Wall surface paint composition and preparation method thereof

A composition and wall paint technology, applied in anti-corrosion coatings, multi-color effect coatings, anti-fouling/underwater coatings, etc., can solve the problems of easy mildew, improper component distribution, poor adhesion, etc., and achieve a simple preparation process. , cost-effective, strong adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

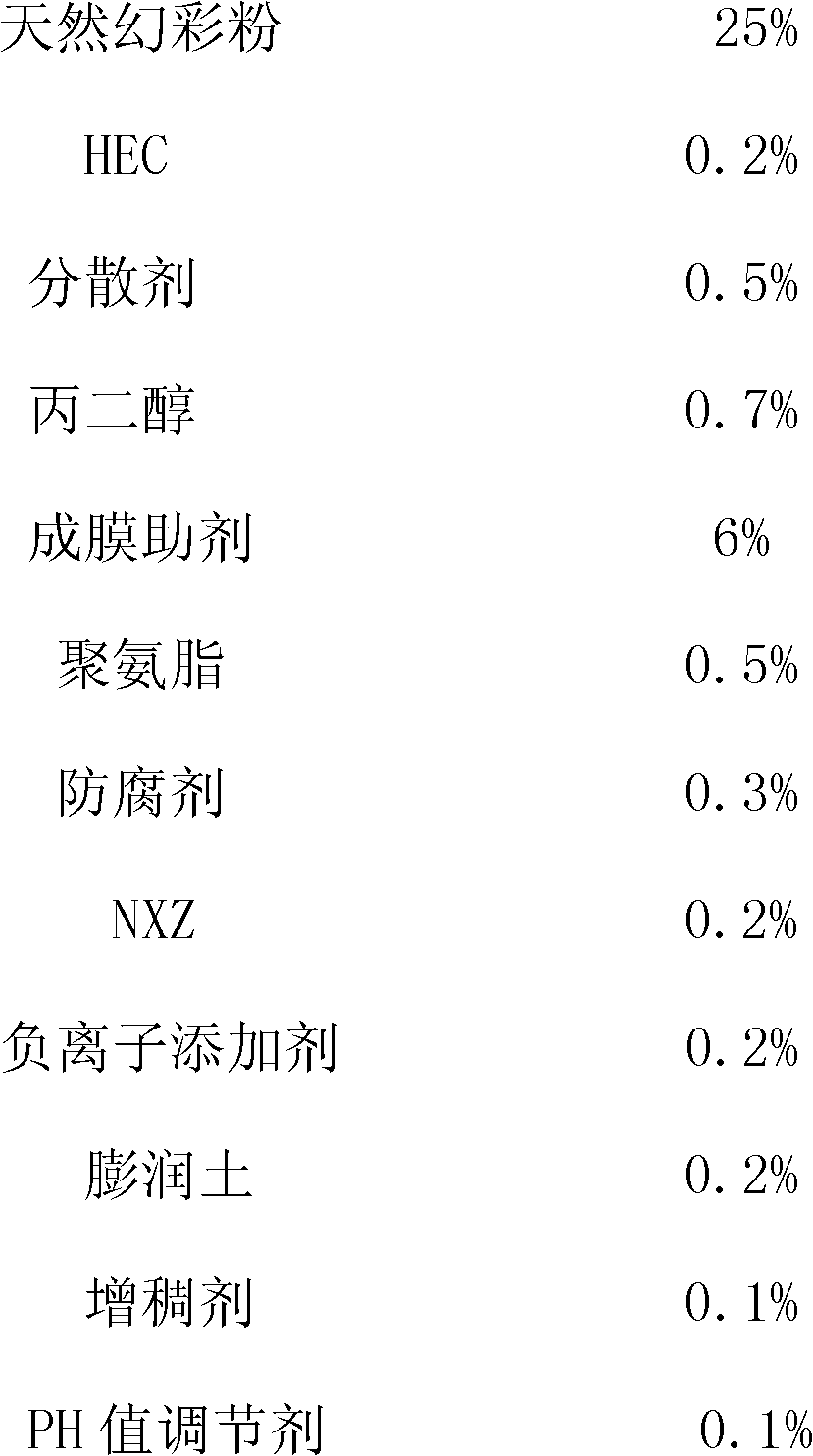

Embodiment 1

[0024] Wash the stainless steel reaction tank, add 36% of total weight of water, 2% of HEC, add 0.5% of total weight of dispersant, adjust the mixer to 1200 rpm, stir for 25 minutes, mix well, and let stand for 5 minutes. Add 25% magic color powder, 30% pure acrylic emulsion, 6% film-forming aid, 0.2% negative ion additive of total weight again, stirrer is adjusted to 400 revs / min, low speed stirs 30 minutes. Then add 0.5% polyurethane, 0.2% bentonite, 0.2% NXZ, adjust the pH value to 8-9, adjust the speed to 400 rpm, stir for 15 minutes, and wait for half an hour before filling the paint to make a nanocomposite Invisible illusion paint.

[0025] The product quality reaches: (1) state in the container: no hard lumps, uniform state after stirring; (2) construction: two coats without obstacles; (3) appearance of the coating film: normal appearance; (4) low temperature stability: No deterioration; (5) Contrast ratio / %: ≥0.95; (6) Drying time (surface dry) / h: ≤2 hours; (7) voc / g....

Embodiment 2

[0027] Clean the stainless steel reaction tank or homogenizer, the first step: mix water, HEC, dispersant and other additives first; the second step: add negative ion additives, magic powder, pure acrylic emulsion, film-forming aids, HEC Mix evenly, adjust the mixer to 1200 rpm, stir and cut at high speed for 20 minutes; the third step: add polyurethane, leveling agent, NXZ, pH regulator, adjust the speed to 400 rpm, and stir at low speed for 20 minutes. That is to make nano-composite invisible illusion paint, filter and pack.

[0028] The product quality reaches: (1) state in the container: no hard lumps, uniform state after stirring; (2) construction: two coats without obstacles; (3) appearance of the coating film: normal appearance; (4) low temperature stability: No deterioration; (5) Contrast ratio / %: ≥0.95; (6) Drying time (surface dry) / h: ≤2 hours; (7) voc / g.L-1: ≤120; (8) Alkali resistance (dipping 96h): no abnormality; (9) free formaldehyde / g.kg-1: 0.1; (10) soluble c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com