Preparation method of thin-type backlight notebook computer key structure

A notebook computer and backlight technology, applied in the direction of electrical components, electric switches, circuits, etc., can solve problems such as inability to operate notebook computers effectively, and achieve the goals of enhancing market competitiveness, reducing overall thickness, reducing mold costs and product development cycles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

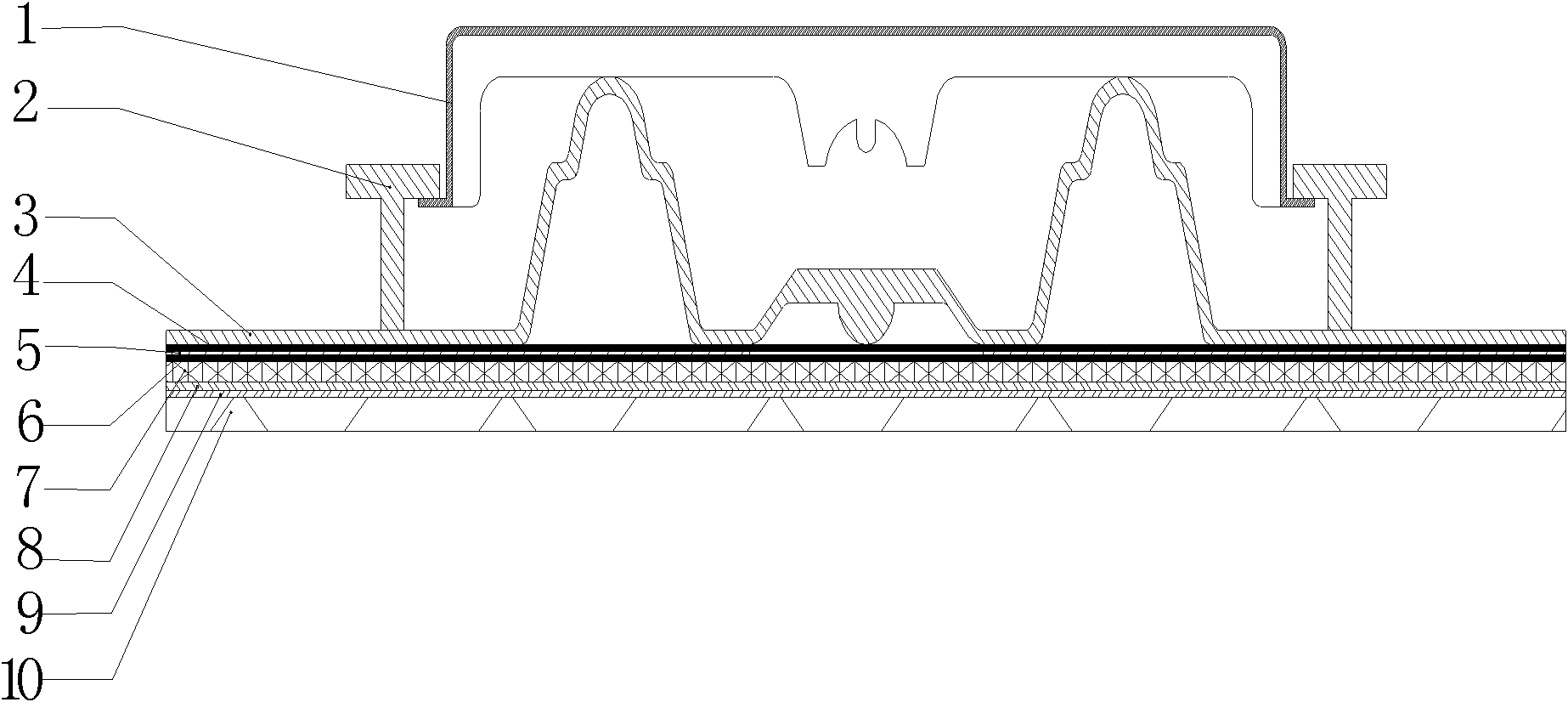

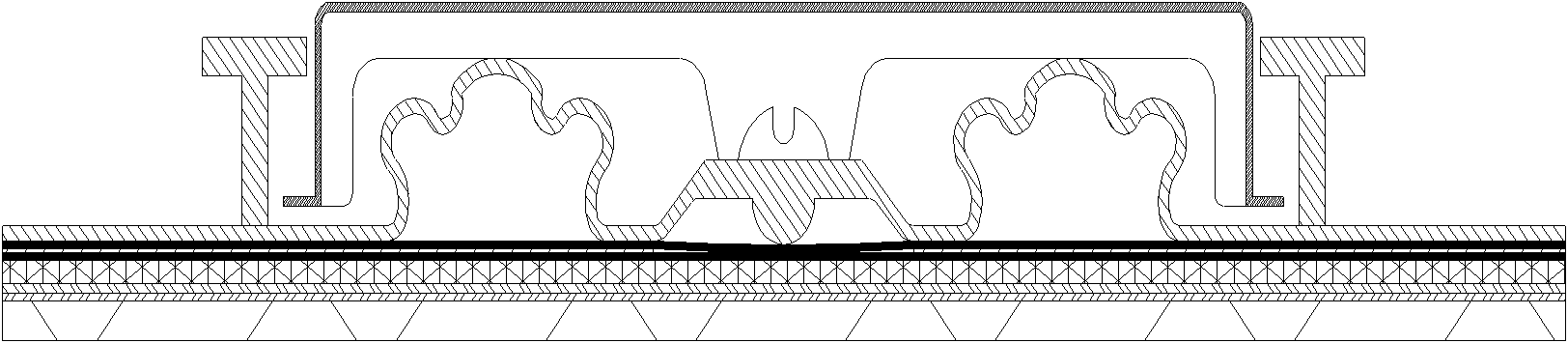

[0037] Such as figure 1 , figure 2 As shown, a thin backlit notebook computer button structure is assembled by the following parts in sequence: injection molding insert 1; button press frame 2; silicone spring pad 3; upper flexible circuit board 4; ; Lower flexible circuit board 6; Light guide plate 7; Diffusion plate 8;

[0038] A preparation method for a thin backlight notebook computer key, comprising the steps of:

[0039] Step 1: Three-dimensional printing of single-sided matte PC film;

[0040] Step 2: Use the ultra-high pressure gas forming machine to form the semi-finished product of the three-dimensional printing of the single-sided matte PC film;

[0041] Step 3: Injection molding the semi-finished product formed by the ultra-high pressure gas molding machine;

[0042] Step 4: Carry out shape cutting on the semi-finished product of the injection molding of the insert;

[0043] Step 5: Assemble the keys of the thin backlit notebook computer.

[0044] Further te...

Embodiment 2

[0059] Such as figure 1 , figure 2 As shown, a thin backlit notebook computer button structure is assembled by the following parts in sequence: injection molding insert 1; button press frame 2; silicone spring pad 3; upper flexible circuit board 4; ; Lower flexible circuit board 6; Light guide plate 7; Diffusion plate 8;

[0060] A preparation method for a thin backlight notebook computer key, comprising the steps of:

[0061] Step 1: Three-dimensional printing of single-sided matte PC film;

[0062] Step 2: Use the ultra-high pressure gas forming machine to form the semi-finished product of the three-dimensional printing of the single-sided matte PC film;

[0063] Step 3: Injection molding the semi-finished product formed by the ultra-high pressure gas molding machine;

[0064] Step 4: Carry out shape cutting on the semi-finished product of the injection molding of the insert;

[0065] Step 5: Assemble the keys of the thin backlit notebook computer.

[0066] Further te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com