Power head of rear cover-plate type rotary drilling rig and installation method thereof

A technology of a rotary drilling rig and an installation method, which is applied to rotary drilling rigs, drilling equipment and methods, percussion drilling, etc., and can solve problems such as difficulty in increasing the output torque, smaller space in the main box, and poor rigidity, and achieve The reduction ratio is increased, the output torque is large, and the effect of large output torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

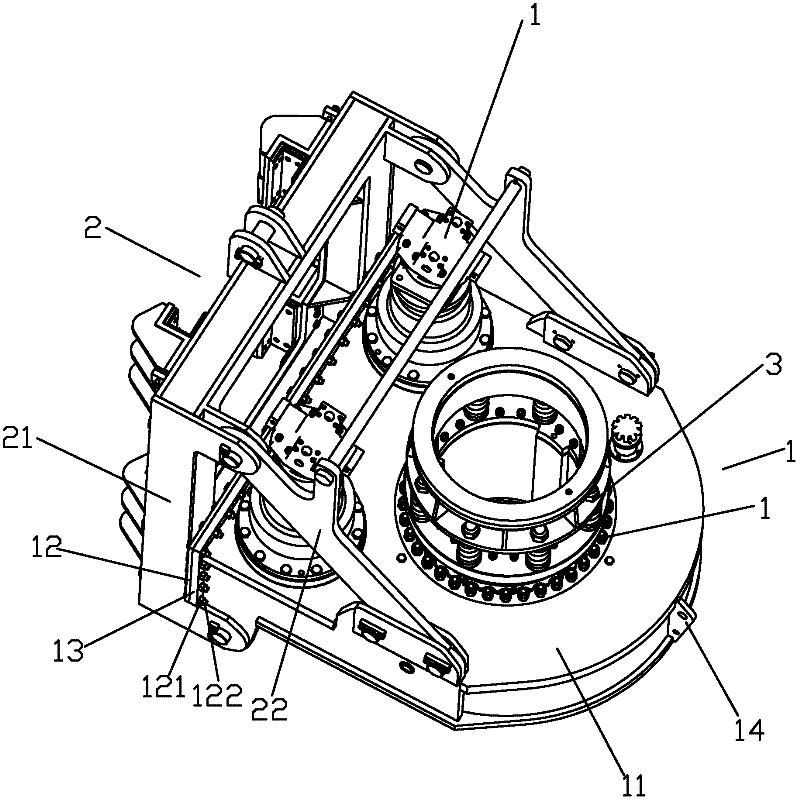

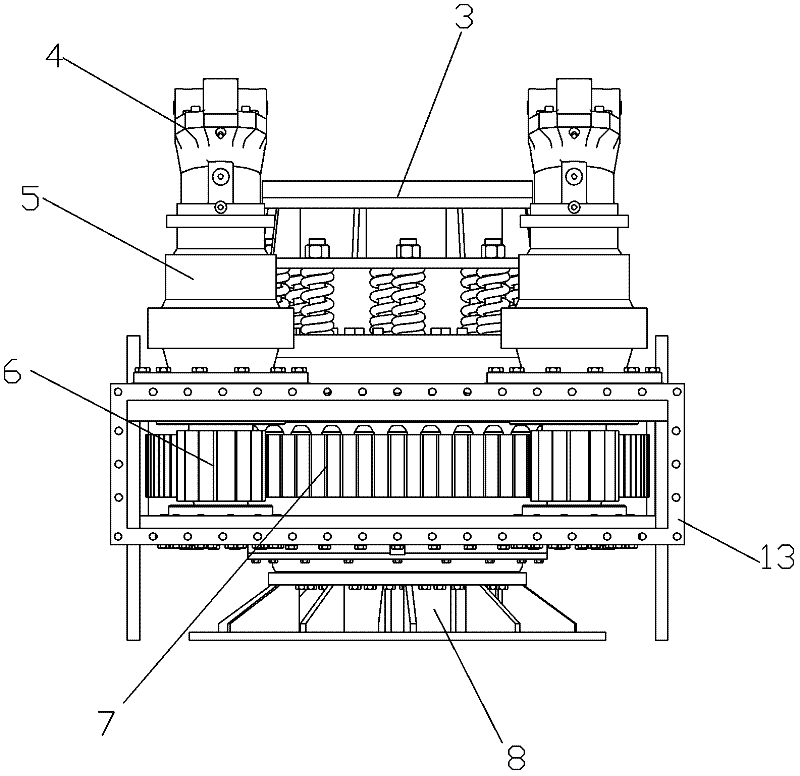

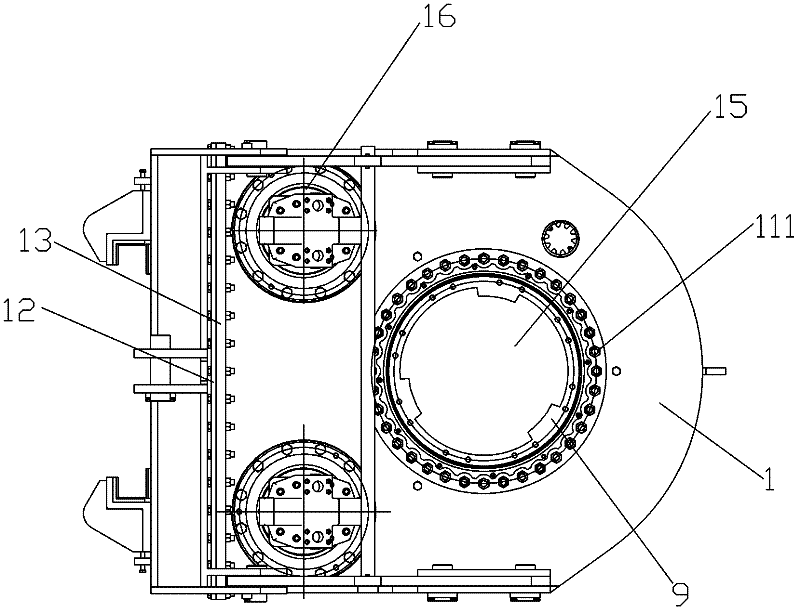

[0031] Examples, see Figure 1 to Figure 4 As shown, the power head of a back cover type rotary drilling rig of the present invention is a double hydraulic motor drive type, which includes a carriage device 2, two hydraulic motors 4, two planetary reducers 5, two active Gear 6, a driven gear 7, a gear housing 1, a drive sleeve 9, a buffer device 3 and a pressure plate device 8. The gear case 1 comprises a rear cover plate 12 and a main case 11 with an integral structure and an opening on the rear side. The top end of the main case 11 is provided with a first mounting hole 15 and two holes for installing the driving gear. A third mounting hole 16, correspondingly, the bottom end surface of the main box body 11 is provided with a second mounting hole 17 coaxial with the first mounting hole 15 and two coaxial with the two third mounting holes 16 respectively The fourth installation hole 18 , wherein the diameter of the second installation hole 17 is larger than the diameter of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com