Automatic temperature regulating method of high-temperature flue gas for metal heat exchanger

A high-temperature flue gas and heat exchanger technology, applied in heat exchange equipment, lighting and heating equipment, etc., can solve problems such as affecting production and safe operation of equipment, local weld cracking, heat exchanger deformation, etc., without daily maintenance. , prolong the service life, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

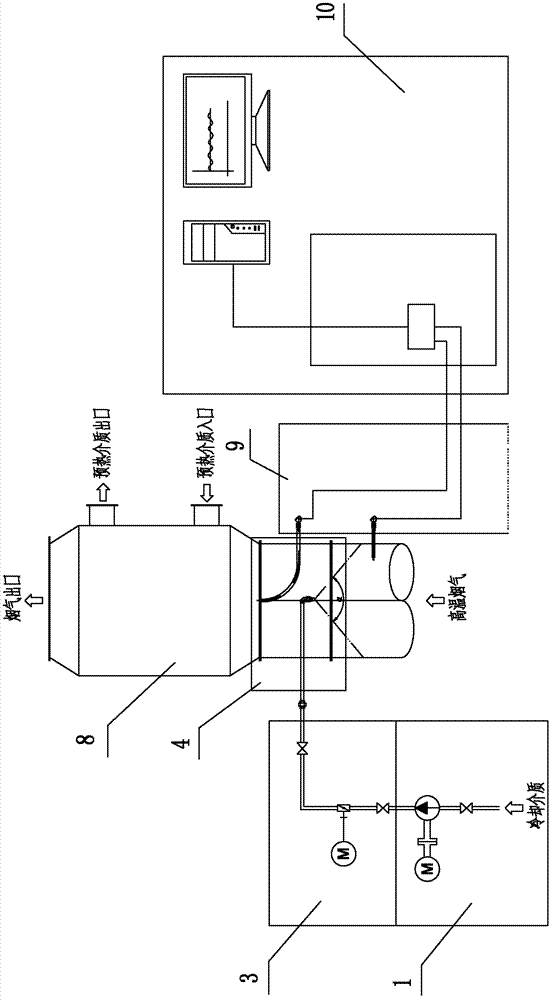

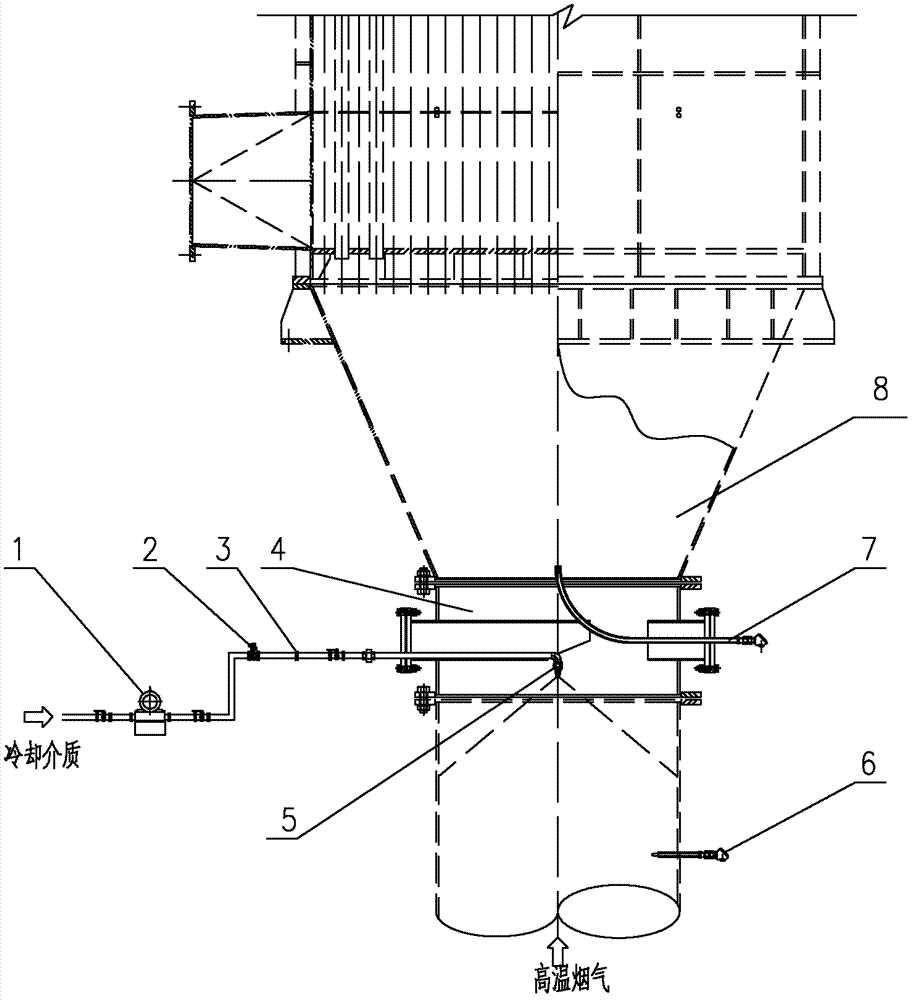

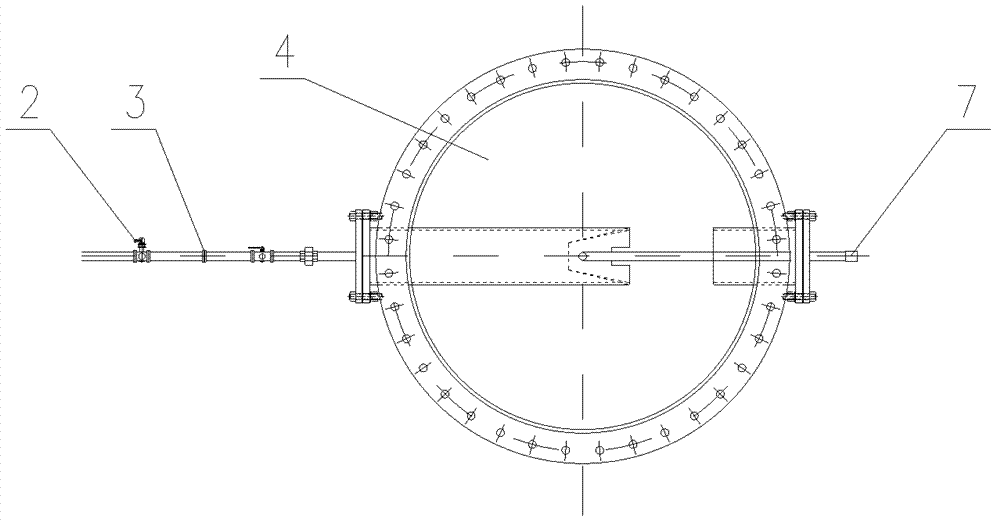

[0018] See Figure 1 ~ Figure 3 , a high-temperature flue gas automatic temperature regulation device for metal heat exchangers, including a cooling medium supply unit 1, an automatic flow control unit 3, an automatic temperature regulation body 4, an atomizing nozzle 5, a temperature detection unit 9 and a logic control unit 10. The cooling medium supply unit 1 is used to send liquid or gaseous cooling medium such as demineralized water and compressed air into the metal heat exchanger through the delivery pipe; the automatic flow control unit 3 is used to detect and automatically control the delivery flow of the cooling medium; the temperature detection unit 9 includes an inlet temperature-measuring thermocouple 6 and an outlet temperature-measuring thermocouple 7, which are respectively used to detect the inlet temperature of high-temperature f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com