Crushing automation control table

A console and connection terminal technology, applied in the field of ore crushing automation control device, crushing automation console, to achieve stable and efficient operation, optimize operation, and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

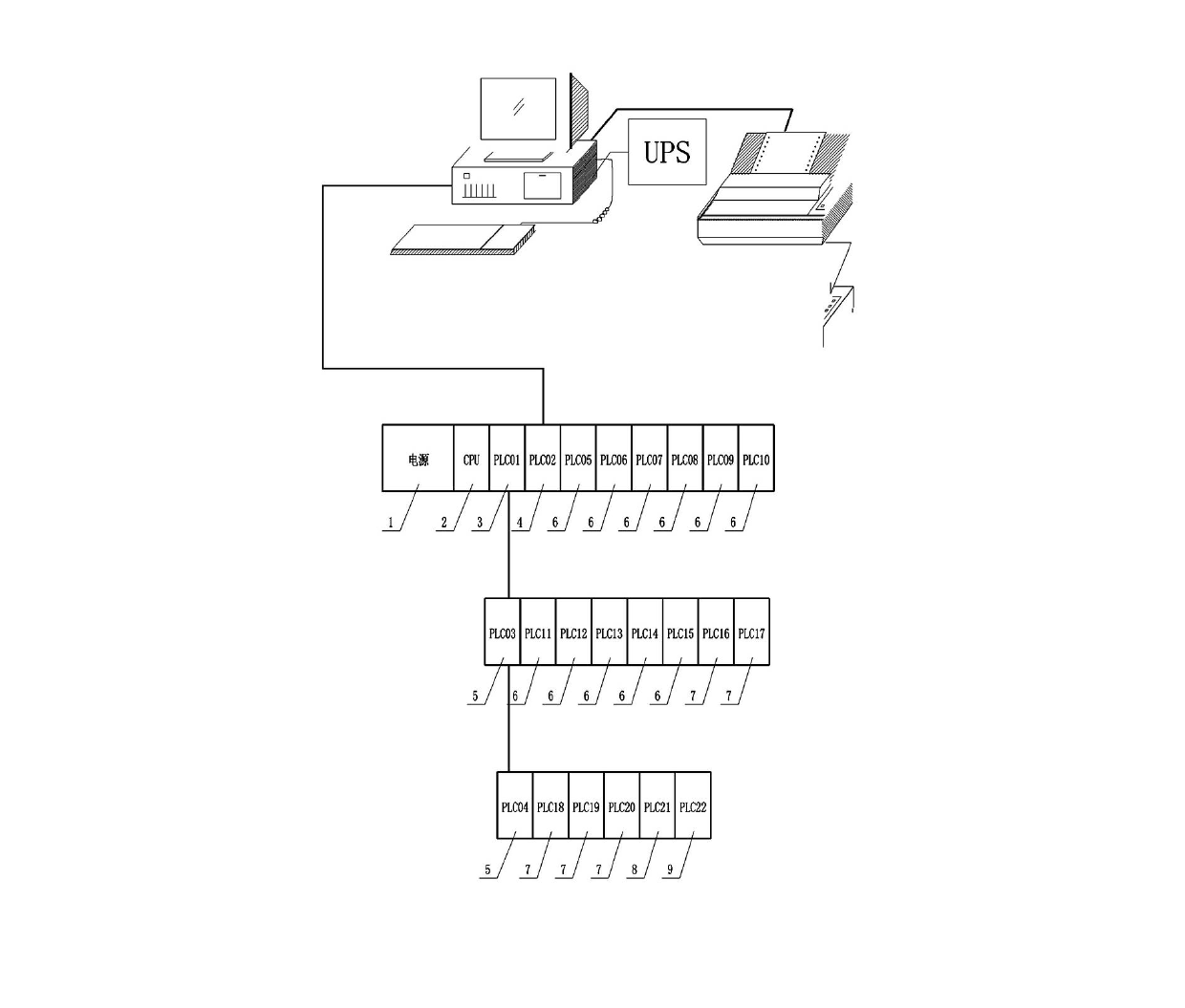

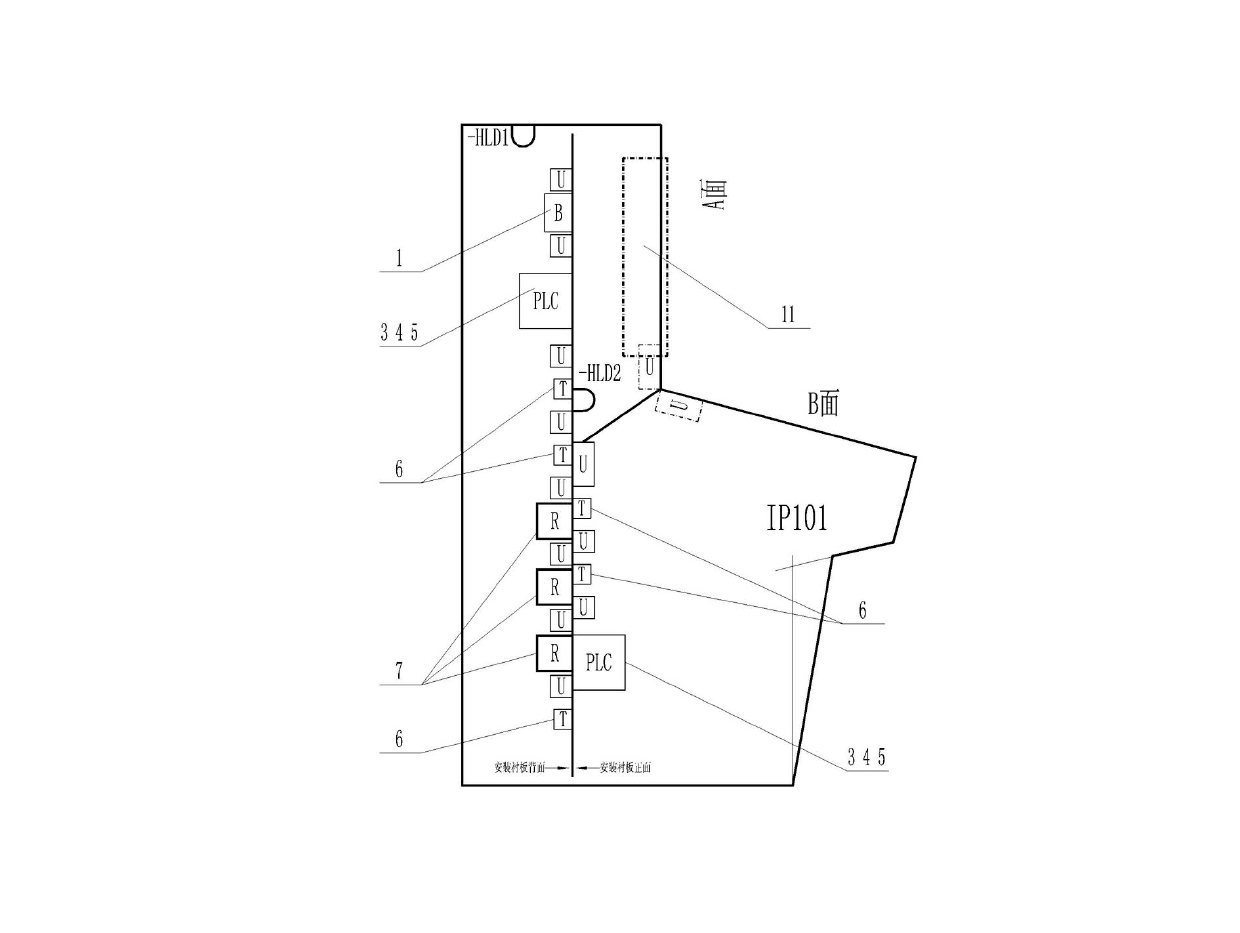

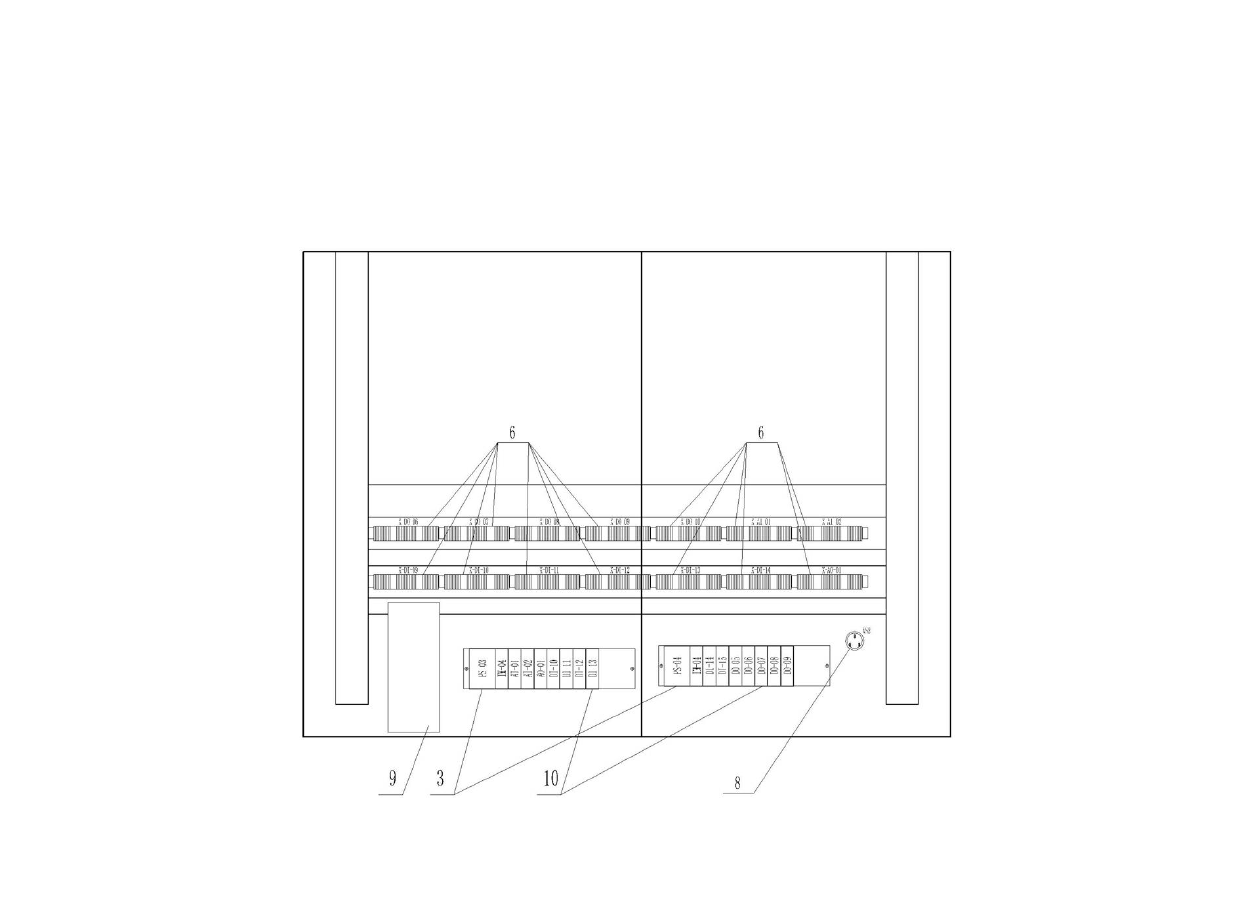

[0018] Such as figure 2 , Figure 5 to Figure 7 As shown, the present invention is a crushing automation console, which is provided with UPS power supply, PLC and various control buttons in the shell; the data points that need to be collected on site are connected to the terminal 2 on the crushing automation console through a control cable , the terminal 2 and the cable are connected to the CPU 4 of the PLC, the digital input and output module 5 is processed by the CPU 4 of the PLC, and then output to the digital input and output module 5, and the cable is connected to the wiring through the digital input and output module 5 Terminal 2 and connecting terminal 2 are connected to specific on-site actuators to realize the control of various analog and digital quantities on site;

[0019] Also be provided with host computer 9 in shell, host computer 9 realizes backstage control by RS485 bus line and PLC communication; Described host computer 9 is connected with CPU 4 of PLC by R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com