Contact structure for low-current molded case low-voltage circuit breaker

A low-voltage circuit breaker, low-current technology, applied in the directions of circuit breaker contacts, circuit breaker parts, circuits, etc., can solve the problems of not obvious current limiting effect, complicated installation of static contacts, and increased number of parts, etc., to achieve high performance The effect of lifting, reducing parts, increasing current limiting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

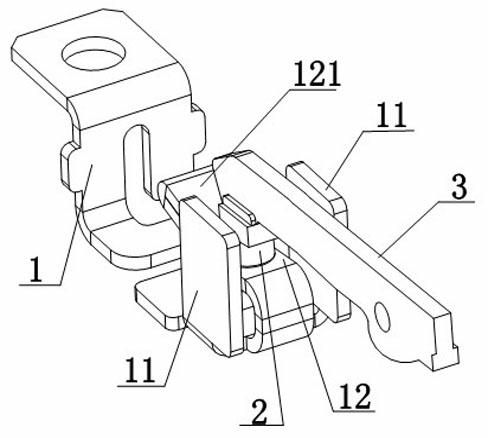

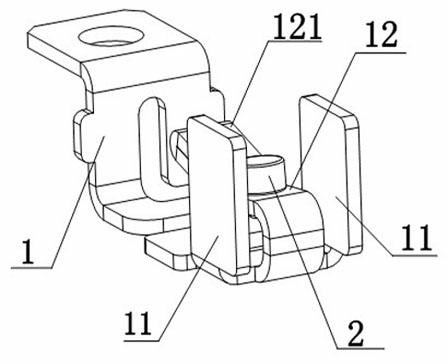

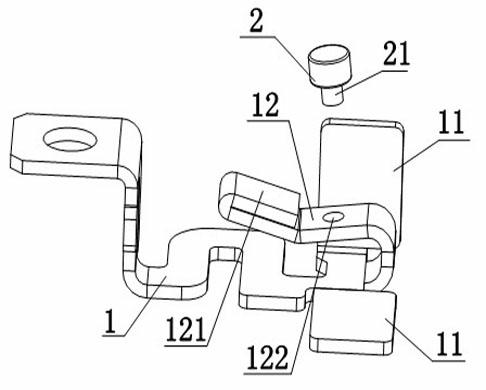

[0023] like figure 1 As shown, the present invention includes a static conductive rod 1, a static contact 2 and a movable contact 3, wherein the static conductive rod 1 is located in front of the movable contact 3, and the static contact 2 is located between the static conductive rod 1 and the movable contact 3. In between, the static contact structure includes a static conductive rod 1 and a static contact 2 .

[0024] like Figure 2-5 As shown, the static conductive rod 1 is made into a structure similar to a serpentine, and the material of the static conductive rod 1 is a ferromagnetic high-resistance alloy. The serpentine structure can increase the length of the static conductive rod 1, and the ferromagnetic high-resistance alloy can increase the resistance of the static conductive rod 1, thereby increasing the current limiting resistance of the circuit breaker and reducing the actual current flowing through the circuit breaker when breaking. A U-shaped boss ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com