High wear-resistant steel roller of belt conveyor and preparation method thereof

A belt conveyor, high wear-resistant technology, applied in metal material coating process, fusion spraying, coating, etc., can solve the problems of high production cost, improve service life, ensure safety and stability, and prevent corrosion and the effect of wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

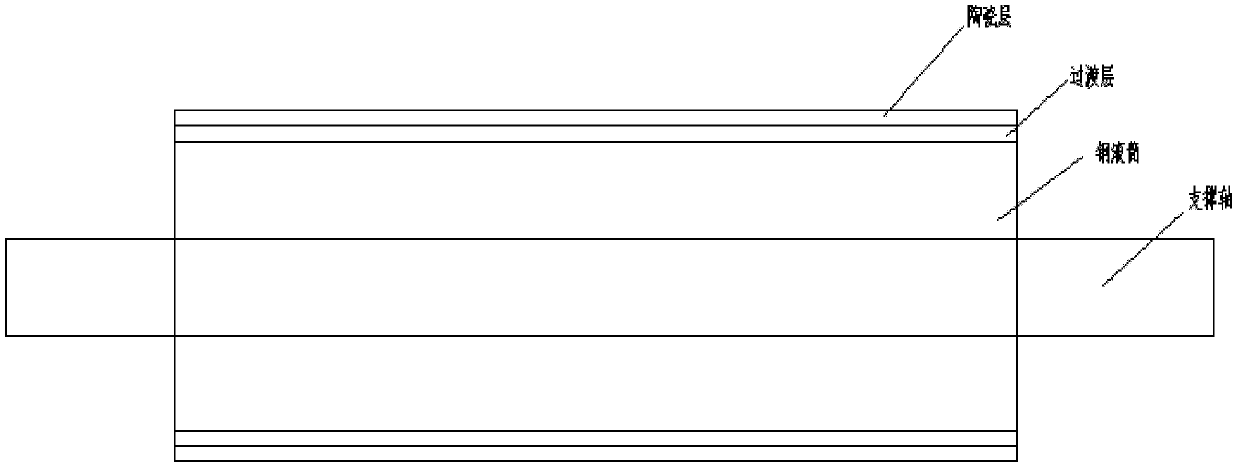

[0019] The first step, substrate pretreatment

[0020] After cleaning, sandblast the selected steel roller installed on the support shaft of the roller to make the surface roughness of the substrate Ra<0.8;

[0021] The second step is to prepare the transition layer

[0022] Take 1Kg of NiAl wire produced by Beijing University of Technology, install the substrate treated in the first step on the workbench of the spraying equipment, and prepare the first substrate of the transition layer under the first set of arc process conditions, and set the spraying current to 150A , voltage 30V, spraying air pressure 0.55MP, spraying distance 200mm, deposited transition layer 100μm;

[0023] The third step is to prepare the ceramic layer

[0024] Take 2Kg of hollow aluminum-titanium powder prepared by Shenyang Silicate Research Institute, preheat the first substrate prepared in the second step to 200°C, and then prepare the second substrate under the second set of flame spraying process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com