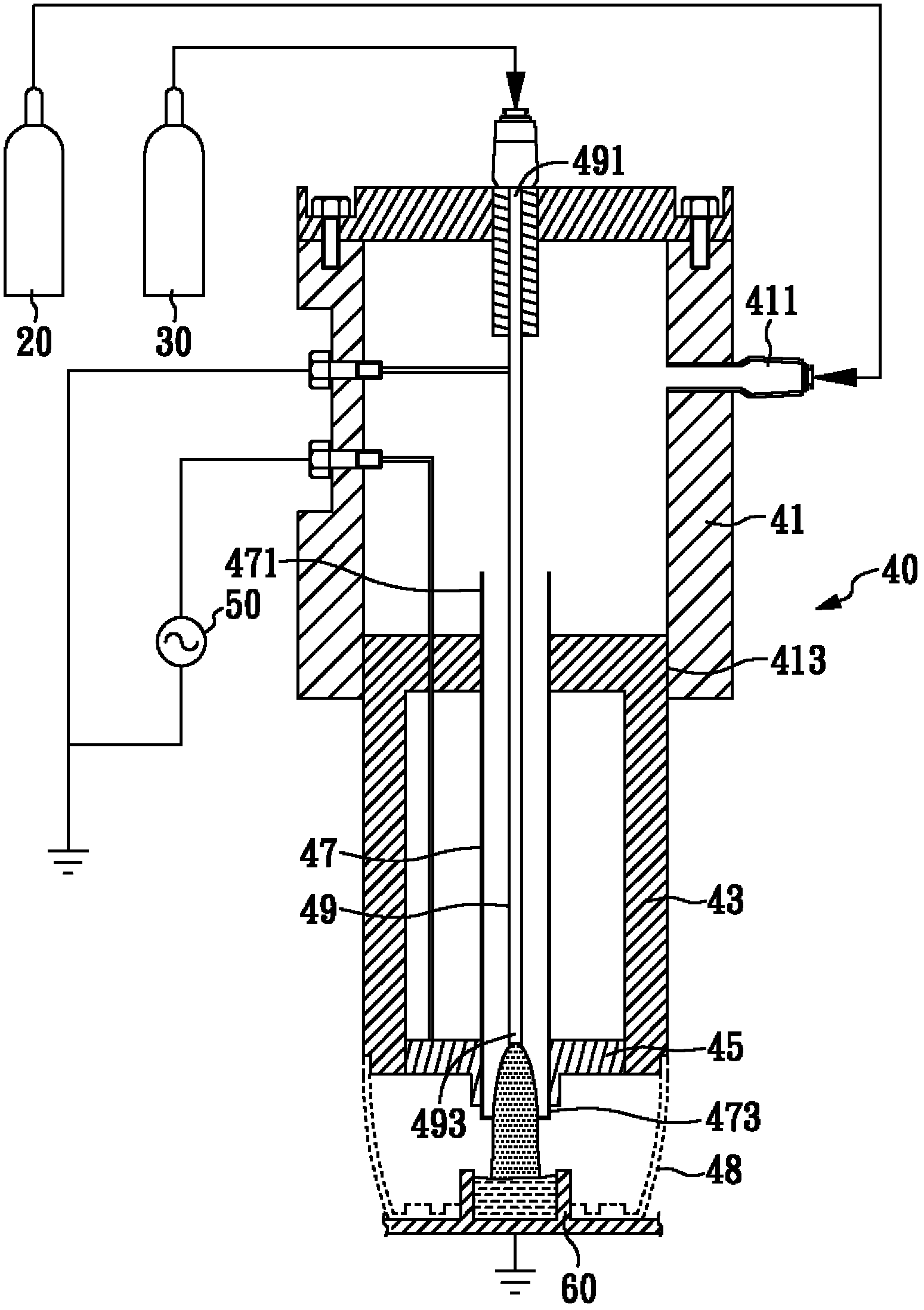

[0055] figure 1 is a schematic diagram of the micro-plasma generating device of this embodiment. Such as figure 1 As shown, the micro plasma generation device of the present invention mainly includes: a first gas storage unit 20 , a second gas storage unit 30 , a micro plasma generation unit 40 , and a power supply unit 50 .

[0056] In the present invention, the first gas storage unit 20 is used to store a first gas, and the second gas storage unit 30 is used to store a second gas. In this embodiment, the first gas is used as a plasma excitation gas, such as argon, and the second gas is used as a reactive gas, such as oxygen.

[0057] The micro-plasma generating unit 40 mainly includes: a gas transmission cavity 41, which has a first inlet port 411 and a first outlet port 413, wherein the first inlet port 411 is connected to the first gas storage unit 20 and Input the first gas; a heat dissipation protection cavity 43, which has the functions of heat dissipation and protec...

Embodiment 2

[0061] The micro plasma sterilization system of the present embodiment, as figure 1 As shown, it mainly includes: a first gas storage unit 20 , a second gas storage unit 30 , one or a plurality of micro plasma generation units 40 , and a power supply unit 50 . The structure of the micro-plasma sterilizing system of this embodiment is substantially the same as that of Embodiment 1, and in addition to the above-mentioned components, an additional sample tank 60 may be provided as required for accommodating solid samples or liquid samples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com