Full-poplar multilayer engineered solid wood flooring and production method thereof

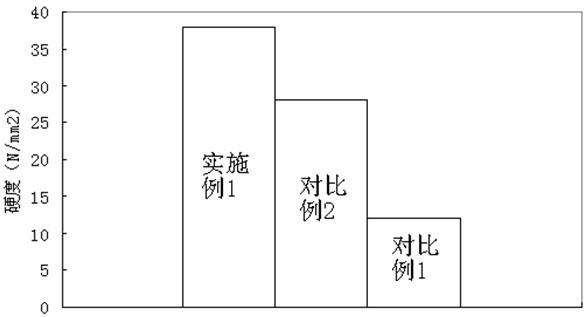

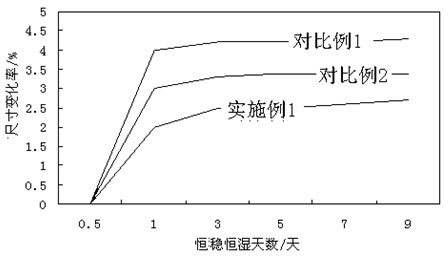

A technology of solid wood composite floor and production method, which is applied in the direction of layered products, wood layered products, chemical instruments and methods, etc. problem, to achieve the effect of good dimensional stability, low manufacturing cost and strong bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

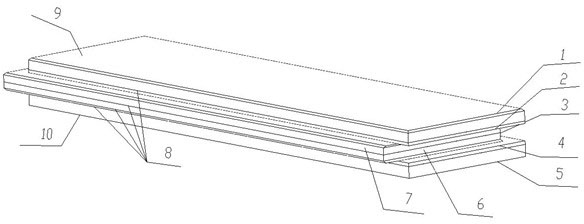

Image

Examples

Embodiment 1

[0024] (1) Cut off the poplar logs, cook them, peel them off, cut them into poplar veneers, and dry them to ensure that the moisture content of the poplar veneers after drying is 8%, and the thickness of the surface veneers must be 2.0MM, as a paint surface, The thickness of other layers of veneer is 1.0MM;

[0025] (2) The poplar veneer is impregnated with resin. Put the poplar veneer into the vacuum kettle, evacuate to 1500Pa, and keep it for 1 hour; then the prepared MF impregnation solution with a concentration of 50% by weight (solid content 80%, pH 8.2-9.7, viscosity 700- 1100mPa.s, the grade is Sumirez? Resin 613, melamine formaldehyde resin glue solution l000ml manufactured by Sumitomo Chemical Industry Co., Ltd. is prepared by adding distilled water 600ml) into the container in the vacuum kettle, and the poplar veneer is required to be completely immersed in the impregnating solution , and then soaked for 1 hour under vacuum. After slowly degassing, take out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com