Exposure method adopting lithography machine

An exposure method and technology of lithography machine, applied in the field of lithography machine exposure, can solve problems such as chip deformation, and achieve the effect of the best process registration progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be described in detail below. It should be noted that the embodiments described here are for illustration only, and are not intended to limit the present invention.

[0027] Figure 4 Exemplary shows the flow chart of the exposure method of the lithography machine of the present invention, including

[0028] Step 101, transfer the silicon wafer to the silicon wafer loading stage.

[0029] Step 102, turn on the vacuum equipment to make the silicon wafer carrier absorb the silicon wafer.

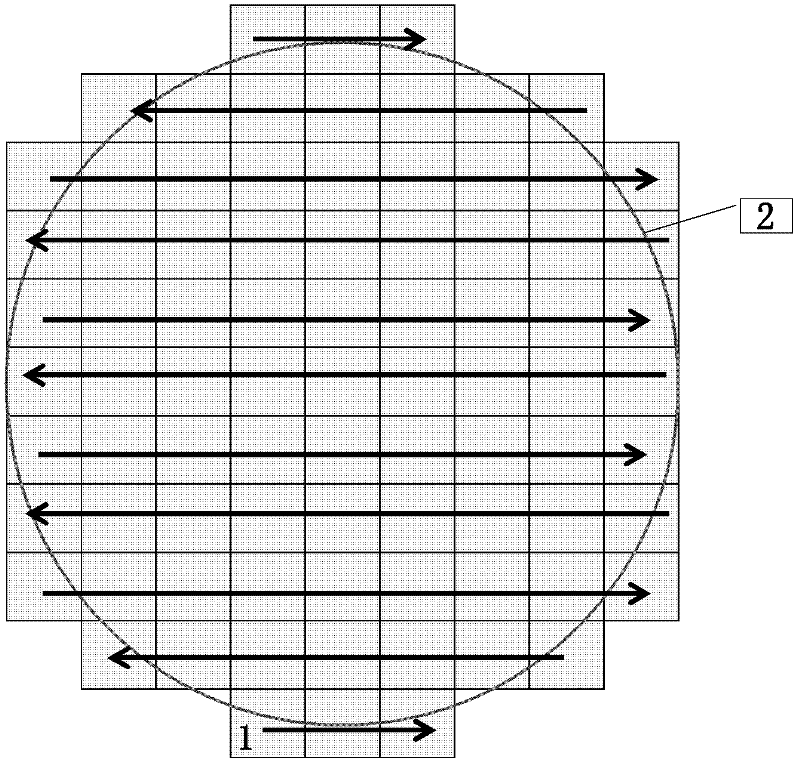

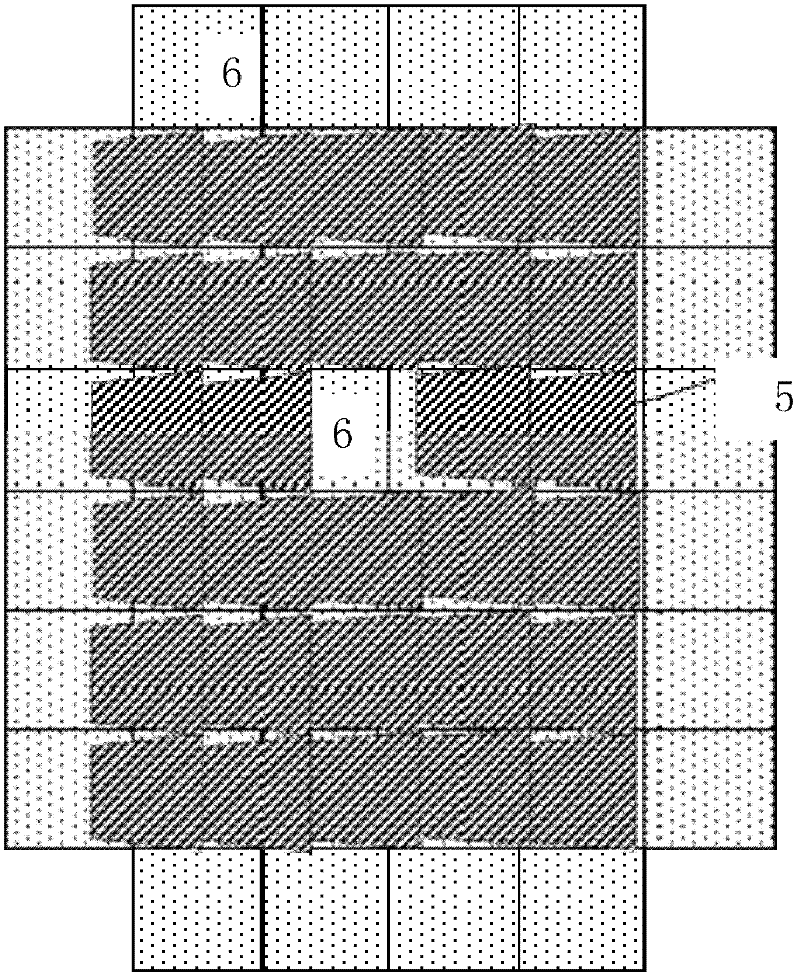

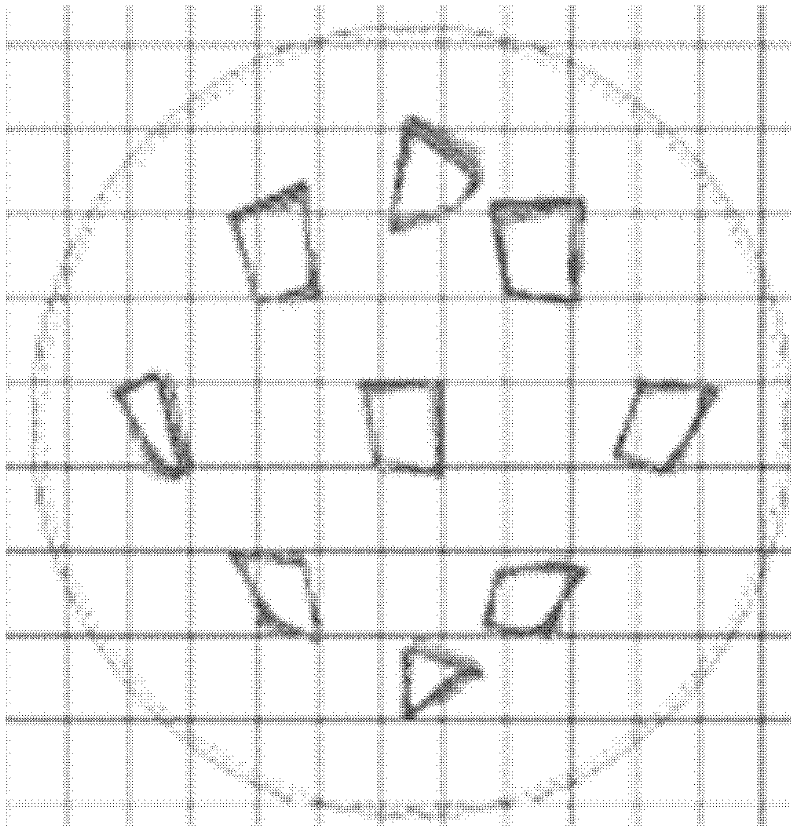

[0030] Step 103 , perform alignment, and expose the chips on the silicon wafer in batches, wherein the chips are exposed at intervals on the exposure path during each batch of exposure.

[0031] The implementation process of the exposure method for the lithography machine of the present invention will be described in detail below.

[0032] If the traditional continuous exposure method is adopted, the exposed chip will be deformed due to high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com