Polymer tissue engineering scaffold porous material with good pore connectivity and preparation method thereof

A technology of hole connectivity and tissue engineering, applied in medical science, prosthesis, etc., can solve problems such as poor connectivity and limited cell culture, and achieve the effect of low cost, good connectivity and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

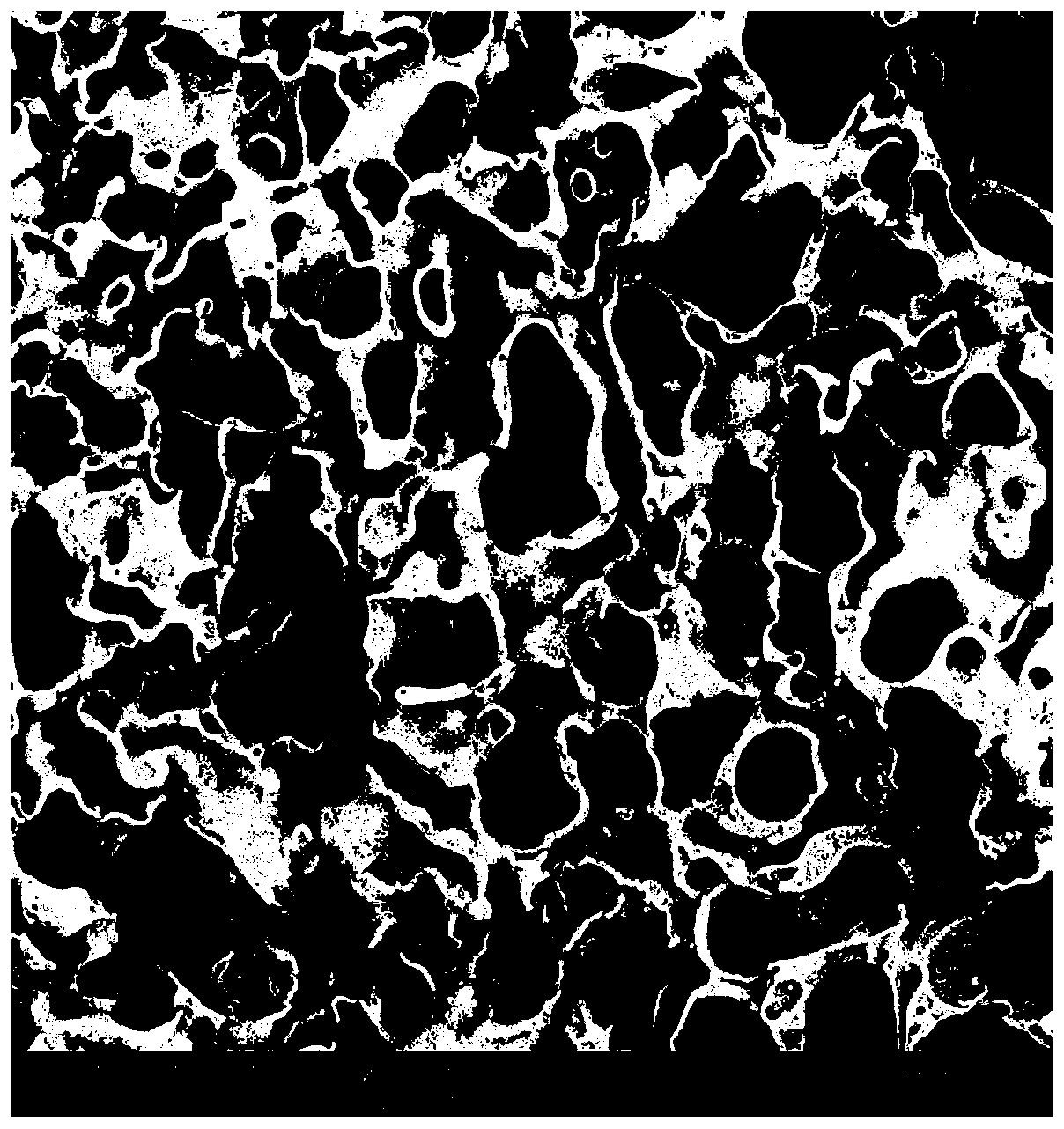

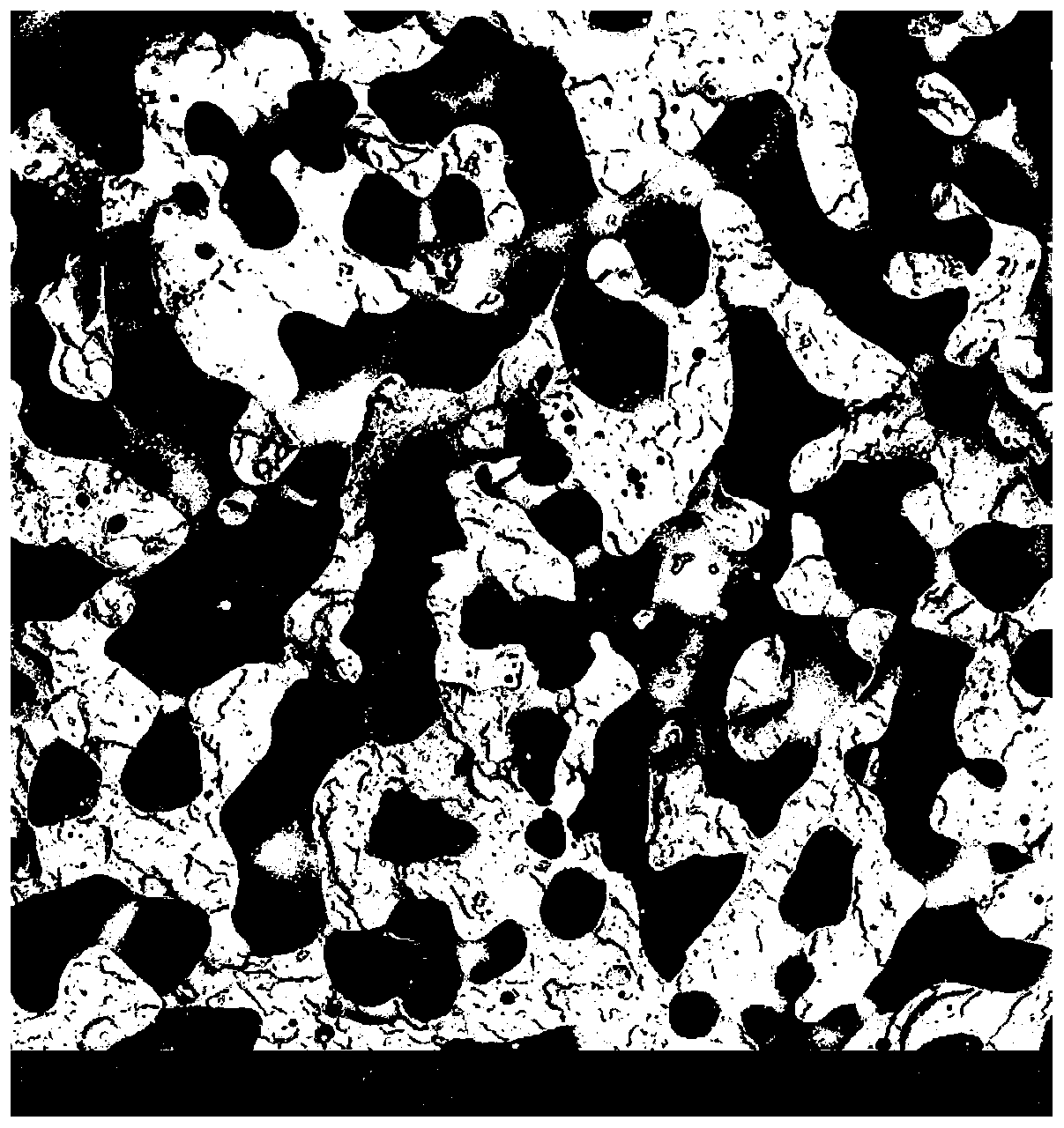

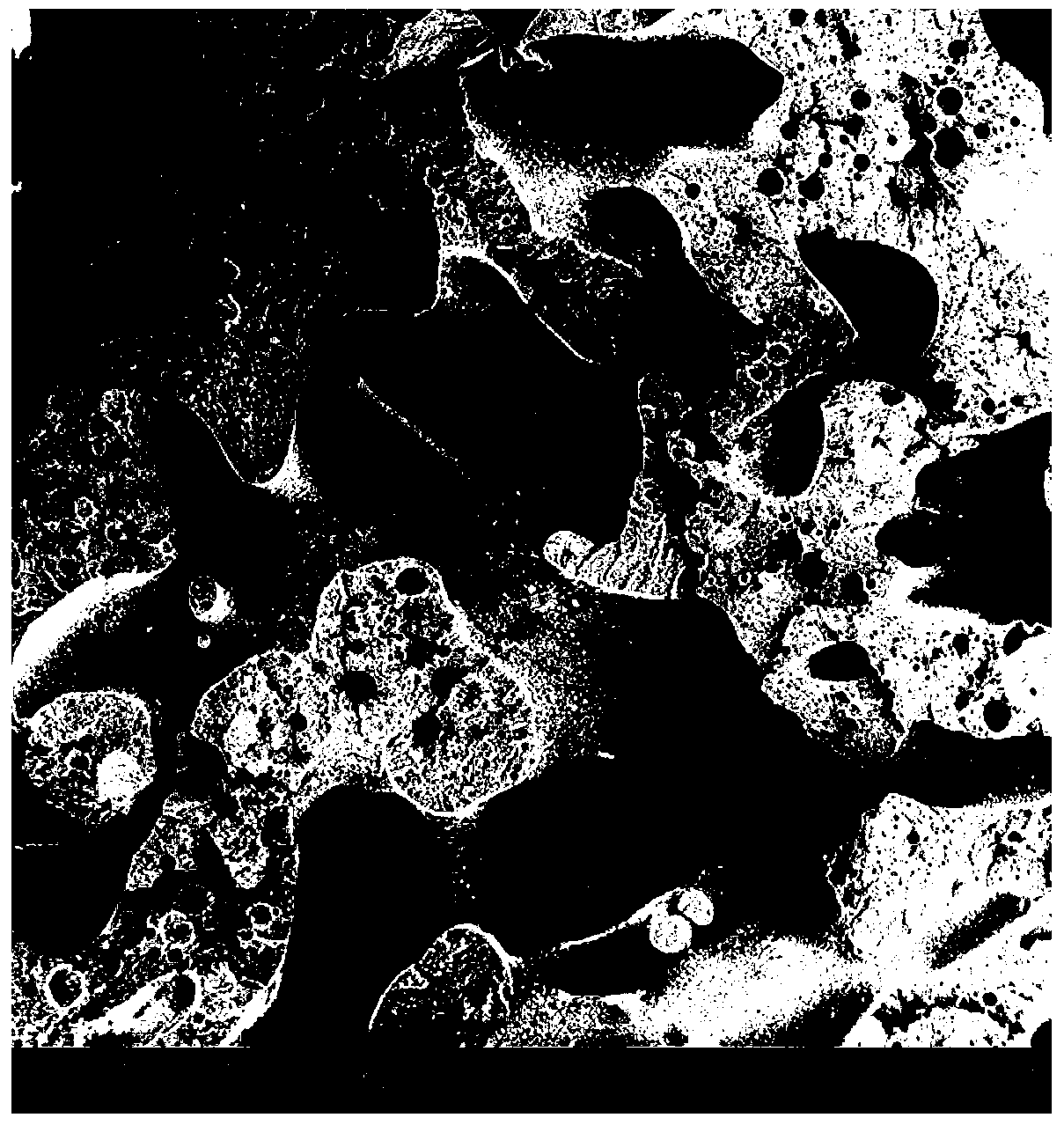

Image

Examples

Embodiment 1

[0026] (1) Weigh two kinds of polymers according to the volume ratio of polylactic acid (PLA): polyvinylpyrrolidone (PVP) = 50: 50, premix the two kinds of polymers at room temperature to obtain a premix, and then premix the The mixture was mixed in a micro extruder at 180°C under normal pressure for 8 minutes at a speed of 80rpm to obtain a melt blend of the two polymers;

[0027] (2) Mold the molten blend obtained in step (1) on a vacuum molding machine, and rapidly cool and shape it to obtain a PLA / PVP flake blend green body. The molding temperature is 180° C., and the molding pressure is 10 MPa , molding time is 5min;

[0028] (3) Place the flake-shaped blended body obtained in step (2) in a high-pressure reactor, feed foaming gas carbon dioxide and raise the temperature to 150°C and pressurize to 20MPa (under this condition, the carbon dioxide has transformed into a supercritical fluid ) heat preservation and pressure for 4 hours to coarsen the flake blended body, and ma...

Embodiment 2

[0031] (1) Weigh two kinds of polymers according to the volume ratio of polylactic acid (PLA):polycaprolactone (PCL)=50:50, and pre-mix the two kinds of polymers at room temperature to obtain a premix, and then premix The mixture was mixed for 5 minutes at 50 rpm in a micro extruder at normal pressure and 180° C. to obtain a melt blend of the two polymers;

[0032] (2) Mold the molten blend obtained in step (1) on a vacuum molding machine, and rapidly cool and shape it to obtain a PLA / PCL flake blend body. The molding temperature is 180° C., and the molding pressure is 10 MPa , molding time is 3min;

[0033](3) Place the sheet-like blend green body obtained in step (2) in a high-pressure reactor, introduce foaming gas carbon dioxide and raise the temperature to 120°C and pressurize to 20MPa (under this condition, the carbon dioxide has transformed into supercritical Fluid) heat preservation and pressure for 1h to coarsen the flake blend body, then heat preservation and pressu...

Embodiment 3

[0036] (1) Weigh the two polymers according to the volume ratio of polylactic-co-glycolic acid (PLGA): polyethylene glycol (PEG) = 60: 40, and pre-mix the two polymers at room temperature to obtain a pre-mixed Then the premix was mixed at normal pressure and 140°C in a micro extruder at a speed of 80rpm for 8min to obtain a melt blend of the two polymers;

[0037] (2) Mold the molten blend obtained in step (1) on a vacuum molding machine, and rapidly cool and shape it to obtain a PLGA / PEG flake blend green body. The molding temperature is 140° C., and the molding pressure is 10 MPa , molding time is 3min;

[0038] (3) Place the sheet-like blend green body obtained in step (2) in a high-pressure reactor, introduce foaming gas carbon dioxide, heat up to 100°C, and pressurize to 20MPa (under this condition, the carbon dioxide has transformed into supercritical Fluid) heat preservation and pressure for 2 hours to coarsen the flake blend body, then heat preservation and pressure f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com