An ultra-thin high-voltage resistant metallized film evaporation equipment

A technology of metallized thin film and high pressure resistance, which is applied in vacuum evaporation coating, metal material coating process, sputtering coating, etc., and can solve the problem of insufficient uniformity of coating thickness of metallized thin film products, and uniform structure and texture of metal wires Problems such as linearity error and wire feed rate deviation of wire feed wheel can be solved to improve the thickness control level, reduce the overall thickness requirement, and improve the pressure resistance and ultra-thin performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The content of the present invention will be described below in conjunction with specific embodiments.

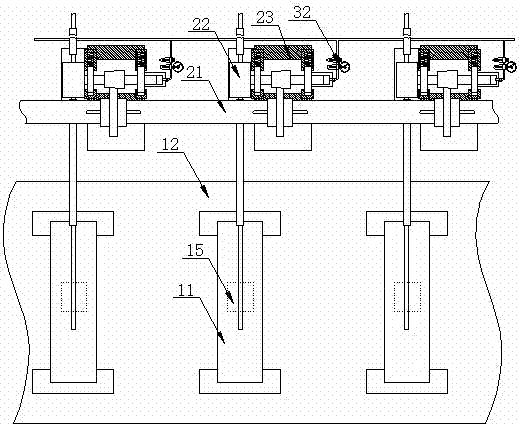

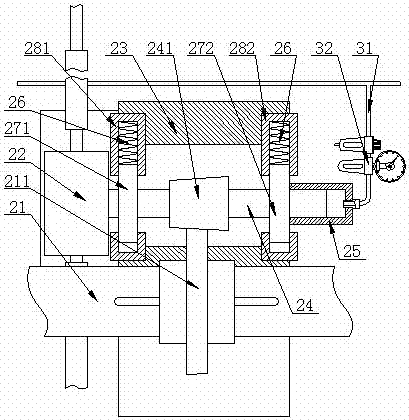

[0027] Such as Figure 1 to Figure 4 As shown, it is a schematic structural diagram of an ultra-thin high-voltage metallized film evaporation equipment according to the present invention. An ultra-thin high-voltage resistant metallized film evaporation device described in the present invention comprises:

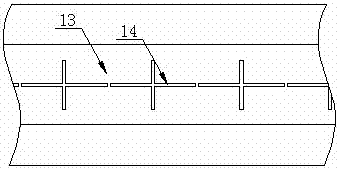

[0028] An evaporation mechanism for heating and evaporating metals. The evaporation mechanism includes several evaporation boats 11; the evaporation mechanism also includes an evaporation furnace 12 and an evaporation spray plate 13 arranged above the evaporation furnace 12. And located below the evaporation spray plate 13, the evaporation spray plate 13 is provided with a hollow evaporation spray tank 14, and the bottom of the evaporation furnace 12 is provided with several exhaust ports 15, several exhaust ports 15 and several evaporation boats 11 One to one co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com