A kind of bamboo activated carbon with controllable pore size and preparation method thereof

An activated carbon and bamboo technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of strong adsorption capacity, high reaction temperature, uncontrollable pore size, etc., and achieve uniform pore size, lower reaction temperature, and effective pore size. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

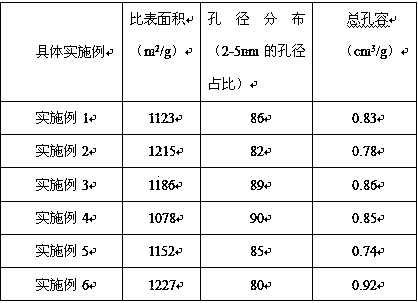

Examples

Embodiment 1

[0028] A bamboo activated carbon with controllable pore size and a preparation method thereof, the specific process of preparing the bamboo activated carbon is as follows:

[0029]First, add 100kg of natural bamboo chips with a moisture content of 15% to 20% into the ultra-fine bamboo powder machine, adjust the bolt of the fineness analyzer in the body to 50 mesh, and then turn on the bamboo powder machine to obtain micronization. Processed bamboo powder. Then add the fine bamboo powder and 10kg chitosan gel into the mixer, set the rotating speed as 60r / min, and the temperature as 60°C, and discharge after mixing for 3.5 hours, so that the chitosan gel is uniformly dispersed in the bamboo powder. Then together with 8kg of citric acid, set the speed of the fast blade to 42r / min, the speed of the slow blade to 35r / min, and the kneading temperature to 80°C, use citric acid to plasticize the inside of the bamboo, so that the bamboo powder has a certain plasticity; knead for 3h F...

Embodiment 2

[0032] A bamboo activated carbon with controllable pore size and a preparation method thereof, the specific process of preparing the bamboo activated carbon is as follows:

[0033] First, add 100kg of natural bamboo chips with a moisture content of 15% to 20% into the ultra-fine bamboo powder machine, adjust the bolt of the fineness analyzer in the body to 40 mesh, and then turn on the bamboo powder machine to obtain micronization. Processed bamboo powder. Then add the fine bamboo powder and 15kg chitosan gel into the kneader, set the rotating speed as 60r / min, and the temperature as 80°C, and discharge after kneading for 2.5h, so that the chitosan gel is uniformly dispersed in the bamboo powder. Then, together with 6kg of citric acid, set the speed of the fast blade to 50r / min, the speed of the slow blade to 28r / min, and the kneading temperature to 70°C, use citric acid to plasticize the inside of the bamboo, so that the bamboo powder has a certain plasticity; knead for 2h ...

Embodiment 3

[0036] A bamboo activated carbon with controllable pore size and a preparation method thereof, the specific process of preparing the bamboo activated carbon is as follows:

[0037] First, add 100kg of natural bamboo chips with a moisture content of 15% to 20% into the ultra-fine bamboo powder machine, adjust the bolt of the fineness analyzer in the body to 60 mesh, and then turn on the bamboo powder machine to obtain micronization. Processed bamboo powder. Then add the fine bamboo powder and 18kg chitosan gel into the mixer, set the rotating speed to 50r / min, and the temperature is 80°C, and discharge after mixing for 3 hours, so that the chitosan gel is evenly dispersed in the bamboo powder middle. Then together with 5kg citric acid, set the fast paddle speed to be 42r / min, the slow paddle speed to be 28r / min, and the kneading temperature to be 80°C, use citric acid to plasticize the inside of the bamboo, so that the bamboo powder has a certain plasticity; kneading 2.5 Afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com