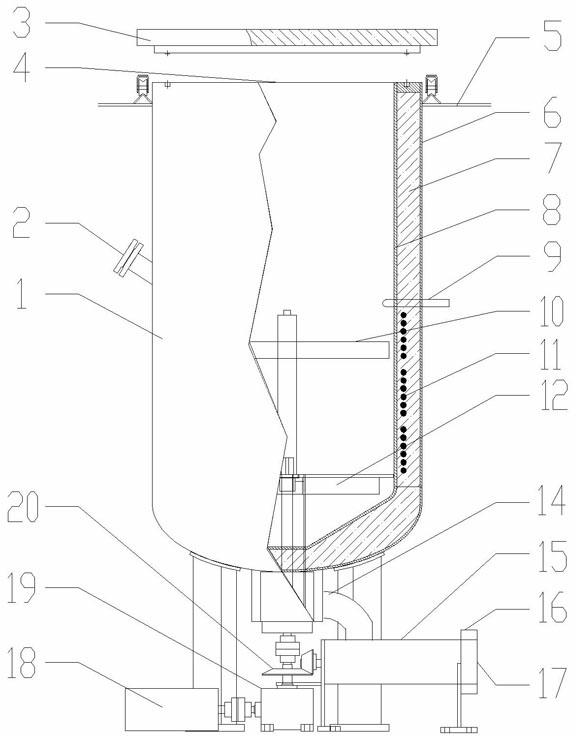

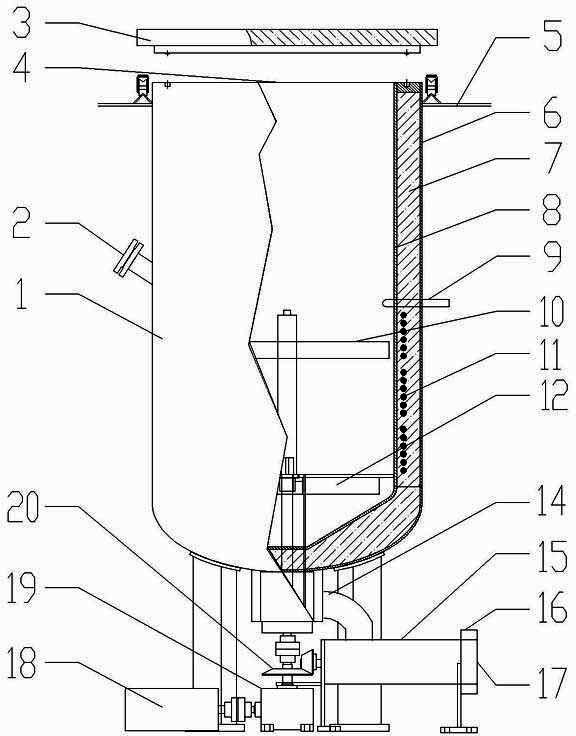

Garbage cracking furnace

A pyrolysis furnace and garbage technology, applied in the direction of solid waste removal, etc., can solve the problems of easy generation of odorous gas, high operation cost, large energy consumption, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] As shown in the figure, the present invention comprises cracking furnace furnace body 1, cover plate 3, electric motor 18, speed changer 19, and described cracking furnace furnace body 1 top opening is feeding port 4, and the rubbish to be processed is dropped into from described feeding port 4 Inside the cracking furnace body 1, the cracking furnace body 1 is used as a sealed container, so that the garbage is cracked at a high temperature inside the cracking furnace body 1, and the cover plate 3 is sealed and fitted with the feeding port 4, and the The upper part of the cracking furnace body 1 is provided with a gas outlet 5, and the gas generated during the high-temperature cracking process of garbage is discharged from the gas outlet 5 and further purified by external equipment. The cracking furnace body 1 includes an inner tank 8, an outer liner 6, the inner liner 8 has high thermal conductivity, and the outer liner 6 has heat insulation protection to prevent operato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com