Manufacturing method of TFT (Thin Film Transistor) array substrate and TFT array substrate

The technology of an array substrate and a manufacturing method, which is applied in the field of liquid crystal display, can solve the problems of increasing the storage capacitor area, reducing the aperture ratio of pixels, and being easily affected by strong light, so as to increase the aperture ratio, reduce the area, and avoid stability sex-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

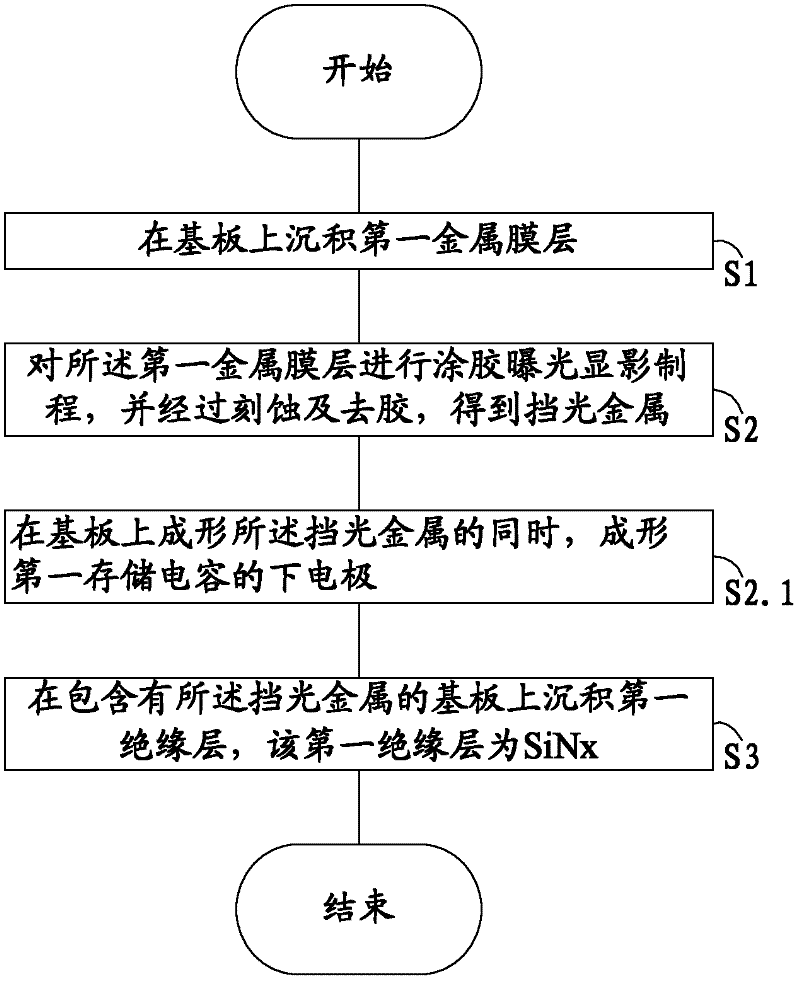

Method used

Image

Examples

no. 1 example

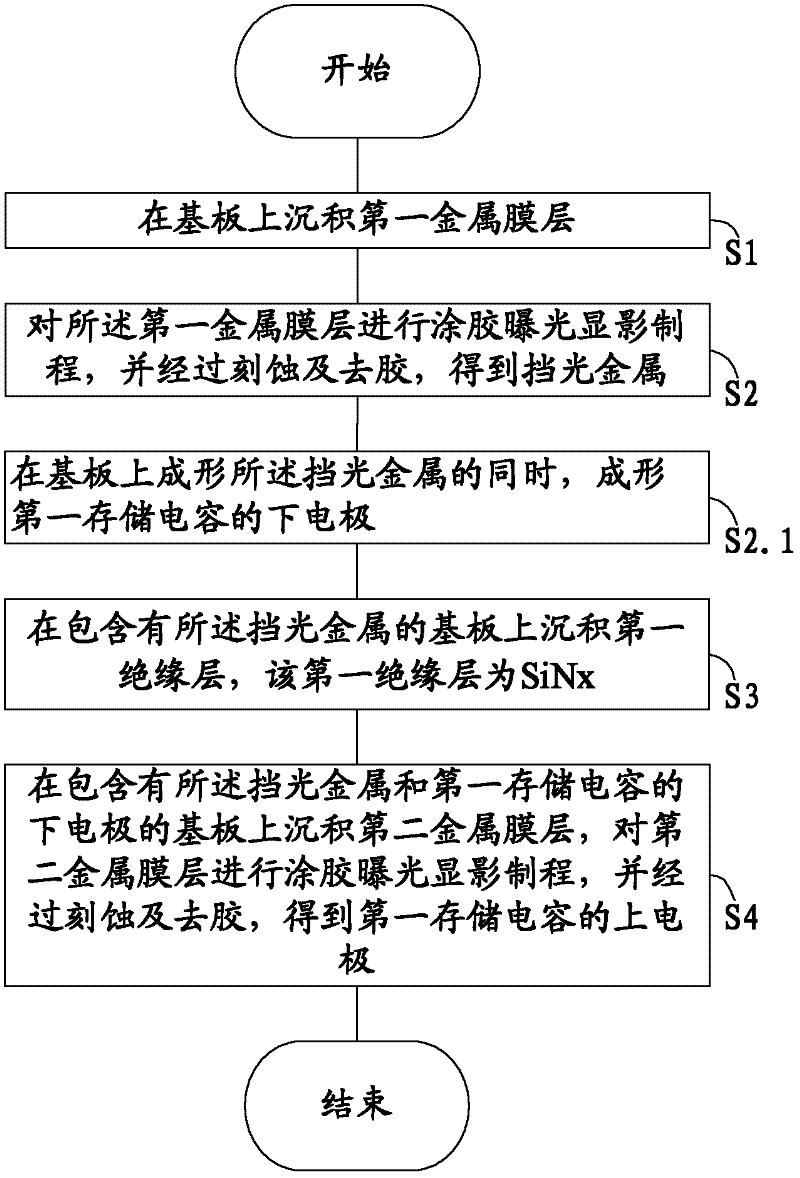

[0042] Compared with the first embodiment, in this embodiment, the manufacturing method of the TFT array substrate may further include:

[0043] Step S4, depositing a second metal film layer on the substrate including the light-blocking metal and the lower electrode of the first storage capacitor, performing a coating, exposure and development process on the second metal film layer, and then etching and removing the glue, Obtain the upper electrode of the first storage capacitor.

[0044]After obtaining the light-blocking metal and the lower electrode of the first storage capacitor, a vacuum sputtering method can be used to deposit a layer on the first insulating layer deposited on the substrate containing the light-blocking metal and the lower electrode of the first storage capacitor. The second metal film layer, then, can adopt the PECVD method to deposit a layer of ohmic contact layer on the second metal film layer, and carry out the process of coating, exposing and develop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com