Processing procedure for reducing well-edge proximity effect by using curing action of photoresist

A technology of well proximity effect and curing effect, which is applied in the field of microelectronics, can solve the problem of layout area reduction and achieve the effect of increasing physical barrier and reducing WPE effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0017] Such as Figure 2a As shown in -f, the present invention provides a process for reducing the well proximity effect by curing the photoresist, comprising the following steps:

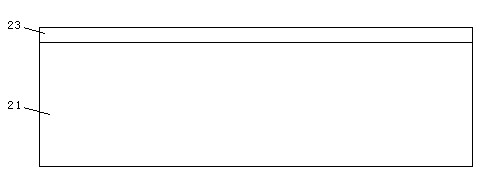

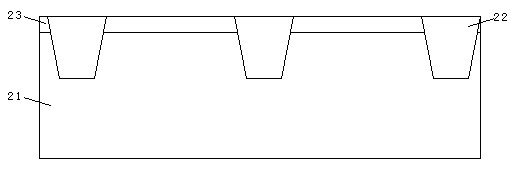

[0018] On the silicon substrate 21, an oxide layer 23 is formed by using a conventional thermal oxidation process as a barrier layer during ion implantation, wherein the thickness of the oxide layer 23 is 80-100 Å; several well regions 22 are embedded in the oxide layer 23 and the silicon substrate 21, and then dazzle the photoresist on the oxide layer 23 and the well region 22, and expose and develop the photoresist to form the photoresist 24 of the mask pattern. Wherein, the well region 22 is an N-type well, a P-type well or a deep N-type buried layer.

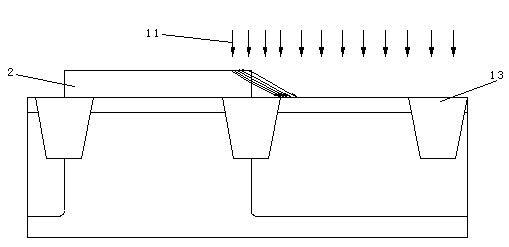

[0019] Further, the photoresist 24 is irradiated with UV 3 to form the shell 24 by using an ultraviolet curing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com