Honeysuckle flower drying oven and method capable of realizing field processing

A technology of processing honeysuckle from the origin, which is applied in the field of drying ovens for honeysuckle, which can solve the problems of short drying time, uneven quality, unhygienic and other problems, and achieve the effect of good flower shape of decoction pieces, light green color of tea soup, and mellow aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

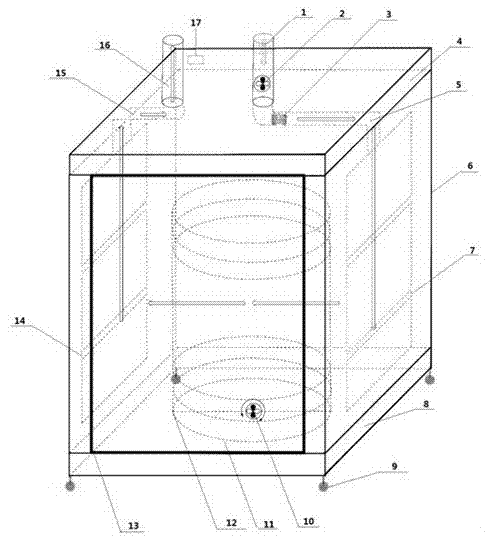

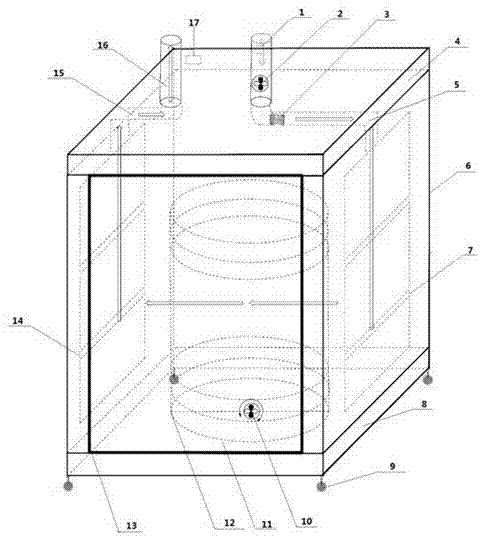

[0050] The present invention can realize the honeysuckle drying method of production area processing, and adopts such as figure 1 The shown drying oven for honeysuckle that can realize processing at the origin is used to dry and process the honeysuckle;

[0051] The drying oven for honeysuckle includes a box body 6, and a baking tray 11 is arranged in the box body 6. The baking tray 11 is supported by a baking tray bracket 12; Clockwise rotation;

[0052] The top of the box body 6 is provided with an air inlet channel and an air exhaust channel 16. The air inlet channel is connected to the hot air channel 5, and the hot air channel 5 is connected to the hot air distributor 7; distributor 14;

[0053] The inlet of the air inlet channel is provided with an air inlet filter 1, and a blower motor 2 and a heating device 3 are arranged in the air inlet channel;

[0054] The heating device 3 can be an electric heating device, and can also provide a heat source by means of anthracite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com