Novel Schottky flip-chip and manufacturing process thereof

A manufacturing process and flip-package technology, applied in the field of new Schottky flip-package chips and manufacturing processes, can solve the problems of short distance, low isolation, increased thickness, etc., to improve product work efficiency and meet high precision requirements, the effect of improving isolation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

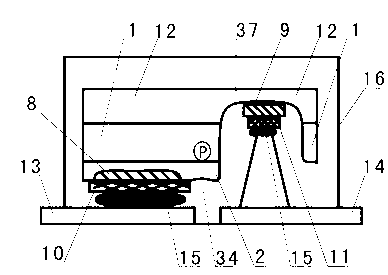

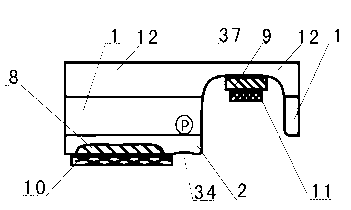

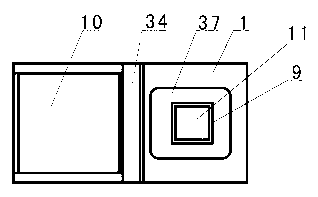

[0025] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0026] Such as figure 1 , figure 2 with image 3 As shown, the novel Schottky flip-pack chip in the present invention includes package body 16, chip positive pole 13, chip negative pole 14, silicon wafer 12, silicon wafer positive pole 10 and silicon wafer negative pole 11, and the total thickness of package body 16 is 0.6- 0.7mm; the silicon wafer positive pole 10 is connected to the chip positive pole 13, and the silicon wafer negative pole 11 is connected to the chip negative pole 14; the silicon wafer positive pole 10 and the silicon wafer negative pole 11 are located on the same side of the silicon wafer 12 ( figure 1 with figure 2 The positive electrode 10 of the silicon wafer is located on the surface of the silicon wafer 12, and a groove 37 is arranged beside the positive electrode 10 of the silicon wafer, and the negative electrode 11 of the silicon wafe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com