Serpentine type heat exchanger

A tubular heat exchanger and heat exchange tube technology, applied in the direction of heat exchanger types, indirect heat exchangers, fixed conduit components, etc., can solve the problems of small total heat transfer coefficient K value, etc. Small resistance, good heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

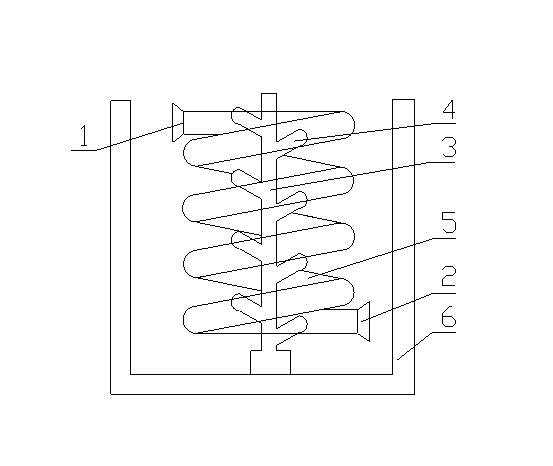

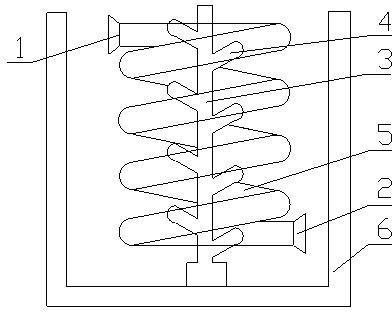

[0015] A serpentine heat exchanger is composed of an inlet pipe 1, an outlet pipe 2, a stirring rod 3, a stirring blade 4, and a serpentine heat exchange pipe 5; the upper end of the serpentine heat exchange pipe 5 is connected to the inlet pipe 1, The lower section is connected to the outlet pipe 2, and the annular space formed inside the serpentine heat exchange tube 5 is nested with the stirring rod 3, and the stirring rod 3 has a stirring blade 4 on it.

[0016] The inlet pipe 1, outlet pipe 2 and serpentine heat exchange pipe 5 are made of carbon fiber composite material.

[0017] The stirring rod 3 and the stirring blade 4 are made of carbon fiber composite material.

[0018] When working, the stirring rod 3 at the bottom of the serpentine heat exchanger immersed in the container 6 rotates, driving the stirring blade 4 to rotate, and the cooling liquid is passed into the inlet pipe 1, and the cooling liquid passes through the inlet pipe 1 and the serpentine heat exchange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com