Surface formwork system for building with frame structure and application thereof

A frame structure and building surface technology, which is applied in the direction of architecture, building structure, formwork/formwork components, etc., can solve the problems of high deformation stiffness, limited fiber reinforcement effect, and increased cost, and achieve enhanced longitudinal bending and torsion resistance Effects of rigidity, cost reduction and difficulty of assembly and disassembly, and service life extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Such as Figure 4 and Figure 5 The building face formwork system with frame structure of the present invention is shown, which is composed of face formwork units and frame structures.

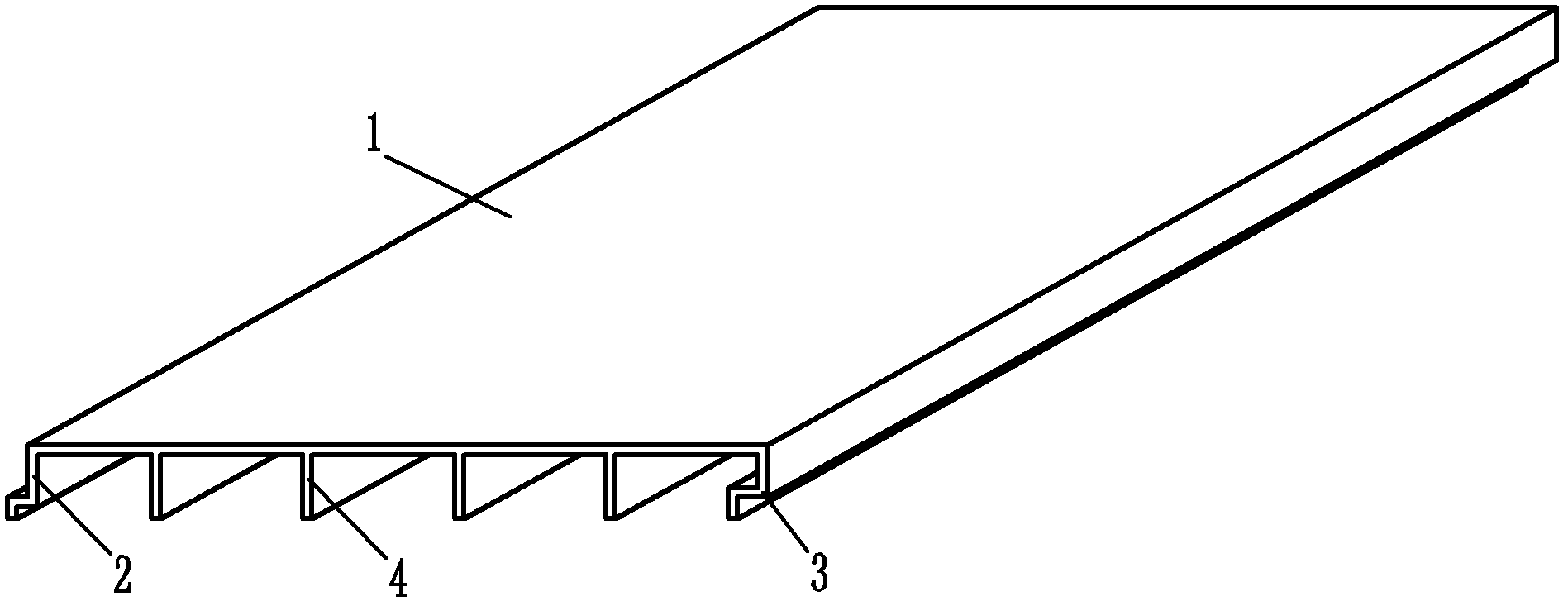

[0041] The surface formwork unit 1 is made of wood-plastic composite material. The longitudinal sides of the formwork unit 1 are respectively provided with connecting ribs 2 and 3, wherein the connecting rib 2 on one side is provided with protrusions, and the connecting rib 3 on the other side is provided with corresponding Grooves are set, and the wood-plastic surface formwork unit 1 is also provided with reinforcing ribs 4 along the longitudinal direction of its plate body. The reinforcement ribs 4 and the connecting ribs 2 and 3 are located on the same side of the wood-plastic surface formwork unit 1, specifically as figure 1 shown. frame structure such as image 3 shown, including figure 2 The longitudinal link 5 and the transverse link 9 are shown, and the longitudinal link 5 ...

Embodiment 2

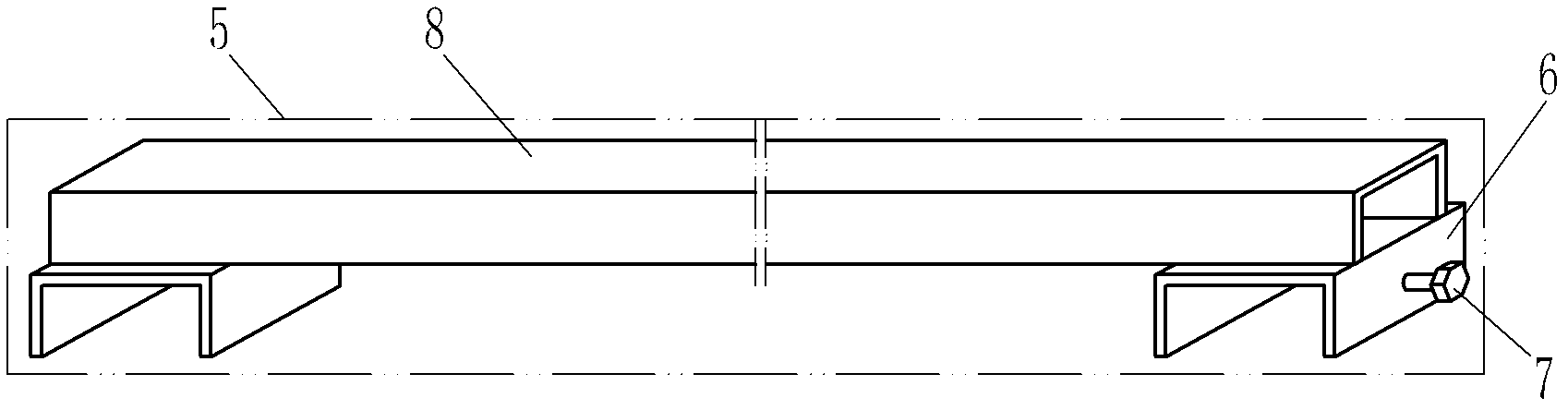

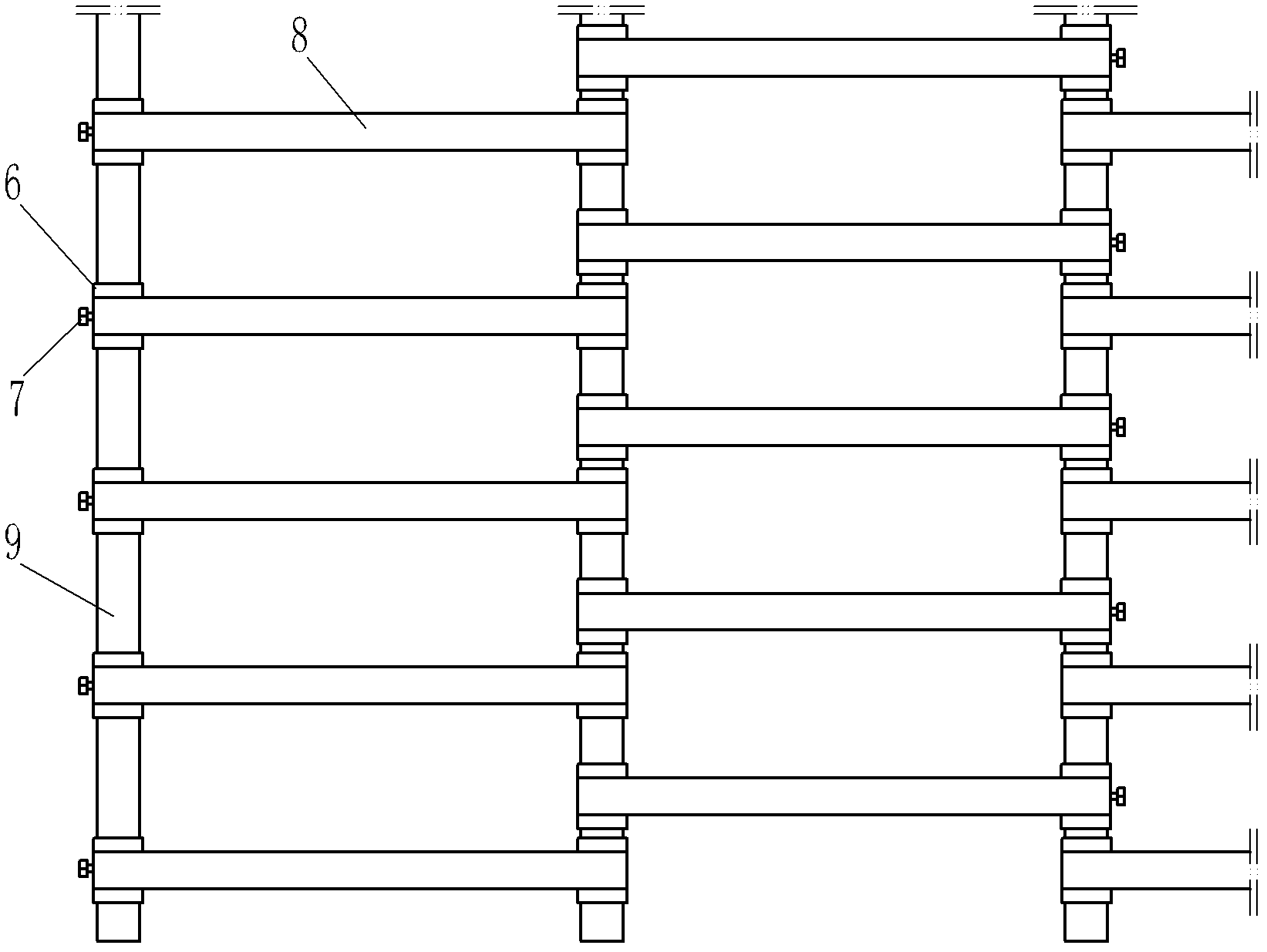

[0048] Such as Figure 8 The difference between the building surface formwork system with frame structure of the present invention shown in Embodiment 1 is that the longitudinal link structure in the frame structure can be varied, such as Figure 6 As shown, the longitudinal connecting rod includes a supporting connecting rod 8 made of steel pipe and a connecting piece 6 made of channel steel, and fastening screws 7 are arranged on the outer end faces of the connecting piece 6 on both sides. Correspondingly, yes Figure 7 As shown, in the surface formwork unit 1 used, the size of the gap between the reinforcing ribs 4 is adapted to the size of the supporting link 8 .

[0049] Transverse connecting rod 9 made of channel steel and Figure 6 The frame structure formed by the longitudinal links shown, with Figure 6 When the surface formwork unit shown constructs the building surface formwork system with frame structure of the present invention, the process can refer to the pro...

Embodiment 3

[0052] Such as Figure 9 The difference between the building surface formwork system with a frame structure of the present invention and the first embodiment is that the frame structure also includes columns 11 . When building a frame structure, such as Figure 10 As shown, the threaded hole on the connecting block 12 fixedly welded inside the transverse connecting rod 9 cooperates with the screw rod 13 fixedly arranged on the top of the column 11 to realize the fixed connection between the column 11 and the transverse connecting rod 9 . The longitudinal link 5 is still erected on the transverse link 9 by means of the connectors provided at both ends.

[0053] Due to the addition of uprights 11, the building surface formwork system with frame structure of the present invention described in this example can be used to construct building formwork systems of various heights in addition to the advantages described in Embodiment 1. The applicability is stronger.

[0054] Based o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com