Porous stent with network passage and preparation method of porous stent

A technology of porous scaffolds and network channels, applied in the field of biomaterials and regenerative medicine, can solve the problem of no difference in effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

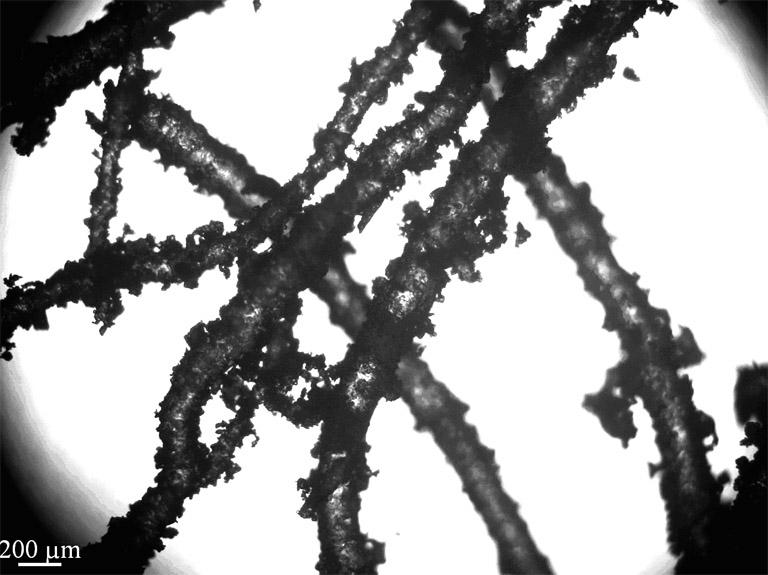

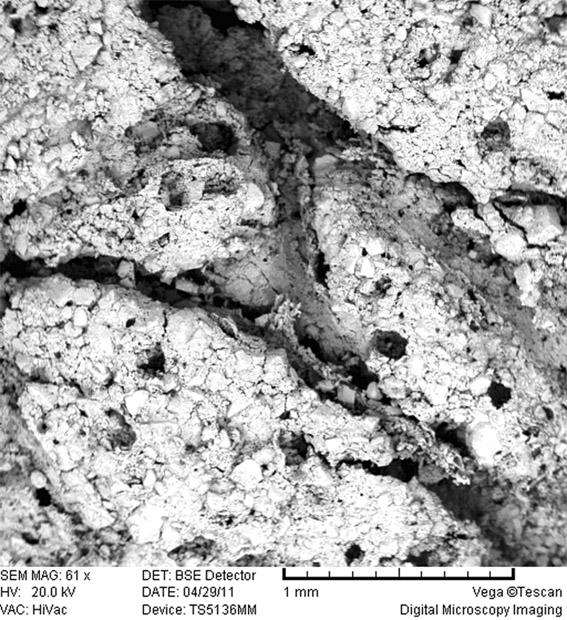

[0035] Example 1 Add 1.8 g β-TCP to 1.1 g 5% polyvinyl alcohol (PVA) aqueous solution, stir, grind, then add 0.45 g 380-550 μm diameter paraffin balls and stir evenly, then pour 0.054 g loofah (diameter 300 μm), the scaffold was taken out, placed at room temperature for 24 h, put into a muffle furnace and heated to 1050 °C for sintering, and a porous scaffold with network channels was obtained. A three-dimensional porous scaffold with channels (300 μm in diameter) with a pore size of about 450 μm and a porosity of about 50% was obtained.

Embodiment 2

[0036] Example 2 Add 1.8 g of hydroxyapatite to 1.1 g of 5% PVA aqueous solution, stir, grind, then add 0.45 g of paraffin balls with a diameter of 380-550 μm and mix well, then pour into a mold with 0.054 g of loofah (300 μm in diameter) After compression molding, the scaffold was taken out, left at room temperature for 48 h, placed in a muffle furnace and heated to 1100 °C for sintering to obtain a three-dimensional porous scaffold with a channel (diameter of 300 μm) with a pore diameter of about 450 μm and a porosity of about 50%.

Embodiment 3

[0037] Example 3 Add 1.8g β-TCP to 0.54 g 10% PVA aqueous solution, stir, grind, then add 0.45 g 270-380 μm diameter paraffin balls and stir evenly, then pour into a mold with 0.054 g loofah (diameter 300 μm) for molding After molding, the scaffold was taken out, left at room temperature for 24 h, put into a muffle furnace and heated to 1050 °C for sintering, and a three-dimensional porous scaffold with a channel (diameter of 300 μm) with a pore diameter of about 300 μm and a porosity of about 50% was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com