Catalyst for reforming tar-containing gas, method for producing catalyst for reforming tar-containing gas, method for reforming tar-containing gas using catalyst for reforming tar-containing gas, and method for regenerating catalyst for reforming tar

一种制造方法、焦油气的技术,应用在催化剂再生/再活化、催化剂活化/制备、可燃气体净化/改造等方向,能够解决催化剂寿命短、经济不利等问题,达到重整活性高、碳析出率低、维持活性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

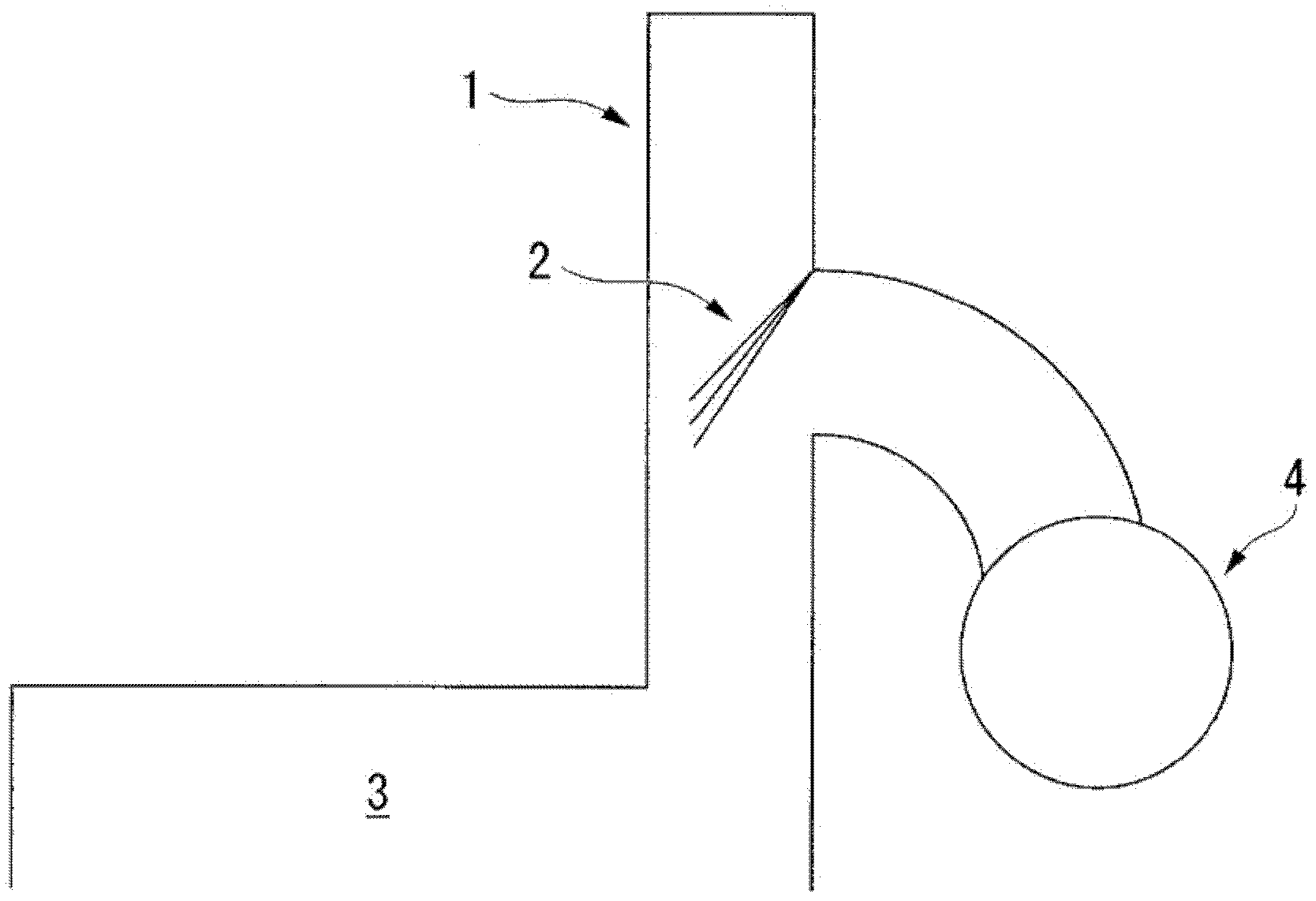

[0071] (First embodiment) Catalyst for reforming tar-containing gas

[0072] The catalyst for reforming tar-containing gas according to the first embodiment of the present invention is an oxide containing nickel, magnesium, cerium, and aluminum. The catalyst for reforming tar-containing gas contains at least one composite oxide (that is, consists of one or more composite oxides, or consists of a mixture of a composite oxide and a single metal oxide), and contains as a single compound Not more than 5% by mass of alumina (alumina phase).

[0073] Nickel functions as a main active component for reforming reactions between heavy hydrocarbons and water vapor, hydrogen, or carbon dioxide present in the gas or introduced from the outside. Even when a high concentration of hydrogen sulfide coexists in tar-containing gas, since the above-mentioned nickel metal is finely dispersed in clusters on the surface of the catalyst, the surface area becomes large, and even if the active metal p...

no. 2 Embodiment approach

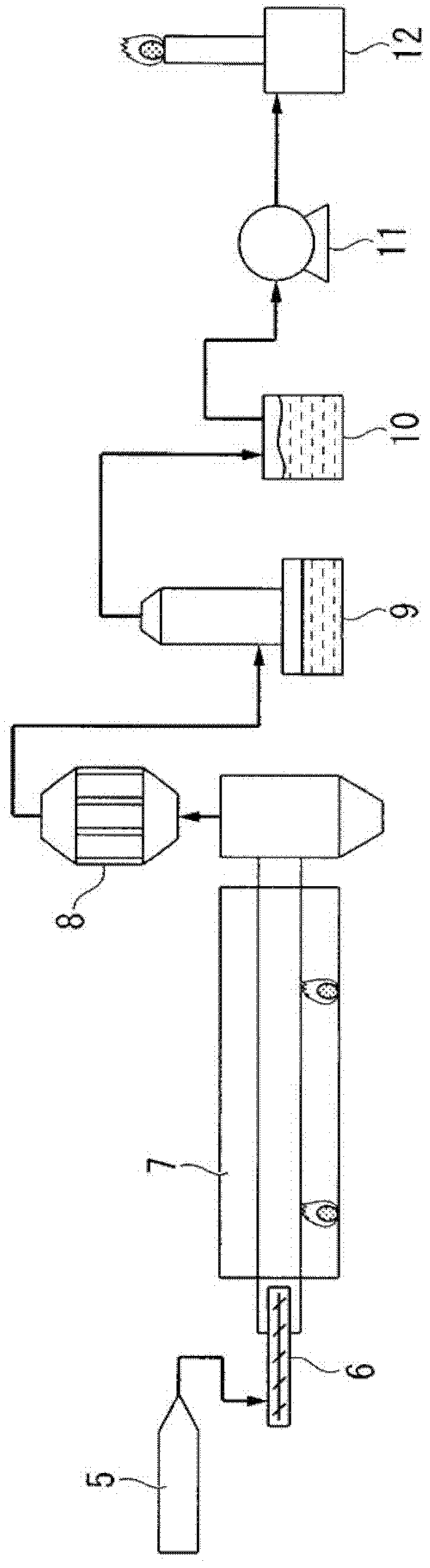

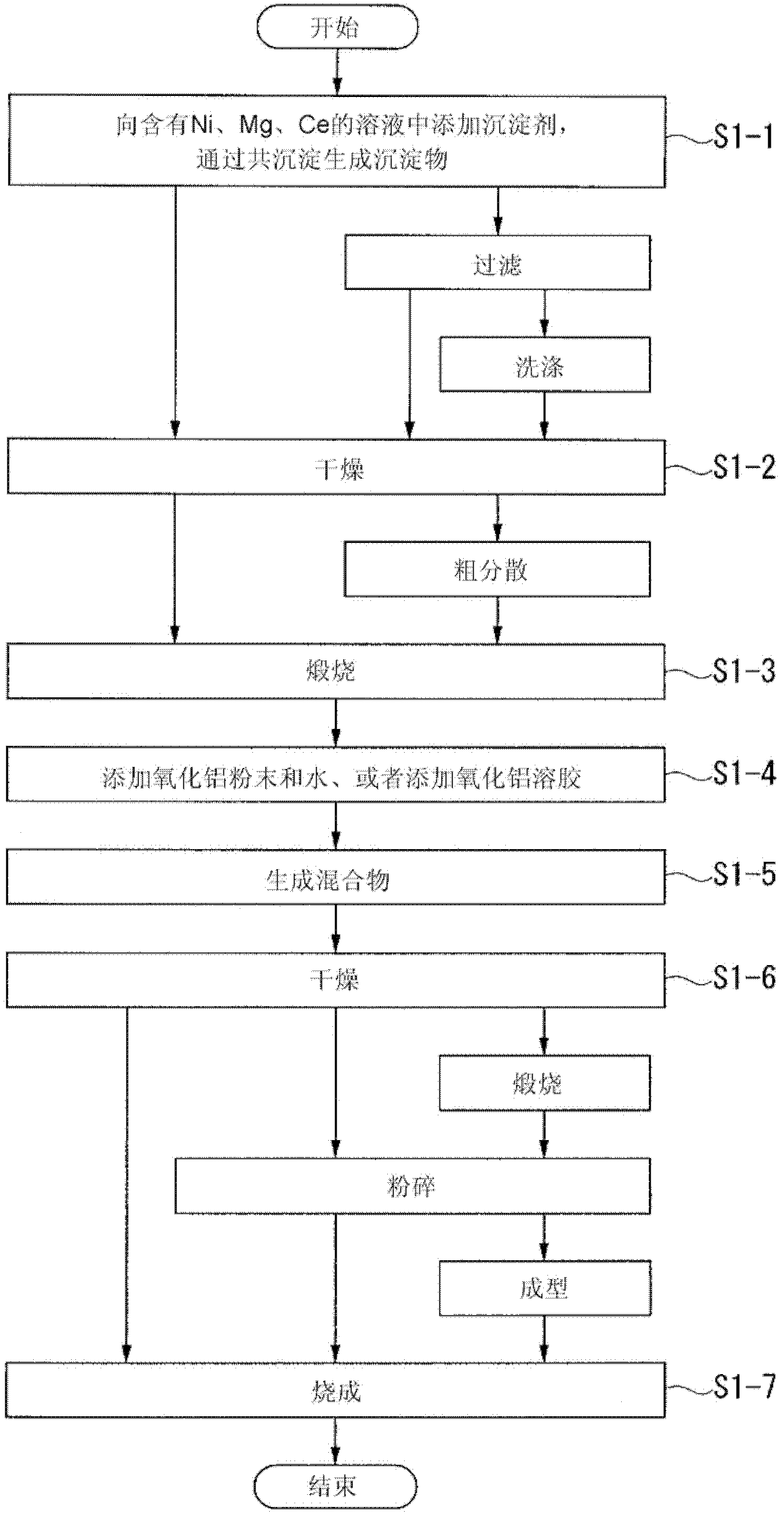

[0096] (Second Embodiment) Method for Producing a Catalyst for Reforming Tar-Containing Gas

[0097] Below, refer to Figure 3 ~ Figure 5 The shown flow chart describes the method for producing the tar-containing gas reforming catalyst according to the second embodiment of the present invention.

[0098] A second embodiment of the present invention is a method for producing a tar reforming catalyst used for reforming tar-containing gas. The tar-containing gas reforming catalyst referred to here refers to a metal oxide catalyst containing nickel, magnesium, cerium, and aluminum as constituent metals. The catalyst was produced as follows.

[0099] First, a precipitate is formed from a solution of a nickel compound, a magnesium compound, and a cerium compound by coprecipitation. The aluminum component is added after the co-precipitation or the formation of the precipitate to form an aluminum mixture containing nickel, magnesium, cerium, and aluminum. The aluminum mixture is d...

no. 4 Embodiment approach

[0127] (Fourth embodiment) Regeneration method of catalyst for reforming tar-containing gas

[0128] For the tar reforming catalyst built in the catalyst reactor, when the tar is converted into light chemical substances mainly composed of hydrogen, carbon monoxide, and methane, the carbon deposited on the surface of the catalyst or the heat obtained from the thermal decomposition process Sulfur components contained in the decomposed gas are adsorbed on the catalyst, thereby deteriorating the performance of the catalyst. Therefore, as a method for regenerating a degraded catalyst, water vapor is introduced into the catalyst reactor, and the carbon on the surface of the catalyst is removed by the reaction of water vapor and carbon, or the sulfur adsorbed on the catalyst is removed by the reaction of water vapor and sulfur, The catalyst can thus be regenerated. In addition, by replacing part or all of the water vapor with air, the carbon on the surface of the catalyst is removed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com