Fuel gas roller hearth continuous rapid aging furnace

A continuous aging furnace technology, used in furnaces, furnace types, heat treatment furnaces, etc., can solve the problems of poor furnace temperature uniformity, long circulation path, low efficiency, etc., to reduce floor space, reduce energy consumption, and ensure product quality. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

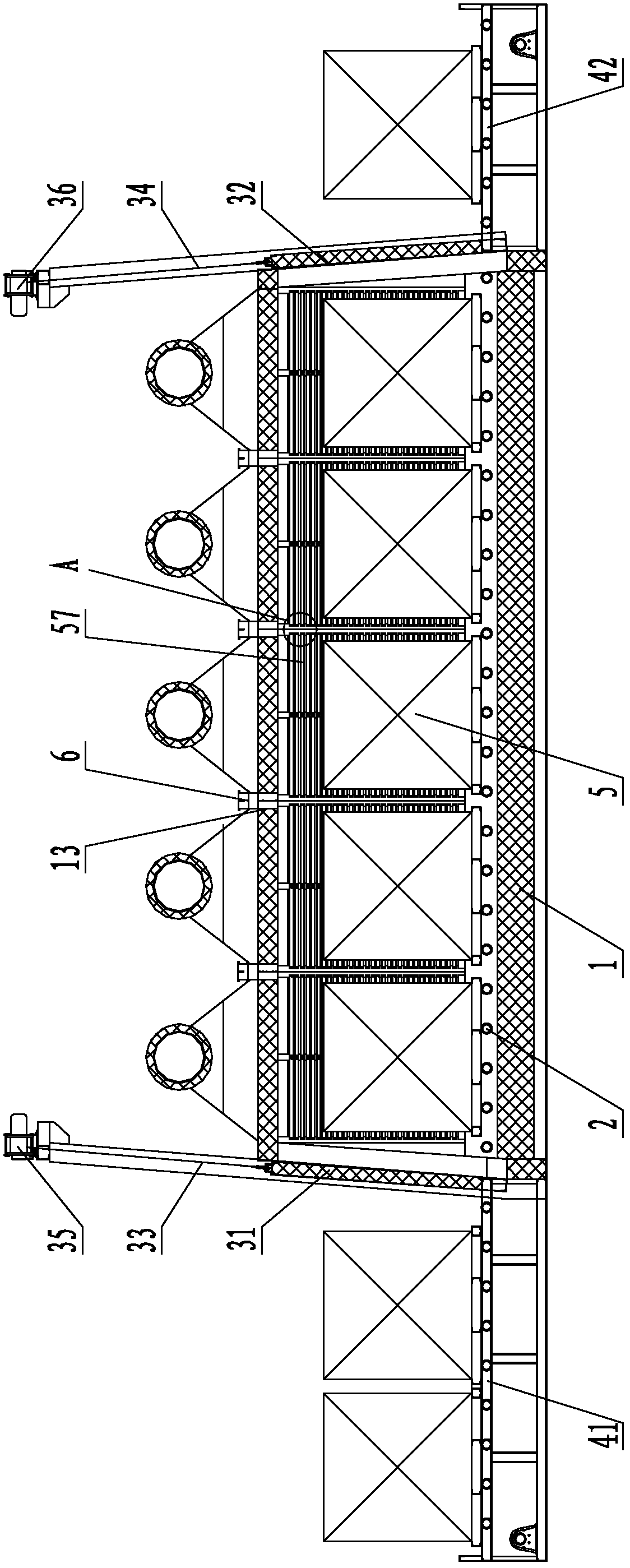

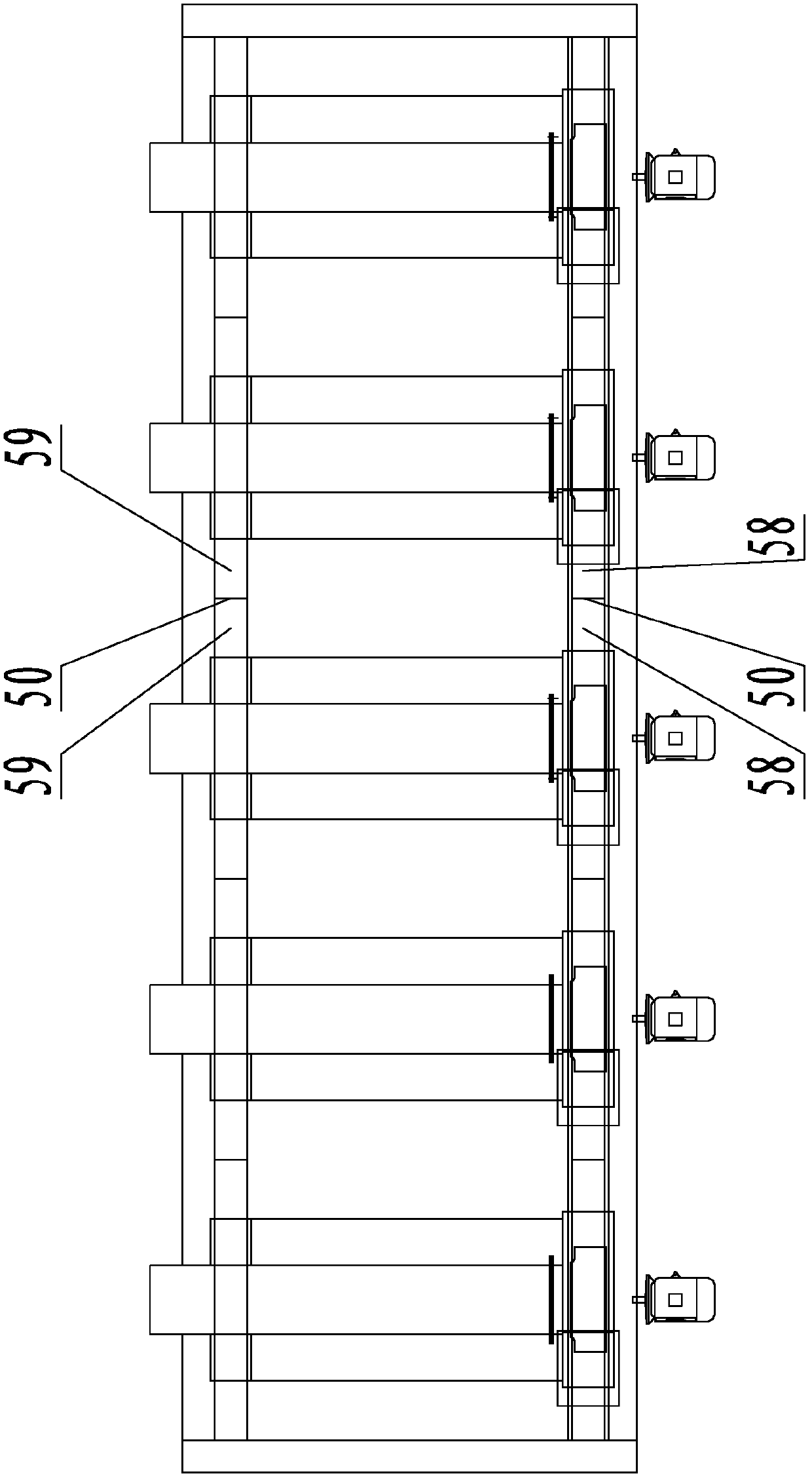

[0035] The gas-fired roller bottom continuous rapid aging furnace includes a furnace body 1 and a temperature control system. The bottom of the furnace body 1 is a roller table 2. The front and rear of the furnace body are respectively equipped with inlet and outlet furnace doors 31, 32 and inlet and outlet tables 41, 42. 1 is provided with five heat treatment units 5.

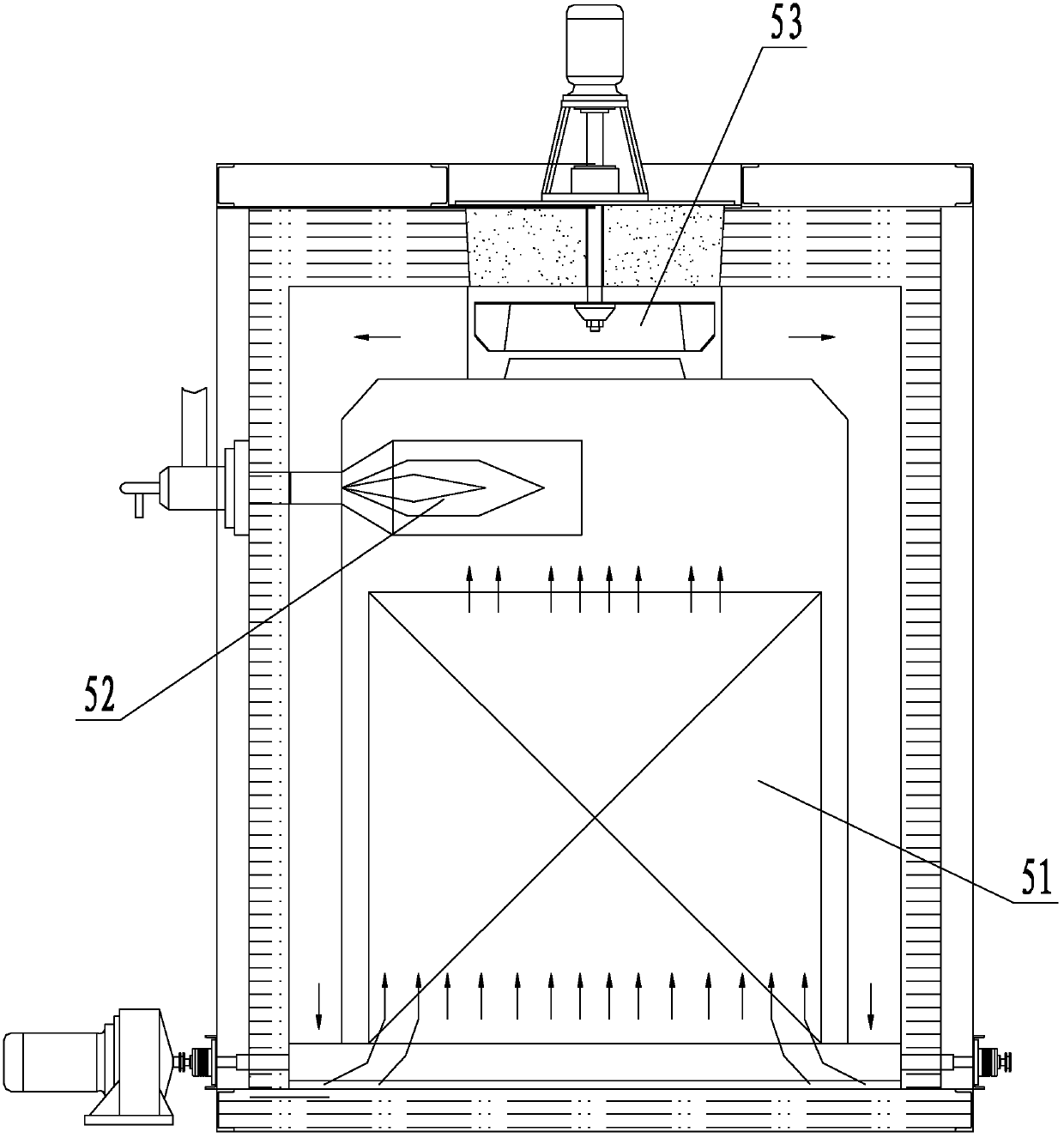

[0036] Each heat treatment unit 5 includes a workpiece area 51 , a combustion system 52 and a circulation fan 53 .

[0037] An independent combustion chamber 54 is arranged above the workpiece area 51, and the combustion system 52 and the circulation fan 53 are respectively arranged at the left and right ends of the independent combustion chamber 54. The chamber 54 is provided with a circulating air inlet 55 at the air outlet 532 of the circulating fan 53, and the independent combustion chamber 54 is provided with a circulating air outlet 56 under the combustion system 52;

[0038] The left and right sides of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com