Deformed steel bar rust preventing agent and preparation method thereof

A manufacturing method and technology of anti-rust agent, applied in the anti-rust field of rebar, can solve problems such as easy rusting of rebar rolled steel, and achieve the effect of accelerating the speed of phosphating and film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

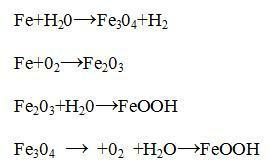

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: 10% zinc dihydrogen phosphate and 50% solvent are miscible in the reactor, and then add 2% ammonium persulfate; after the solution is still for 45 minutes, add 2% ammonium chloride to the solution several times; Add 6% ammonium nitrate, then add 30% solvent, mix for 30 minutes, and discharge the material statically to generate rebar rust inhibitor. The solvent is distilled water; the above ratios are percentages by weight.

Embodiment 2

[0016] Embodiment 2: 5% zinc dihydrogen phosphate and 50% solvent are miscible in the reactor, and then add 1% ammonium persulfate; after the solution is still for 45 minutes, add 1% ammonium chloride to the solution several times; Add 3% ammonium nitrate, then add 40% solvent, mix for 30 minutes, and discharge the material statically to generate rebar rust inhibitor. The solvent is distilled water; the above ratios are percentages by weight.

Embodiment 3

[0017] Embodiment 3: 15% zinc dihydrogen phosphate and 50% solvent are miscible in the reactor, and then add 3% ammonium persulfate; after the solution is still for 45 minutes, add 3% ammonium chloride to the solution several times; Add 10% ammonium nitrate, then add 19% solvent, mix for 30 minutes, and discharge the material statically to generate rebar rust inhibitor. The solvent is distilled water; the above ratios are percentages by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com