Automatic exhaust cooling system

A cooling system and automatic exhaust technology, which is applied in the direction of engine cooling, liquid cooling, coolant flow control, etc., can solve the problem that air bubbles are not easy to discharge, and achieve the effect of ensuring heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

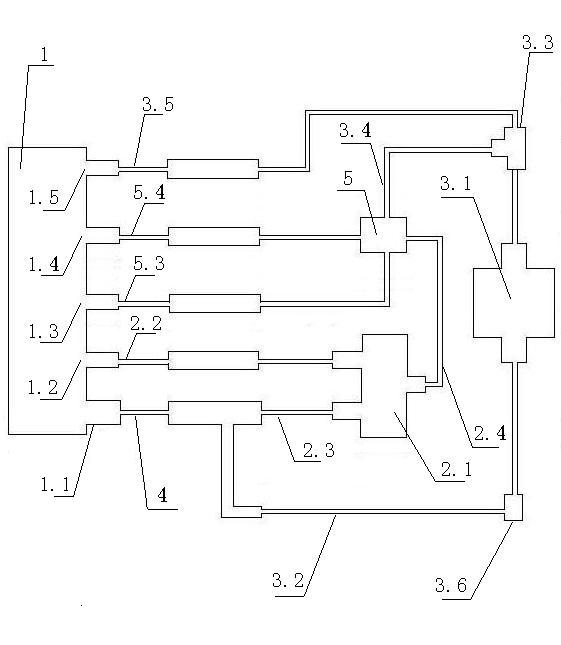

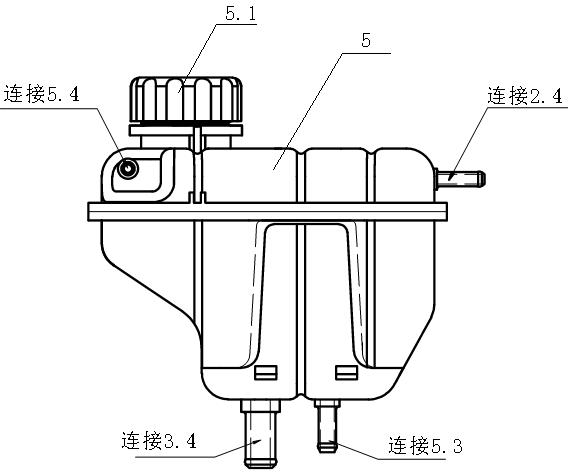

[0024] An automatic exhaust cooling system includes a large circulation pipeline connected to an engine water jacket 1, a small circulation pipeline and an expansion tank 5.

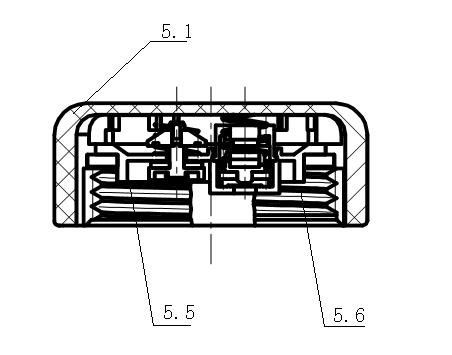

[0025] People's Communications Publishing House 2001.5 "Automobile Engineering Handbook-Design" page 182 discloses a general layout of an automobile cooling system. In this embodiment, the large circulation pipeline, the small circulation pipeline and the expansion tank 5 connected to the engine water jacket 1 can adopt the components and their connection methods disclosed in the above manual. In particular, in this embodiment, the expansion water tank 5 is preferably the pressurized auxiliary water tank disclosed on page 189 of the manual, and the thermostat may not have an exhaust valve.

[0026] Because the engine layout of the mini-car is mid-mounted, and in order to ensure the minimum ground clearance of the vehicle, the engine of the mini-car is tilted at a certain angle, causing the thermostat to ...

Embodiment 2

[0031] An automatic exhaust cooling system includes a large circulation pipeline connected to an engine water jacket 1, a small circulation pipeline and an expansion tank 5. When the engine temperature is lower than 85°C, the circulating water in the engine water jacket 1 directly enters the small circulation pipe through the adjustment of the thermostat installed on the water jacket water outlet 1.1 or the water jacket water inlet 1.2 of the engine water jacket 1 Road; when the engine temperature is higher than 85°C, through the regulation of the thermostat, the circulating water directly enters the large circulation pipeline and the small circulation pipeline.

[0032] Further, the water jacket water outlet 1.1 of the engine water jacket 1 is connected to the return water pipe 3.5 through the water outlet pipe 4 in one way, and connected to the radiator water inlet pipe 2.3 in the other way. The small circulation pipeline includes a heater 3.1 whose water inlet is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com