Energy-saving ecological distillation oil baking device

An ecological and oiler technology, applied in the production of fat, essential oils/spices, etc., can solve the problems of wood consumption, irregular operation, environmental pollution, etc., and achieve the effect of improving production efficiency and shortening distillation cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing, further illustrate positive technical effect of the present invention with example.

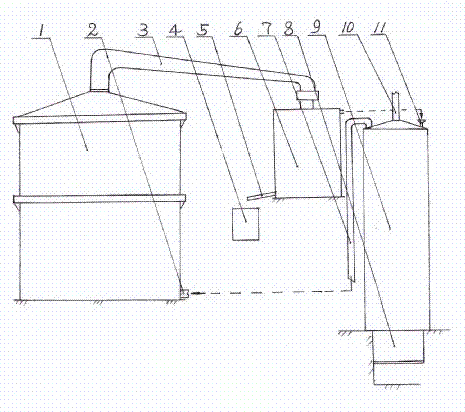

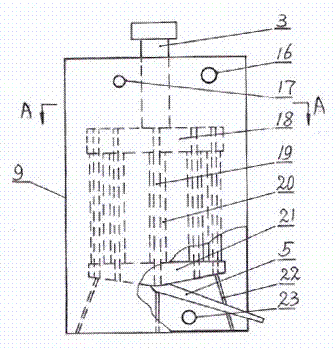

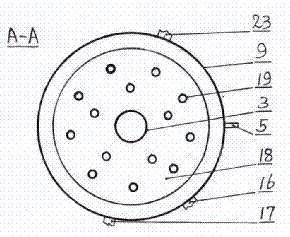

[0028] like Figure 1-8 As shown, the steamer 1 is divided into two sets, and can also be set as more sets as required. Each set is provided with beams or grids for placing materials that need to be distilled. Positioning bar 29 is arranged on the retort inner wall, so that the retort on the stage is fixedly connected accurately. Also be welded with annular water seal groove 27 on the lower stage retort outer wall, put water in the groove and immerse upper stage retort and lower stage retort connection mouth into water and seal. Weld some slanting braces 32 between the water seal tank and the lower platform retort to enhance the strength of the water seal tank. There is an annular or T-shaped steam spraying pipe connected to the steam inlet 2 at the bottom of the lowermost platform retort. There are spray holes on the upper side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com