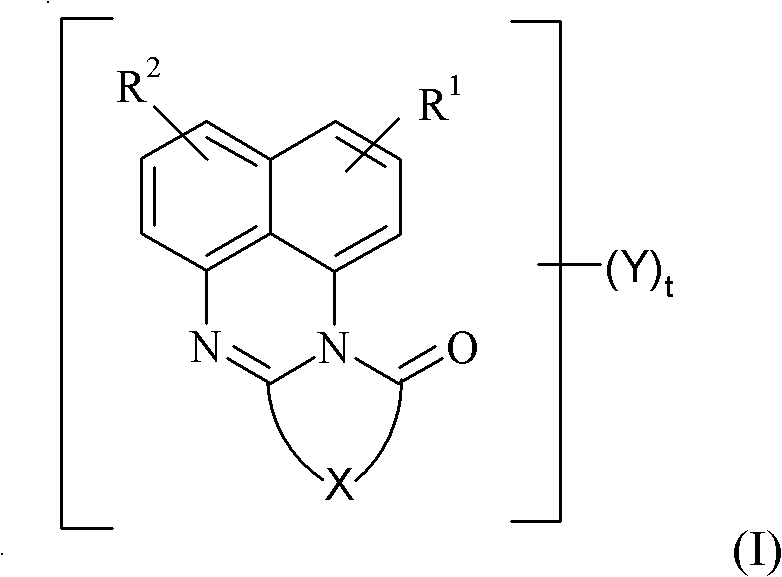

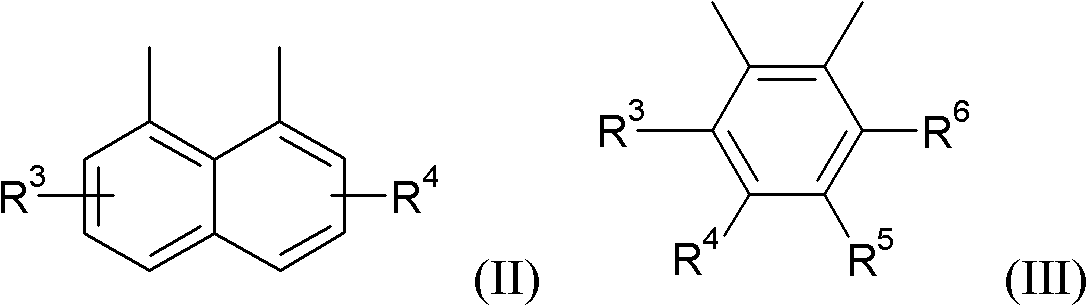

Dyes for polymer coloration, their preparation and their use

A dye, C1-C6 technology, used in dyeing, textiles and papermaking, peri-ketone, etc., can solve problems such as poor light fastness, low thermal stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

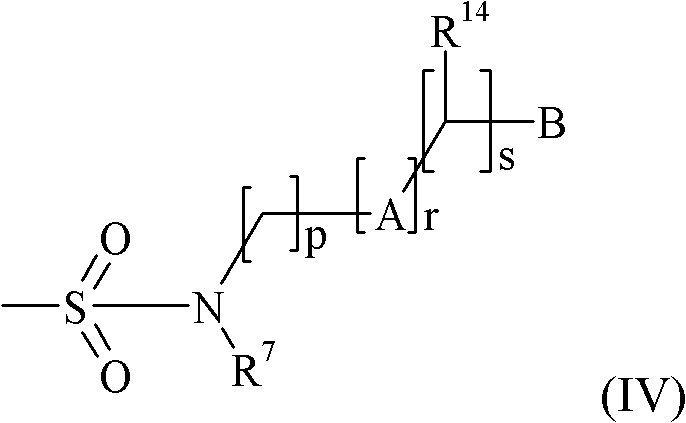

[0216] a) A mixture of 31.4 parts of the compound of formula (IXa) and 93 parts of chlorosulfonic acid was stirred at 60°C for 2 hours. The reaction mixture was cooled, then mixed with 31 parts of thionyl chloride, stirred overnight, and then poured into ice water. The separated precipitate was washed with water to neutrality and dried to obtain 47.5 parts of a dye mixture of formula (VIIa),

[0217]

[0218] Where t is 1 or 2.

[0219] b) A mixture consisting of 80 parts of dioxane aqueous solution, 13.1 parts of hexadecylamine (from Merck KGaA), 4.15 parts of sodium carbonate and 10.74 parts of the compound of formula (VIIa) was stirred at 50°C for 5 hours. After the reaction, the reaction mixture was mixed with methanol. The separated precipitate is purified and dried to obtain 15 parts of a dye mixture of formula (Ig),

[0220]

[0221] Where t is 1 or 2.

[0222] c) 1 g of the dye prepared in step b) is pulverized in a mortar and then added to a total of 2 kg of polypropylene ...

Embodiment 2

[0224] a) A mixture consisting of 80 parts of dioxane aqueous solution, 13.5 parts of octadecylamine (from Chempur Feinchemikalien und Forschungsbedarf GmbH), 4.15 parts of sodium carbonate and 10.70 parts of a compound of formula (VIIa) was stirred and reacted at 50°C for 5 hours. After the reaction, the reaction mixture was mixed with methanol. The separated precipitate is purified and dried to obtain 15.1 parts of a dye mixture of formula (Ih),

[0225]

[0226] Where t is 1 or 2.

[0227] b) 1.28 g of the dye prepared in step a) was pulverized in a mortar and then added to a total of 2 kg of polypropylene pellets (Moplen RP340R from Basell). The mixture was crushed to homogeneity in a rolling mill, then extruded and pelletized in a twin screw extruder (ZSE 18HP-D40 from Leistritz). The pellets obtained can be processed in an injection molding machine (420C 1000-100 from Arburg) to form a transparent orange-red sample substrate. The dye has high bleed fastness (according to p...

Embodiment 3

[0229] a) A mixture of 40 parts of dioxane aqueous solution, 9.3 parts of dodecylamine (from Sigma-Aldrich Inc.), 4.15 parts of sodium carbonate and 10.74 parts of the compound of formula (VIIa) was stirred at 50°C for reaction hour. After the reaction, the reaction mixture was mixed with methanol. The separated precipitate was purified and dried to obtain 6.9 parts of a dye mixture of formula (Ii),

[0230]

[0231] Where t is 1 or 2.

[0232] b) 1 g of the dye prepared in step a) was pulverized in a mortar and then added to a total of 2 kg of polypropylene pellets (Moplen RP340R from Basell). The mixture was crushed to homogeneity in a rolling mill, and then extruded and pelletized in a twin screw extruder (ZSE 18HP-D40 from Leistritz). The obtained pellets can be processed in an injection molding machine (420C 1000-100 from Arburg) to form a transparent orange-red sample substrate. The dye has high bleed fastness (according to prEN14469-4), high heat-resistant color stabilit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com