Manufacturing method of automobile sound insulation pad

A technology of automobile sound insulation pad and manufacturing method, which is applied in the directions of chemical instruments and methods, lamination and layered products, etc., can solve the problems of complicated adjustment of acoustic performance, complicated production process, increase of production cost, etc., so as to ensure safety and save money. The effect of labor and productivity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

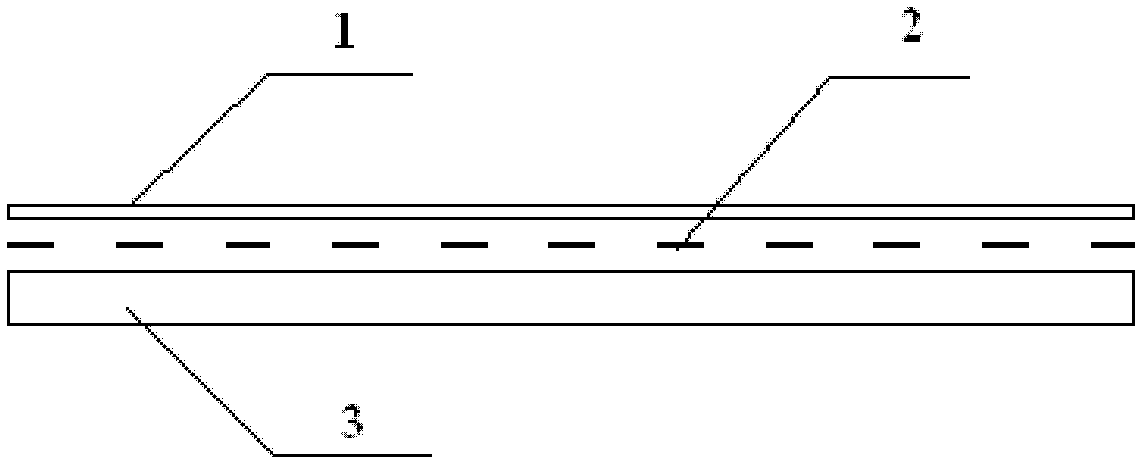

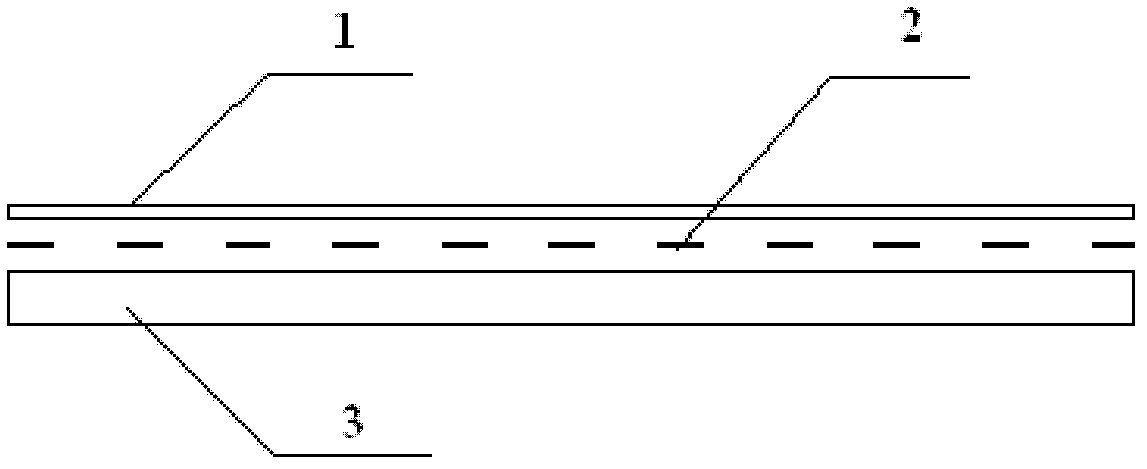

[0022] (1) Paving: such as figure 1 As shown, the pavements are stacked in the order of soft fiber mat 1, air-permeable sound-absorbing membrane 2 and hard layer fiber mat 3 from bottom to top. The air-permeable and sound-absorbing film is PE air-permeable and sound-absorbing film.

[0023] The composition of the soft layer fiber felt is 20% polyester fiber by mass fraction, 20% low melting point polyester fiber and 60% cotton fiber and regenerated fiber of chemical synthetic fiber; surface density: 500g / m 2 .

[0024] The hard layer fiber mat composition is 10% polyester fiber, 30% low melting point polyester fiber and 60% cotton fiber and regenerated fiber of chemical synthetic fiber; surface density: 500g / m 2 .

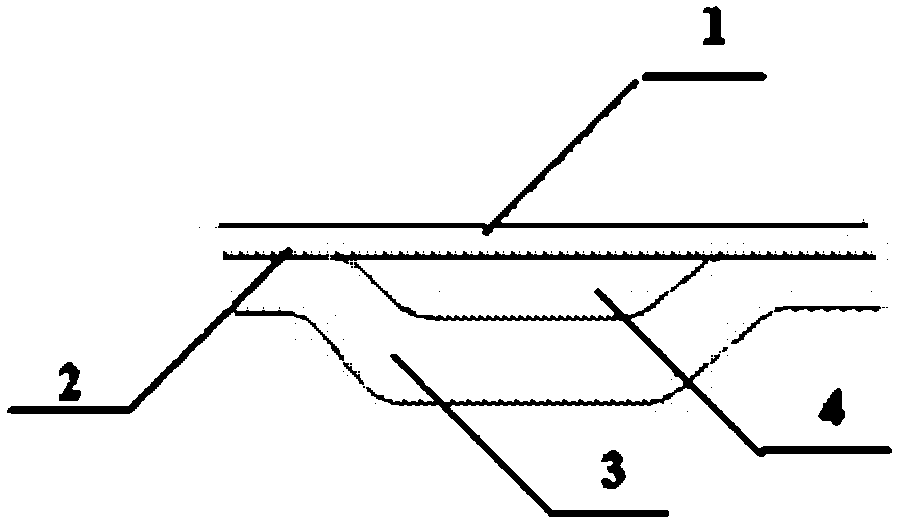

[0025] (2) Compression molding: Put the paved material into the forming mold for compression molding, the upper mold is vacuumed, and an air bag is formed in the product part, and at the same time, high-temperature steam is introduced to heat and shape the mater...

Embodiment 2

[0031] (1) Paving: stack the paving in the order of soft fiber mat, breathable sound-absorbing membrane and hard fiber mat from bottom to top;

[0032] (2) Compression molding: Put the paved material into the forming mold for compression molding, the upper mold is vacuumed, and an air bag is formed in the product part, and at the same time, high-temperature steam is introduced to heat and shape the material to obtain a semi-finished product; molding conditions: steam pressure : 3Mpa; Steam temperature: 220℃; Forming pressure: 10Mpa; Forming time: 60s; Vacuuming pressure: 0.03Mpa; Vacuuming time: 20s after forming;

[0033] (3) Cooling and shaping: put the pressed semi-finished product into the cooling fixture, and carry out cooling and shaping at room temperature, cooling time: 55s;

[0034] (4) Cutting: Use a punching device or a water jet to cut the dimensions and hole positions to obtain the product car sound insulation mat; punching device: punching pressure: 10Mpa, punchi...

Embodiment 3

[0037] (1) Paving: stack the paving in the order of soft fiber mat, breathable sound-absorbing membrane and hard fiber mat from bottom to top;

[0038] (2) Compression molding: Put the paved material into the molding mold for compression molding, vacuumize the upper mold, form air pockets in the product part, and at the same time inject high-temperature steam to heat and shape the material to obtain a semi-finished product; molding conditions: steam pressure : 2Mpa; Steam temperature: 200℃; Forming pressure: 7Mpa; Forming time: 50s; Vacuuming pressure: 0.02Mpa; Vacuuming time: 15s after forming;

[0039] (3) Cooling and shaping: put the pressed semi-finished product into the cooling fixture, and cool and shape it at room temperature. Cooling time: 40s;

[0040] (4) Cutting: use a punching device or a water jet to cut the overall size and hole position, punching device: punching pressure: 7Mpa, punching time: 5sec;

[0041] (5) Inspection: After passing the inspection without ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface density | aaaaa | aaaaa |

| Surface density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com