Deepwater liquid level exploration cable

A technology for detecting cables and liquid levels, applied in the direction of insulated cables, bendable cables, cables, etc., to achieve the effects of preventing corrosion, good flexibility, and avoiding damage to the sheath

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

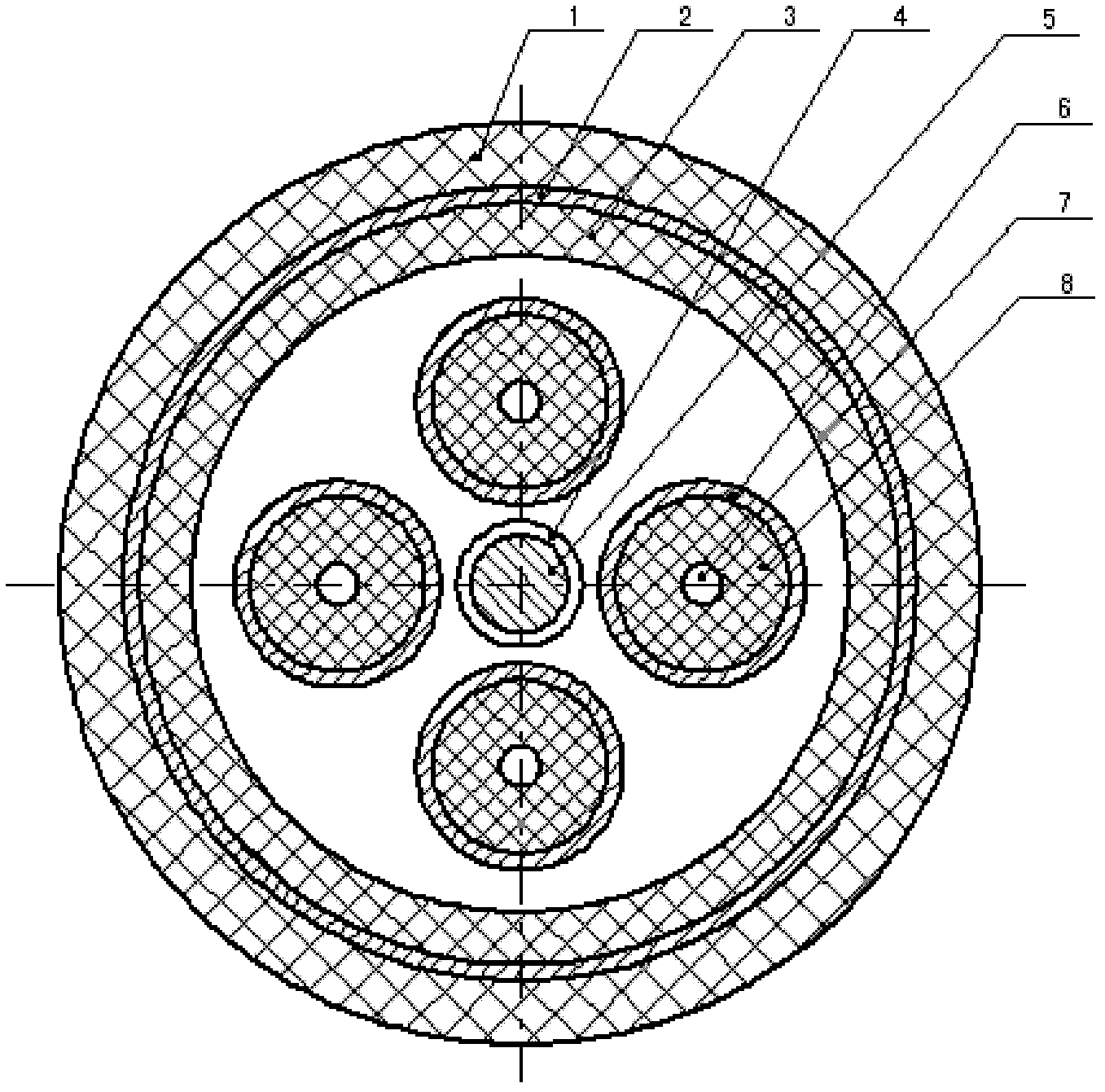

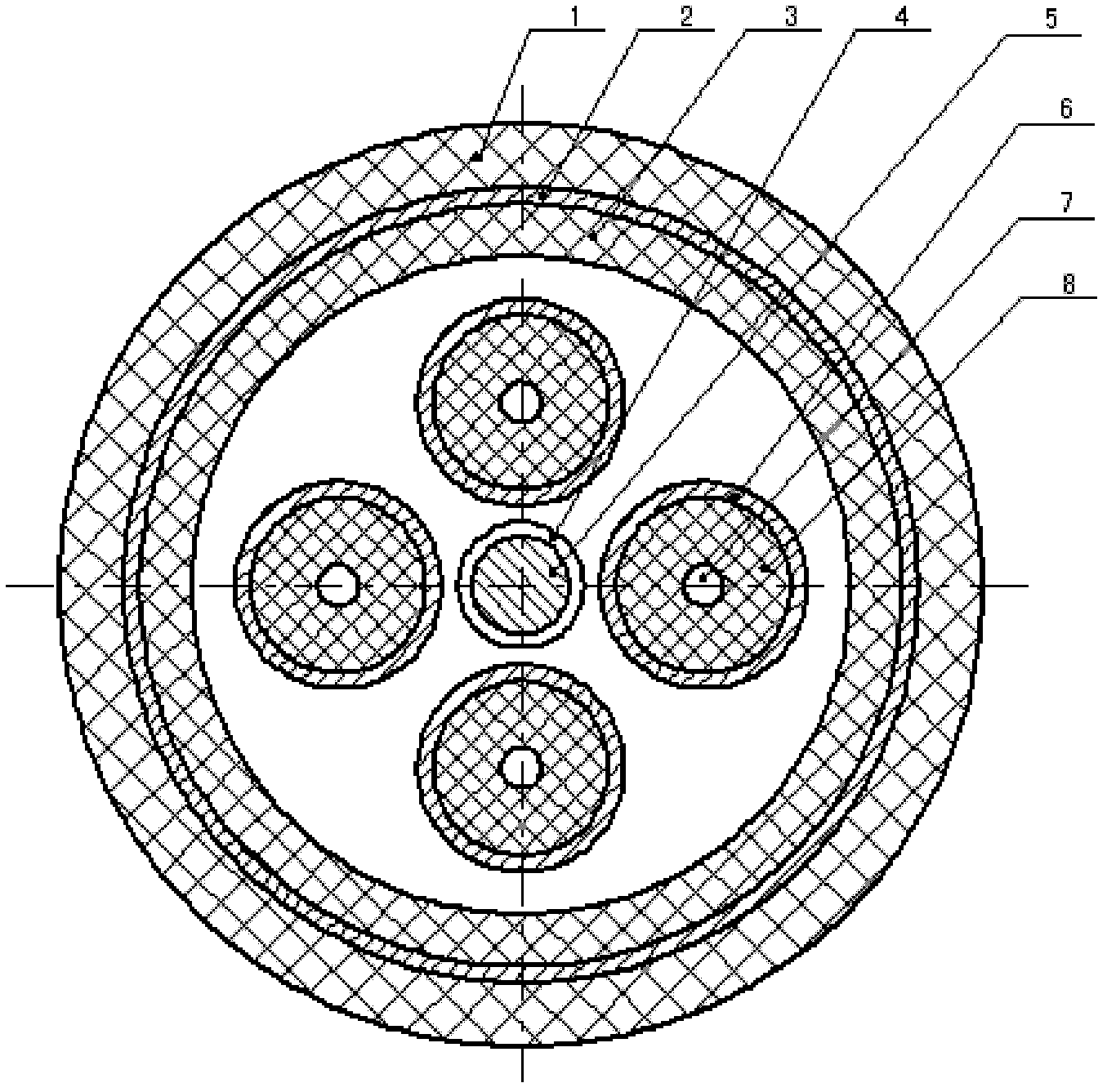

[0016] A deep-water liquid level detection cable, including an outer sheath 1, an inner sheath 3, and an insulated wire core 8, the outer sheath and the inner sheath are coaxially installed, and a plurality of insulated wire cores are evenly distributed in the inner sheath. There are four insulated wire cores in the accompanying drawings, the insulating material of which is polyethylene, and an inner conductor 7 is coaxially installed in the insulated wire cores. The outer sheath is made of thick polyether polyurethane, and the inner sheath is made of polyethylene material with good water resistance.

[0017] The innovation point of the present invention is:

[0018] A steel wire reinforcement core ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com