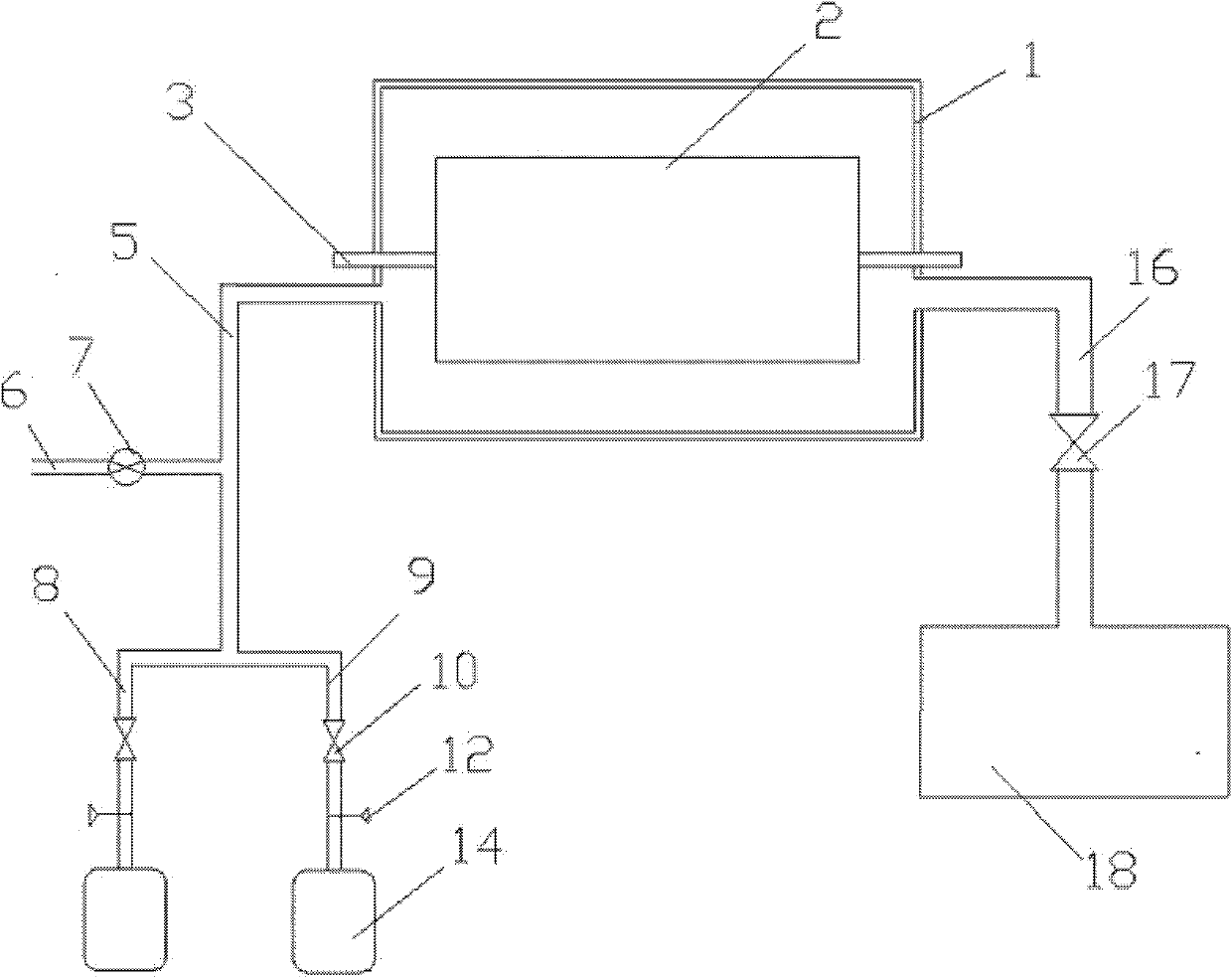

Micronano-scale powder protective layer wrapping device and method

A micro-nano-scale, protective layer technology, applied in coatings, metal material coating processes, gaseous chemical plating, etc., can solve problems such as contact with the surface of powder particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Using the above-mentioned device, the micro-nano-scale powder protective layer wrapping device is used as follows:

[0038] Open the external cavity, take out the internal powder reaction device, put the powder to be wrapped and seal the external cavity. Turn on the vacuum pump, open the vacuum opening valve to connect the vacuum chamber with the vacuum pump, and enter the next step when the vacuum reaches the required vacuum degree (less than or equal to 1 pa);

[0039] Set the temperature of the reaction chamber system, equipment piping, and other components. Set the internal temperature of the reaction chamber system to 200°C, set the temperature of the pipeline to 120°C, and the temperature of the pulse actuator to 130°C. When the displayed temperature is consistent with the set Enter the next step when the temperature is the same and stable (the fluctuation range is less than or equal to 1°C);

[0040] Open the manual sealing valve of the precursor cylinder and se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com