Method for determining normal vector of wallboard curved surface

A technology of normal vector and surface method, which is applied in the field of determining the normal vector of the wall panel surface, and can solve problems such as low measurement efficiency, lost application prerequisites, and a large number of discrete point coordinates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Describe the present invention below in conjunction with specific embodiment:

[0026] The panel workpiece that adopts in the present embodiment, its theoretical surface equation in the numerical control system of automatic drilling and riveting machine is x 2 / 4+y 2 / 25-z 2 / 9=1, the theoretical coordinates of the riveting point M to be drilled on the wall plate workpiece are (5.000, 1.000, 6.900), and the theoretical normal vector of the riveting point M to be drilled is N s =(2.5000, 0.0800, 1.5333).

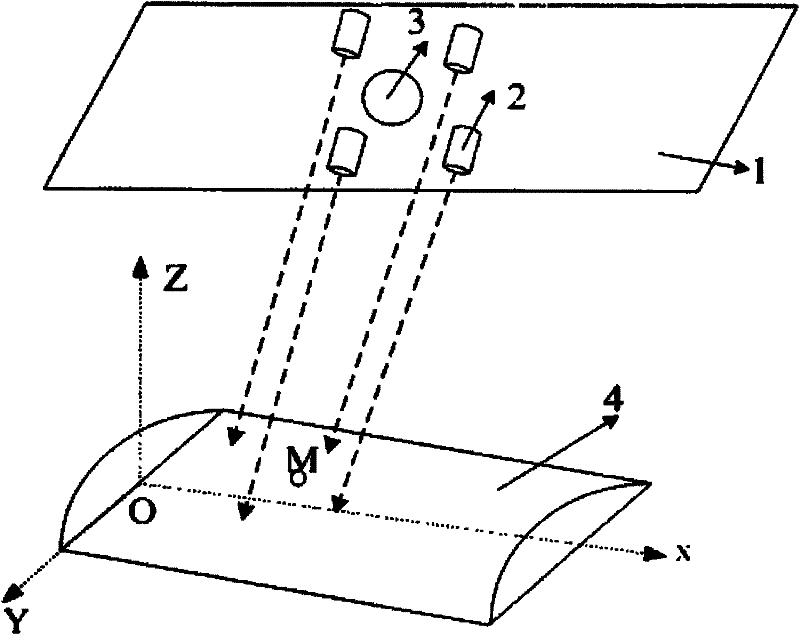

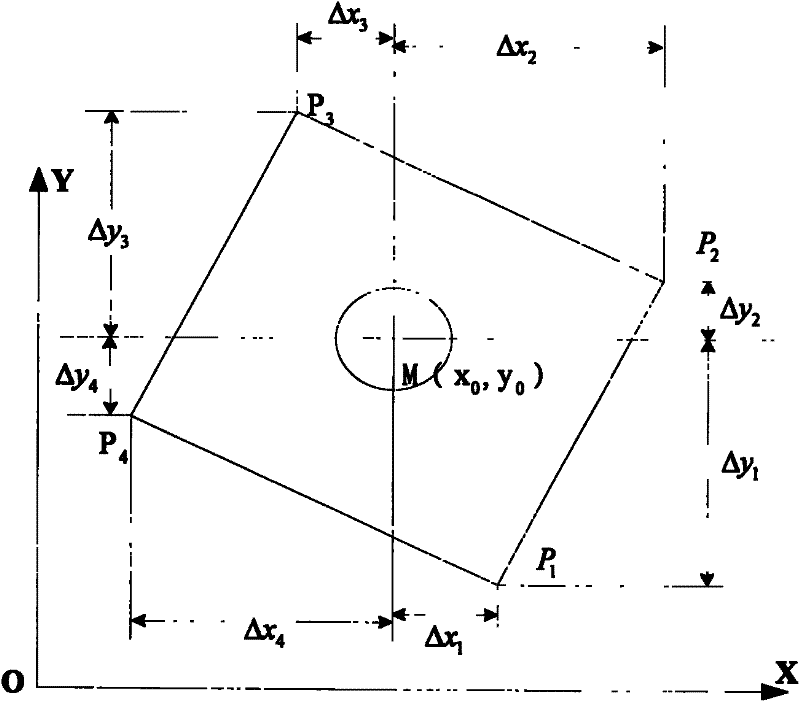

[0027] Step 1: Install the wallboard workpiece 4 on the working table of the automatic drilling and riveting machine and set the knife. Four laser distance measuring sensors 2 are installed around the power head 3 of the automatic drilling and riveting machine. The ends are on the same plane, and the ends of the four laser ranging sensors 2 are at the same distance from the working table of the automatic drilling and riveting machine, and the distance is H=30.

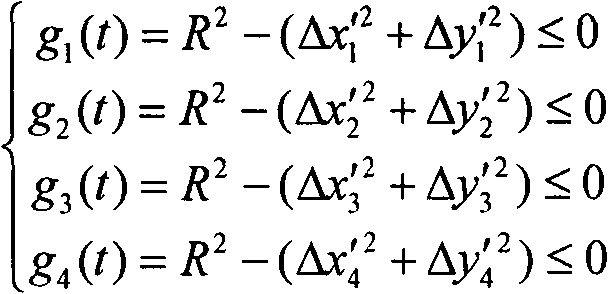

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com