Device and method for preparing diamond film with electric deflection function

A technology of diamond film and preparation device, applied in metal material coating process, gaseous chemical plating, coating and other directions, can solve the problems of limited quality and speed of diamond film preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

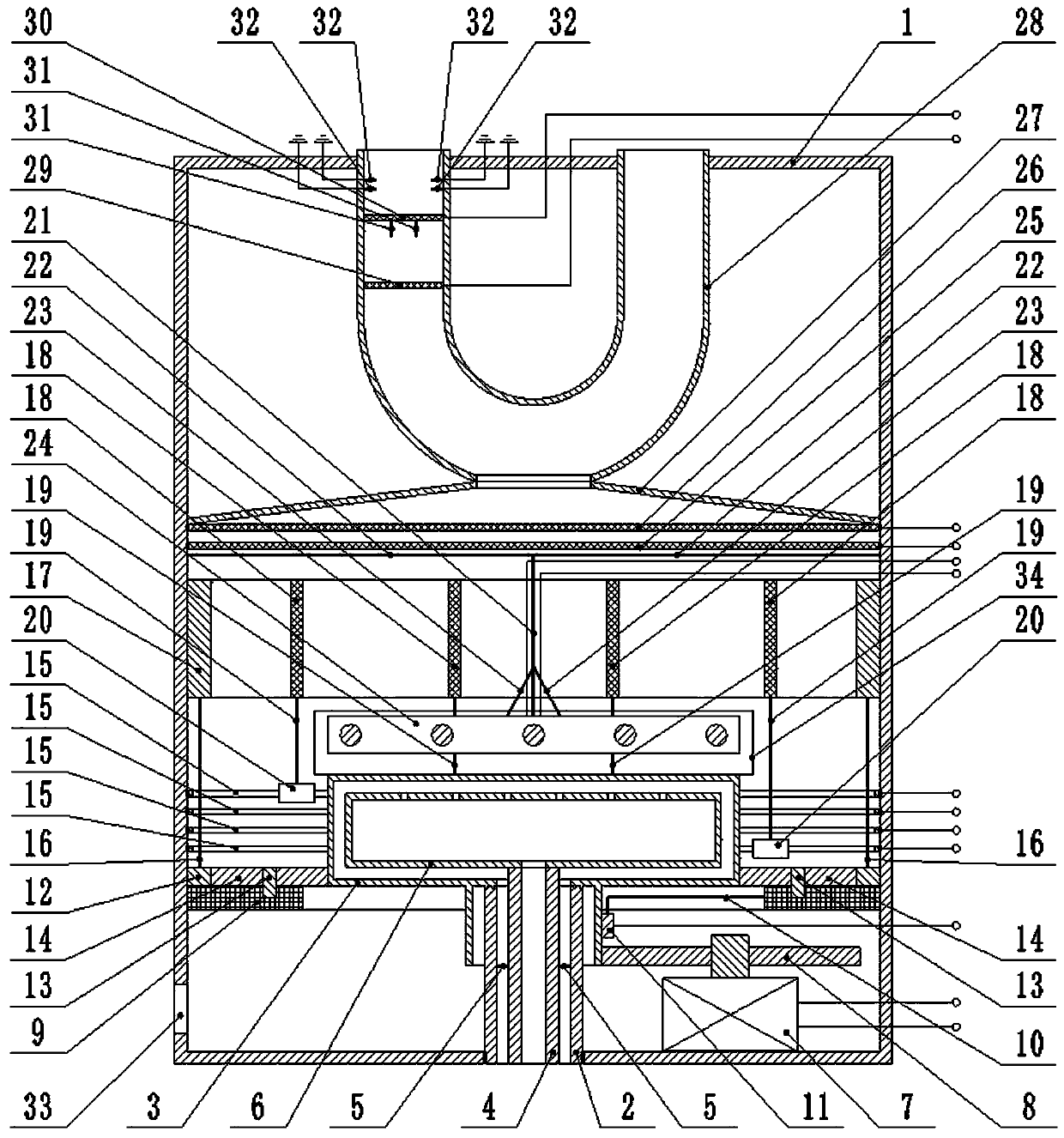

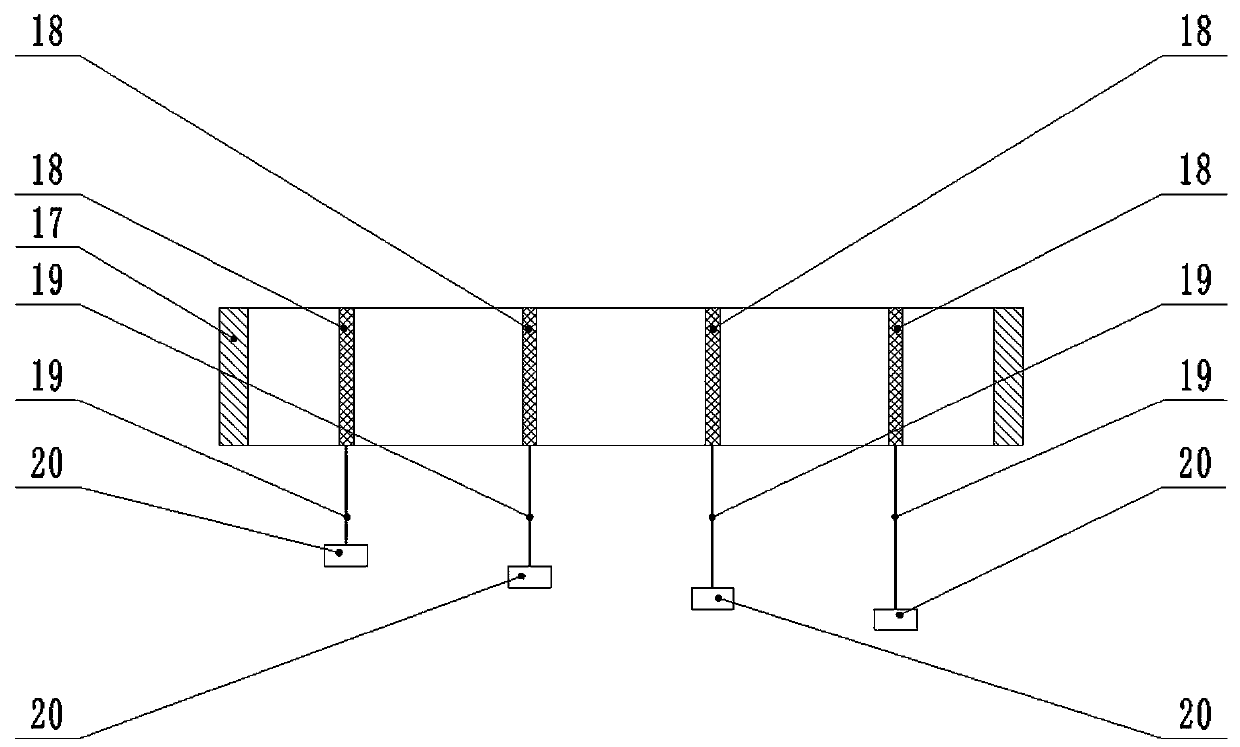

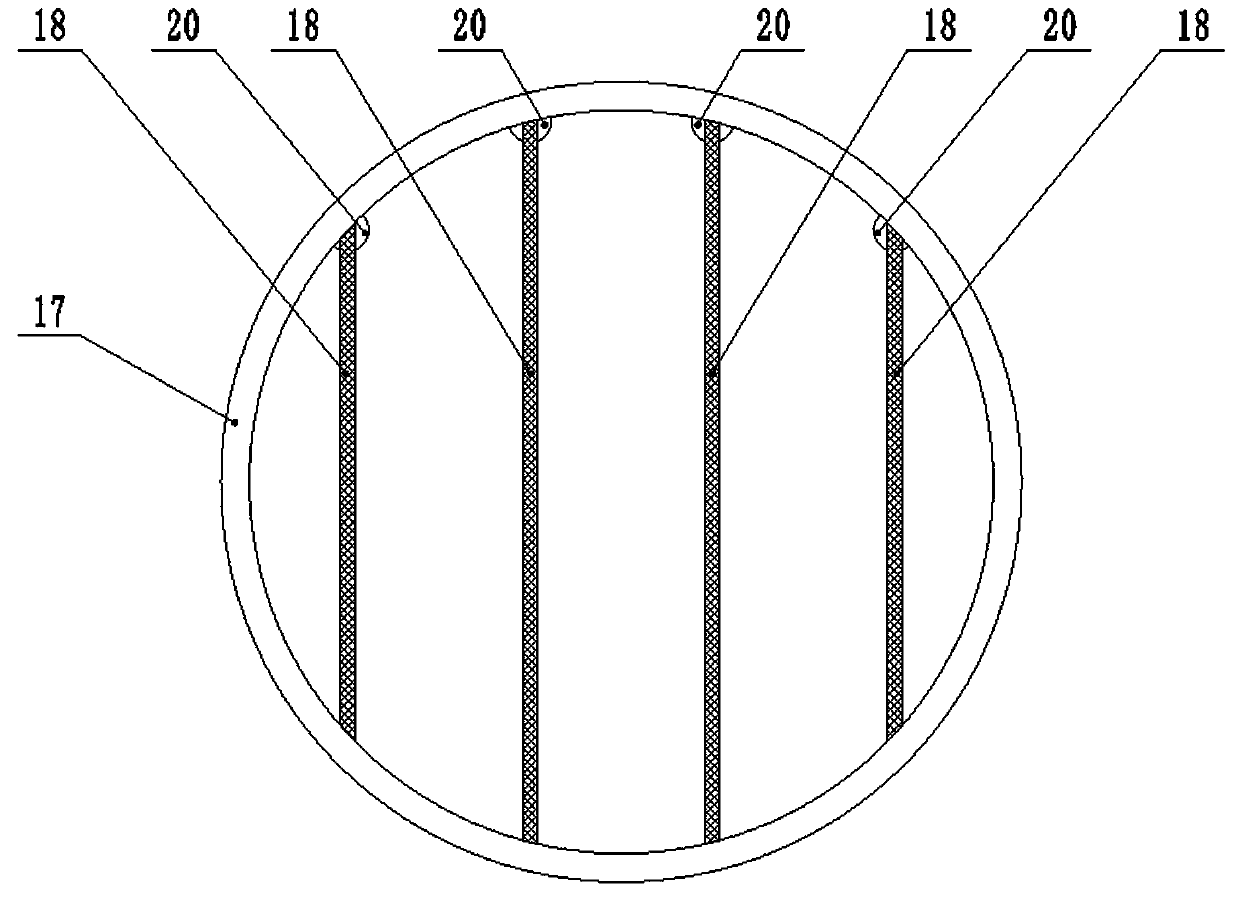

[0022] A diamond film preparation device with electric deflection, comprising a cylindrical reaction chamber 1, an outer water pipe 2, a disc-shaped carrier 3, an inner water pipe 4, radial support rods 5, a disc-shaped water cooling chamber 6, Drive motor 7, drive gear 8, circular supporting plate 9, L-shaped support rod 10, conductive contact 11, transmission ring 12, wheel shaft 13, transmission gear 14, collector ring 15, transmission rod 16, cylindrical Mounting seat 17, rectangular conductive grid 18, conductive rod 19, electric brush 20, vertical mounting rod 21, radial mounting rod 22, inclined rod 23, hot wire array 24, lower circular large conductive grid 25, upper circle Shaped large conductive grid 26, trumpet-shaped air guide cover 27, U-shaped air guide pipe 28, lower circular small conductive grid 29, upper circular small conductive grid 30, discharge needle 31, grounding needle 32, air extraction hole 33, Rectangular window 34, first to tenth power supply;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com