Graphene/carbon nanotube hybrid polymer composite material

A technology of composite materials and carbon nanotubes, applied in the direction of conductive coatings, other chemical processes, chemical instruments and methods, etc., can solve the problems of carbon nanotube dispersion and high cost, and achieve the effect of simple and easy methods and avoiding dispersion work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

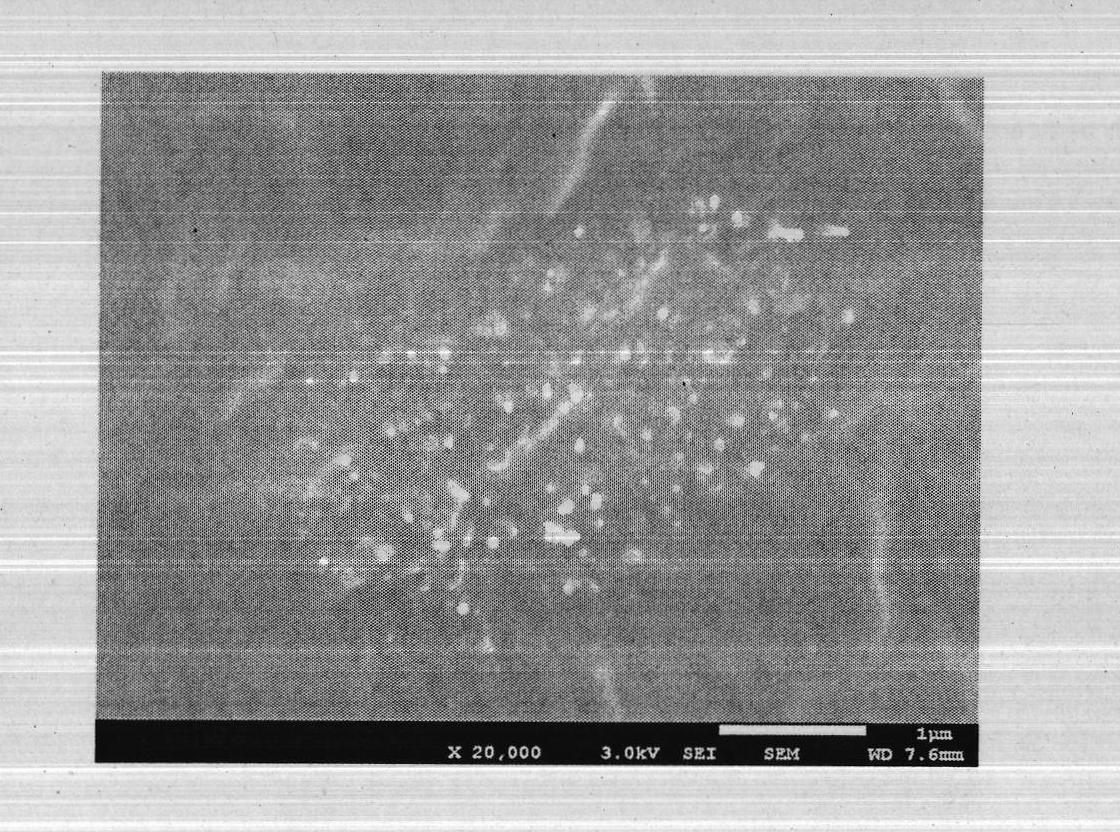

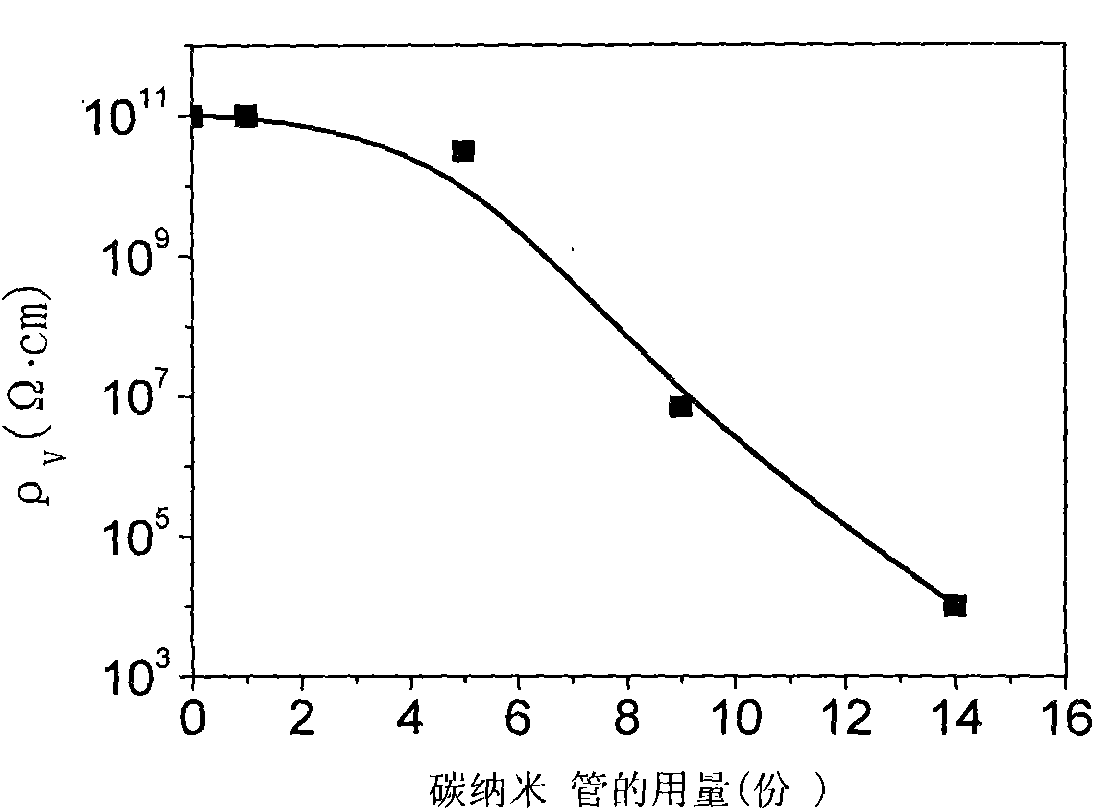

[0016] Take butadiene rubber as an example. Graphene, carbon nanotubes and butadiene rubber were mixed in an internal mixer for 10 minutes according to the weight ratio of 1:9:100, and the obtained composite material was vulcanized at 160° C. for 10 minutes to obtain a graphene / carbon nanotube / butadiene rubber composite Material. The volume resistivity of the material is 7×10 6 Ω·cm, the tensile strength is 3MPa, and the tear strength is 18KN / m.

Embodiment 2

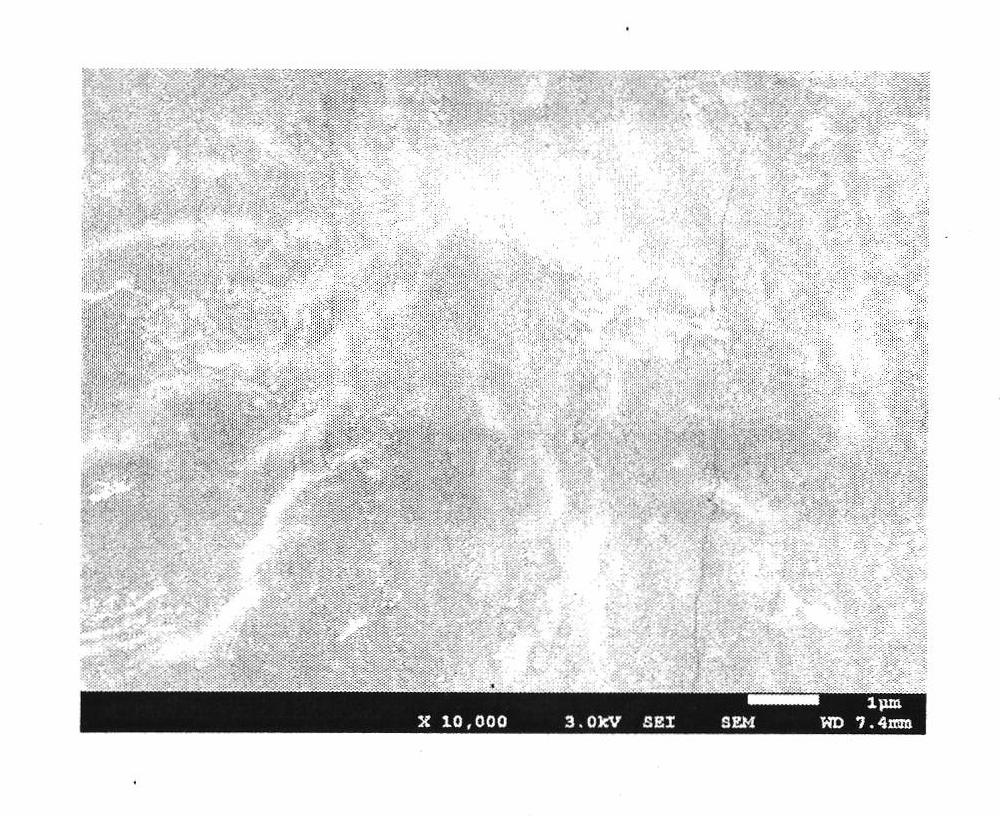

[0018] Take silicone rubber as an example. Silicone rubber 100g is dissolved in 500ml of tetrahydrofuran (THF), graphene and carbon nanotubes are dispersed in 100ml THF by ultrasonic according to the weight ratio of graphene and carbon nanotubes, and the total weight of 3g is then mixed evenly in the air and Excess THF was removed in a vacuum oven. The obtained composite material was vulcanized at 160° C. for 10 minutes to obtain a graphene / carbon nanotube / silicone rubber composite material. The volume resistivity of the material is 4.9×10 9 Ω·cm, the tensile strength is 1MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com