Pumping equipment and distribution hydraulic system and heating method thereof

A hydraulic system and pumping equipment technology, applied in the field of viscous material pumping equipment, can solve the problems of high price, hydraulic oil storage, troublesome handling, troublesome operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

[0032] In pumping equipment, the distribution hydraulic system controls and drives the action of the distribution valve. There are many types of distribution valves, such as S-shaped pendulum valves, C-shaped valves, and inclined gate valves. At present, in the pumping equipment, since the distribution valve operates for a very short time, but the operation speed is very fast, it needs to maintain pressure after the operation. The distribution hydraulic system of the pumping equipment generally adopts a pressure maintaining circuit with an accumulator. There are two commonly used pressure-holding circuits in the distribution system, that is, the pressure-holding circuit using constant-pressure pumps and the pressure-holding circuit using constant-pressure pumps.

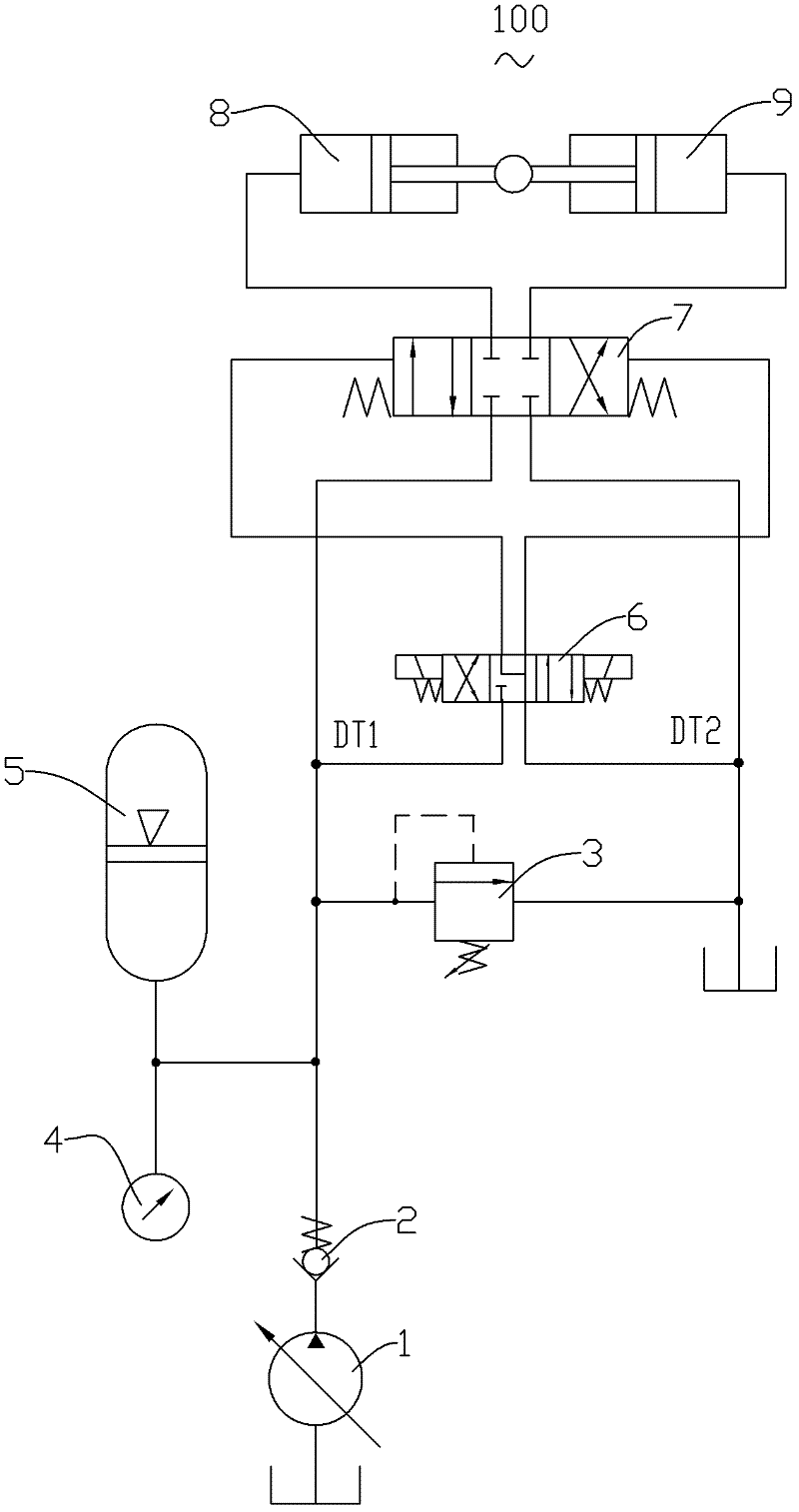

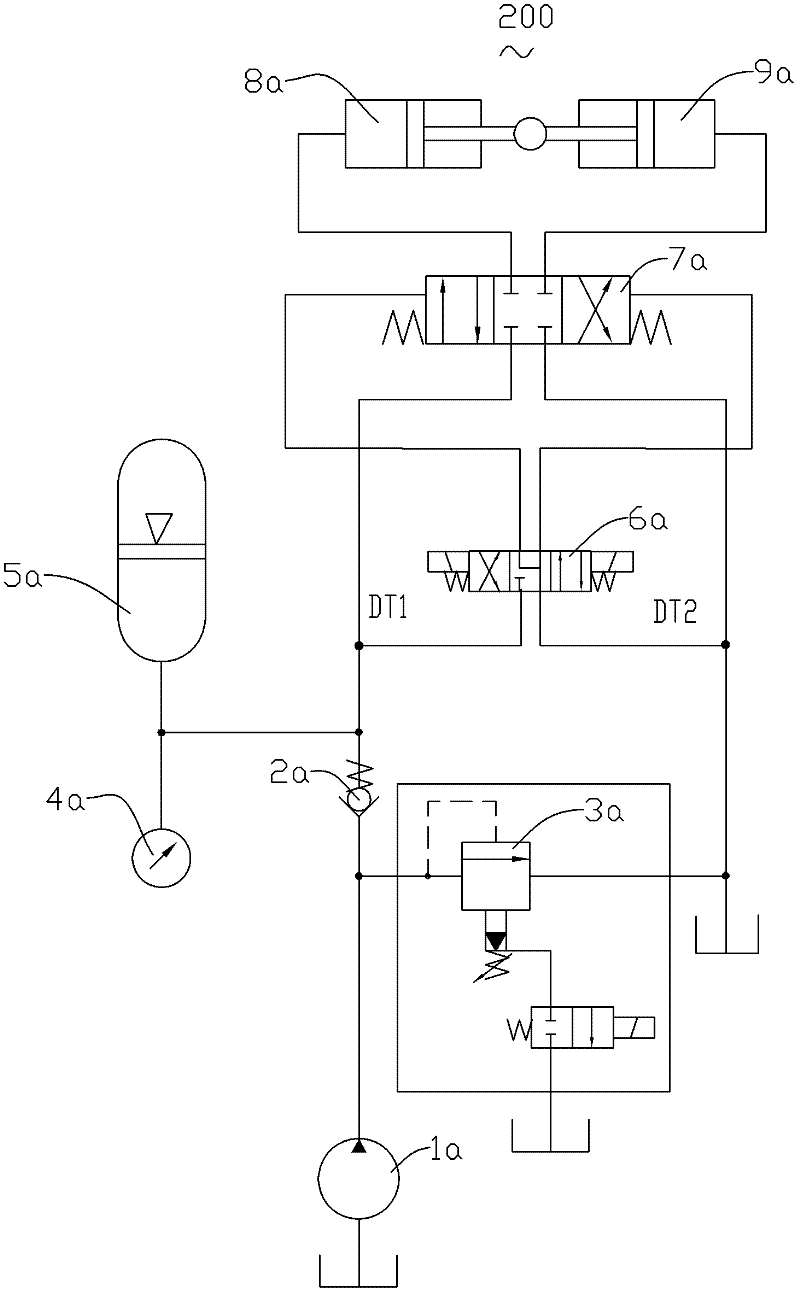

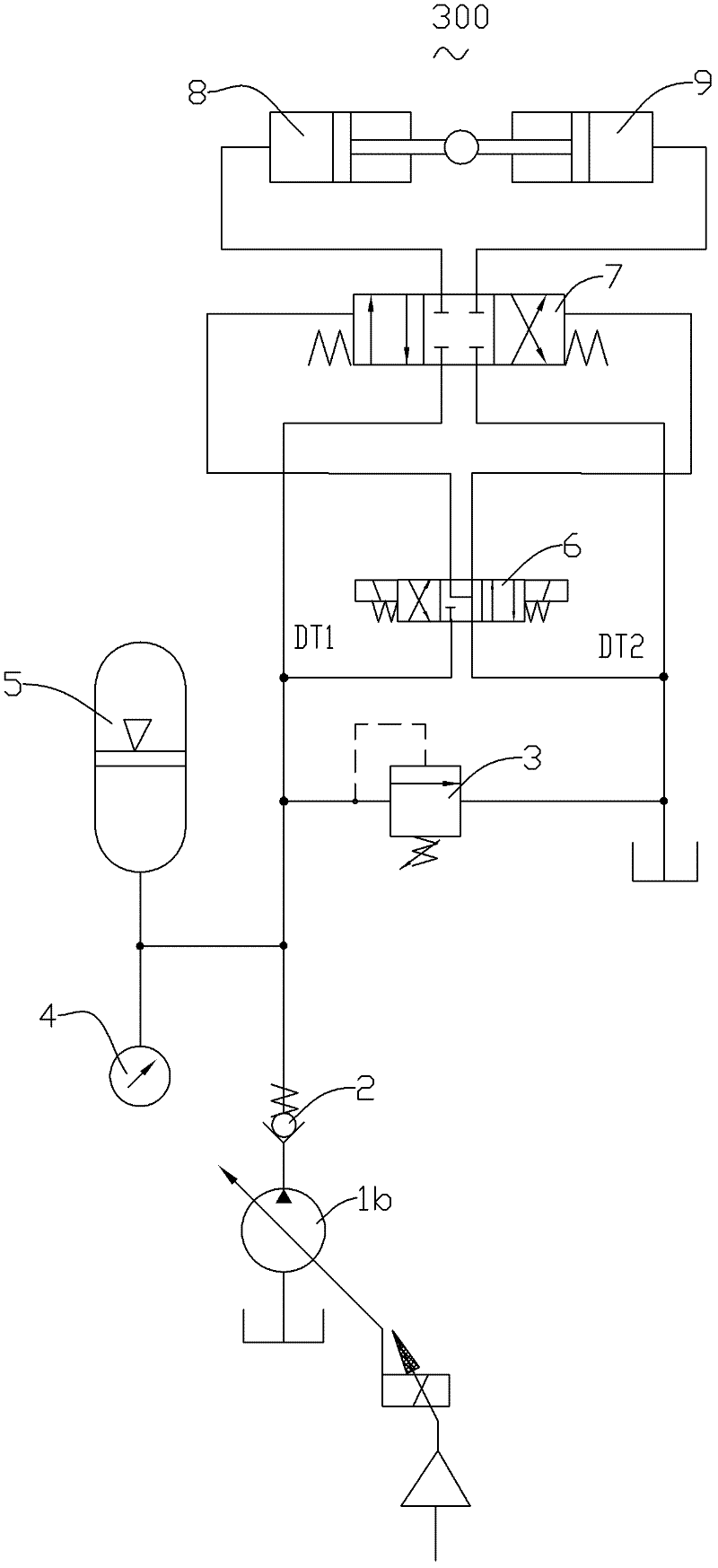

[0033] figure 1 It is a schematic diagram of a distribution hydraulic syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com