Preparation method of polyimide porous film

A polyimide and porous film technology, which is applied in the field of preparation of polyimide porous films, can solve the problems of uneven distribution, difficult control of pore size, etc., and achieves simple preparation process, uniform and orderly distribution of pores, and controllable pore size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Use 4,4'-diaminodiphenyl ether and pyromellitic dianhydride as monomers and N,N-dimethylformamide (DMF) as solvent to prepare viscous polyamic acid (PAA) solution . A PAA solution with a mass fraction of 3% and silicon dioxide (SiO2) with a particle size of 380 nm 2 ) colloidal balls according to the mass ratio PAA: SiO 2 =7:3 mixing, ultrasonic stirring for 3 hours to obtain a clear solution;

[0025] (2) The above PAA / SiO 2 The solution was coated on a glass plate and dried in vacuum at 60°C (vacuum degree: 0.005 MPa) to obtain PAA / SiO 2 Composite film; the PAA / SiO 2 The composite film is heated at 100°C, 200°C, and 300°C for 1 hour for imidization to obtain a polyimide / silicon dioxide composite film;

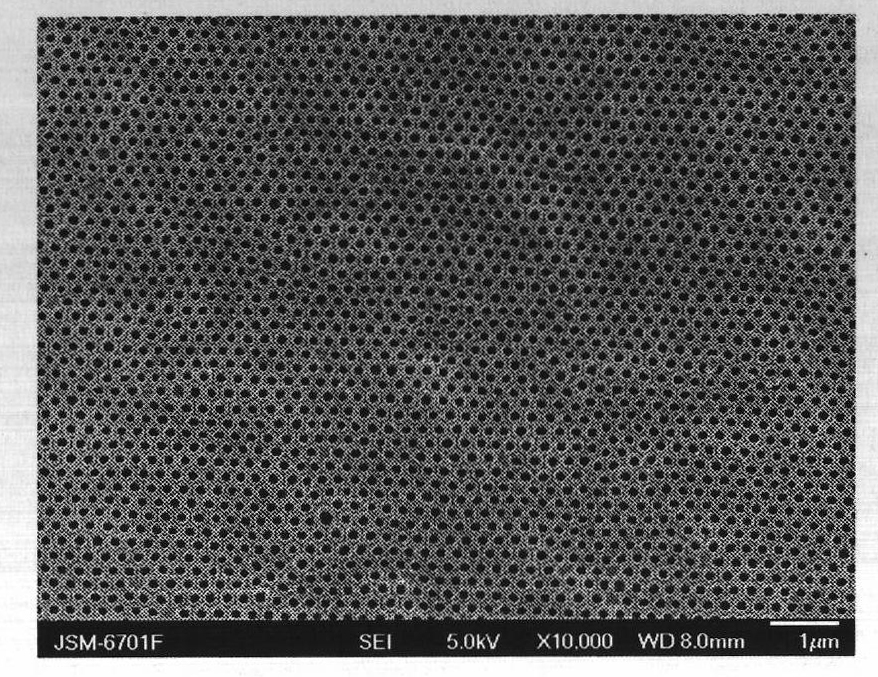

[0026] (3) Detach the polyimide / silicon dioxide composite film from the glass plate and immerse it in 10% HF solution to etch and remove SiO 2 The colloidal spheres obtained a structured porous polyimide film. The porosity of the obtained ordered polyimide p...

Embodiment 2

[0028] Prepare polyimide porous material according to the method in embodiment 1, difference is that the mass fraction concentration of polyamic acid is 6%, SiO 2 The mass ratio of colloidal balls to polyamic acid is 1:1. The porosity of the obtained ordered polyimide porous film is 40%, and the SEM electron microscope results show that the surface pore diameter of the film is 140 nanometers, and the internal pore diameter is 380 nanometers.

Embodiment 3

[0030] Prepare polyimide porous material according to the method in embodiment 1, the difference is the selected SiO 2 The particle size of the colloidal ball is 1.2 microns, polyamic acid and SiO 2 The mass ratio of colloidal spheres is 8:2, and the porosity of the obtained ordered polyimide porous film is 15%. The results of SEM electron microscopy show that the surface pore diameter of the film is 410 nanometers, and the internal pore diameter is 1.1 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Surface aperture | aaaaa | aaaaa |

| Internal aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com