Two-layer coated water-retaining sustained-release fertilizer and preparation method thereof

A double-coated, slow-release fertilizer technology, applied to fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of high toxicity, loss of fertilizer nutrients, short duration, etc., achieve good water retention and moisture retention, and improve water absorption capacity , the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

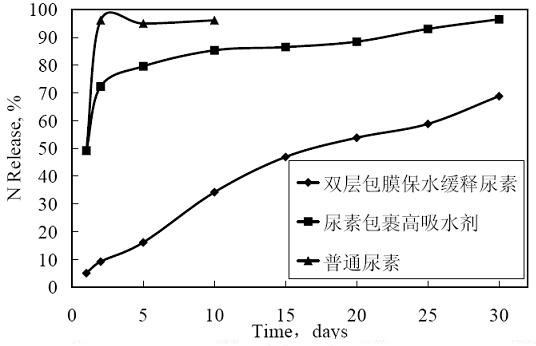

[0029] (1) Preparation of double-coated water-retaining slow-release urea fertilizer

[0030] Put 90 parts of urea granules with a diameter of 1-2 mm in a disc granulator (Zhengzhou Ruiheng Machinery Manufacturing Co., Ltd., ZL10), spray atomized water to wet the surface of urea granules, and pass 10 parts through 110 mesh The sieved carrageenan powder is added to the disc granulator for rolling coating, so that it is wrapped on the fertilizer core, because urea and water produce ammonium ions (NH 4 + ), cross-linked carrageenan. Finally, 10 parts of the prepared water-absorbent resin powder (agricultural superabsorbent resin, NIPPO, Nippon Shokubai) were added to the disc for rolling coating, so that the water-absorbent resin powder was wrapped on the outer layer of the fertilizer particles as the outer coating of the fertilizer. Then, it is dried at room temperature to obtain the finished product of double-coated water-retaining slow-release urea fertilizer.

[0031] ...

Embodiment 2

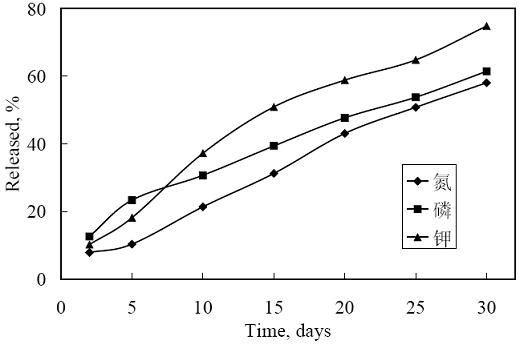

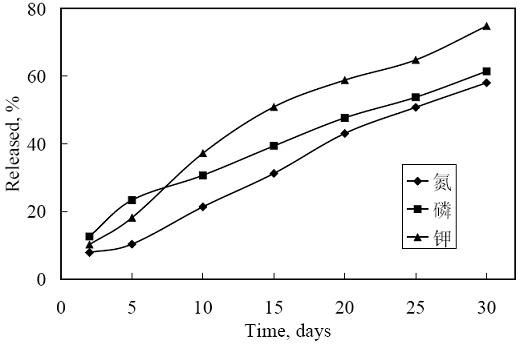

[0045] (1) Preparation of double-layer coated water-retaining slow-release compound fertilizer

[0046] Put 92 parts of nitrogen, phosphorus and potassium compound fertilizer particles (provided by Shandong Xitiantian Ecological Fertilizer Co., Ltd.) with a diameter of 1-2mm in the disc granulator (Zhengzhou Ruiheng Machinery Manufacturing Co., Ltd., ZL10), spray into the mist After the surface of the granule is wetted with water, add 8 parts of carrageenan powder that has passed through a 110 mesh sieve into the disc granulator for rolling coating, so that it is wrapped on the kernel of the fertilizer, and spray 5% KCl aqueous solution on the carrageenan. Carry out cross-linking, consumption is 8% of carrageenan dry weight, cross-linked carrageenan. Finally, 10 parts of the prepared water-absorbent resin powder (agricultural superabsorbent resin, NIPPO, Nippon Shokubai) were added to the disc for rolling coating, so that the water-absorbent resin powder was wrapped on the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com