Molding process of progressive die of high temperature alloy sheet metal component with high flanging hole

A technology of high-temperature alloy and forming process, which is applied in the field of forming process of sheet metal parts, can solve the problems of limiting the production efficiency of sheet metal parts, high manufacturing and processing costs, and low precision, so as to save equipment and labor occupation, ensure quality and Consistency, to meet the effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

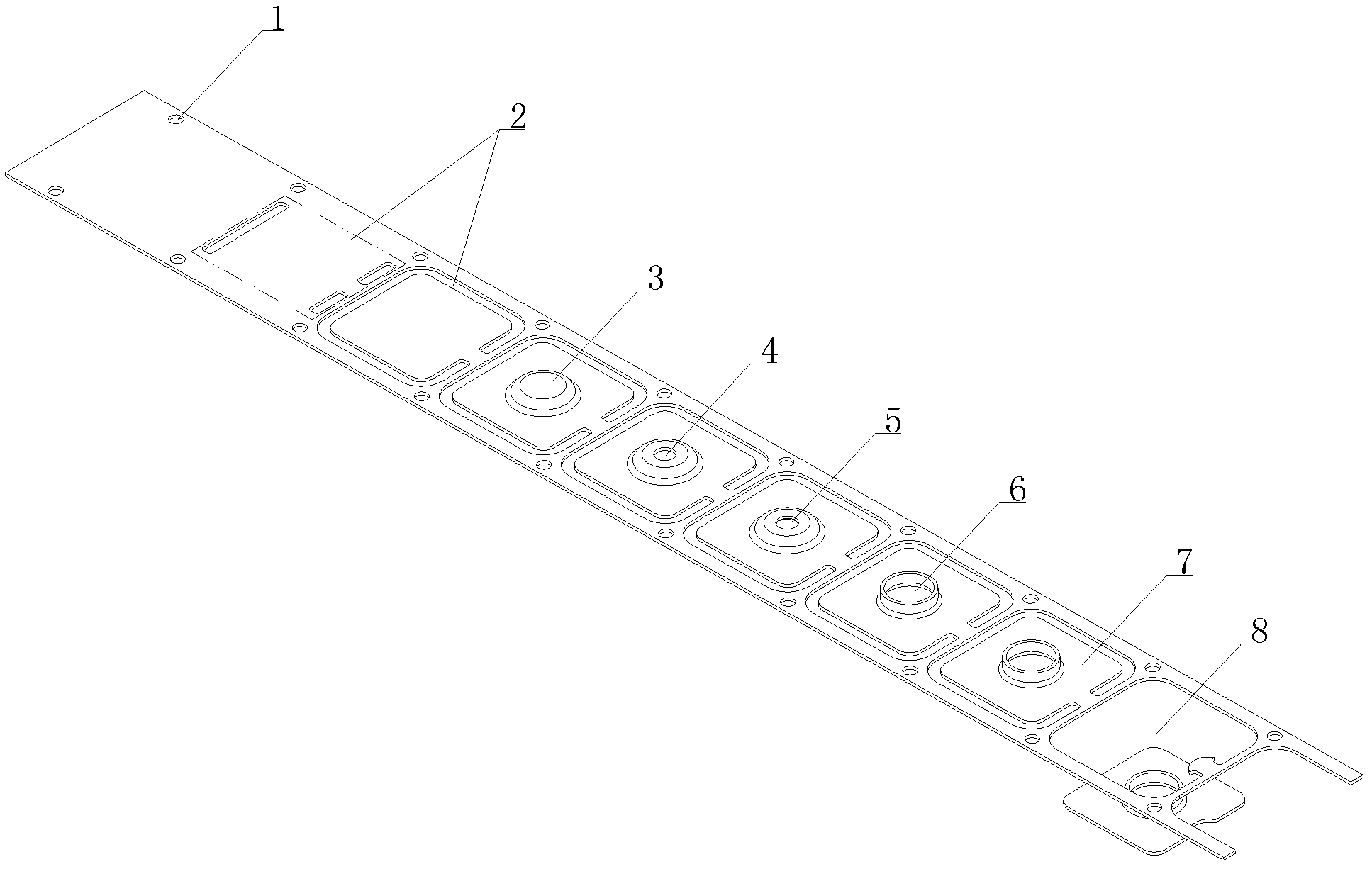

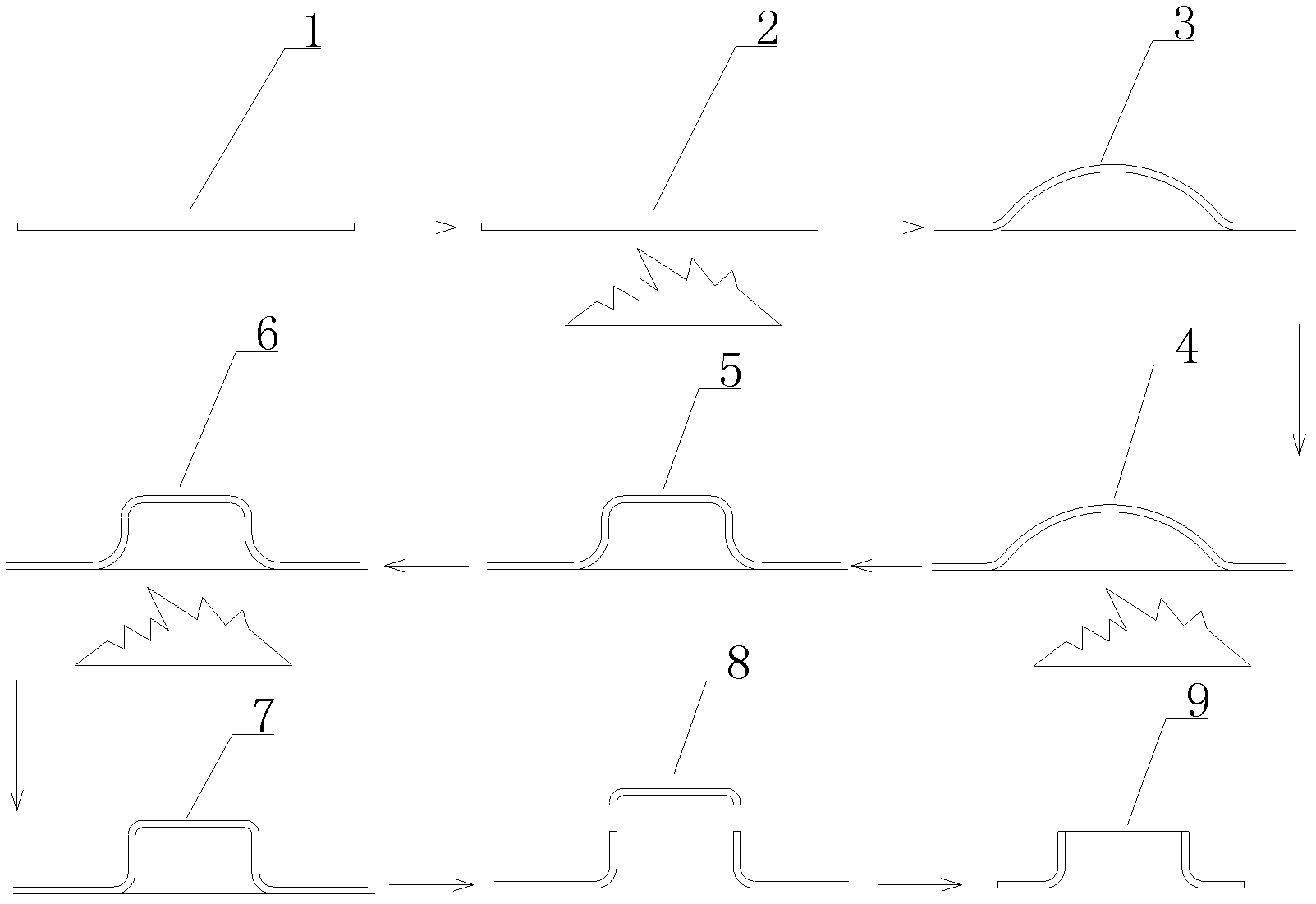

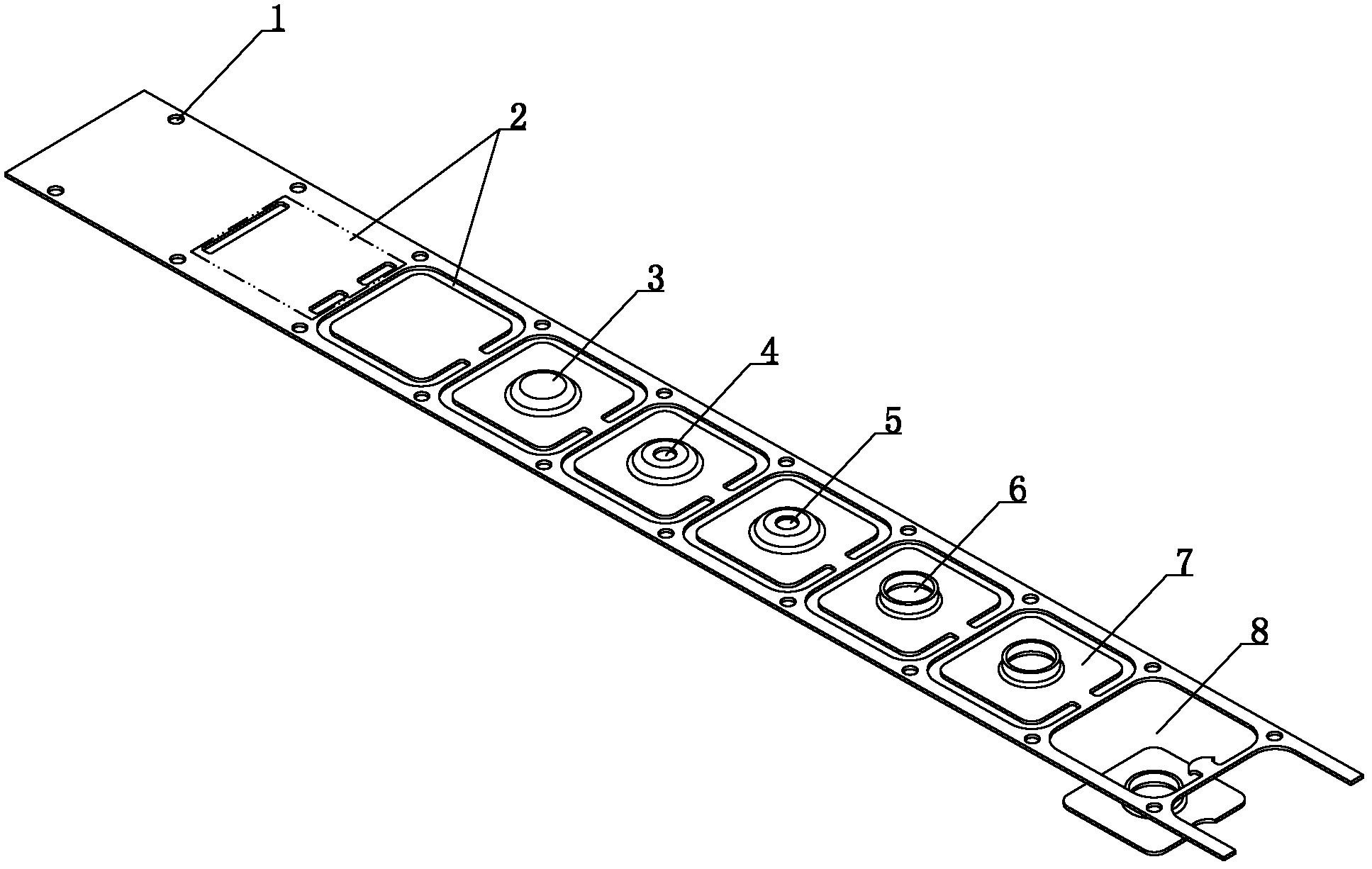

[0028] see figure 1 , a progressive die forming process for high-temperature alloy sheet metal parts with high flanging holes, including the following processes:

[0029] 1) Punch out the positioning hole 1, that is, place the material strip for making sheet metal parts on the workbench of the stamping equipment, and punch out the positioning holes near the two sides of the material strip;

[0030] 2) Press type 2, which is to move the material strip with punched positioning holes to the next second process, and use the above positioning holes as the positioning reference to press the indentation consistent with the outer contour of the prefabricated sheet metal parts on the material belt. , according to the structural characteristics of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com