Application of conductive ink in electronic tag antenna

A technology of conductive ink and electronic label, applied in the direction of radiating element structure and other directions, can solve the problems of high cost of aluminum etching antenna, waste metal solution pollution, thick antenna thickness, etc., and achieve low cost, uniform and smooth film layer, and excellent performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

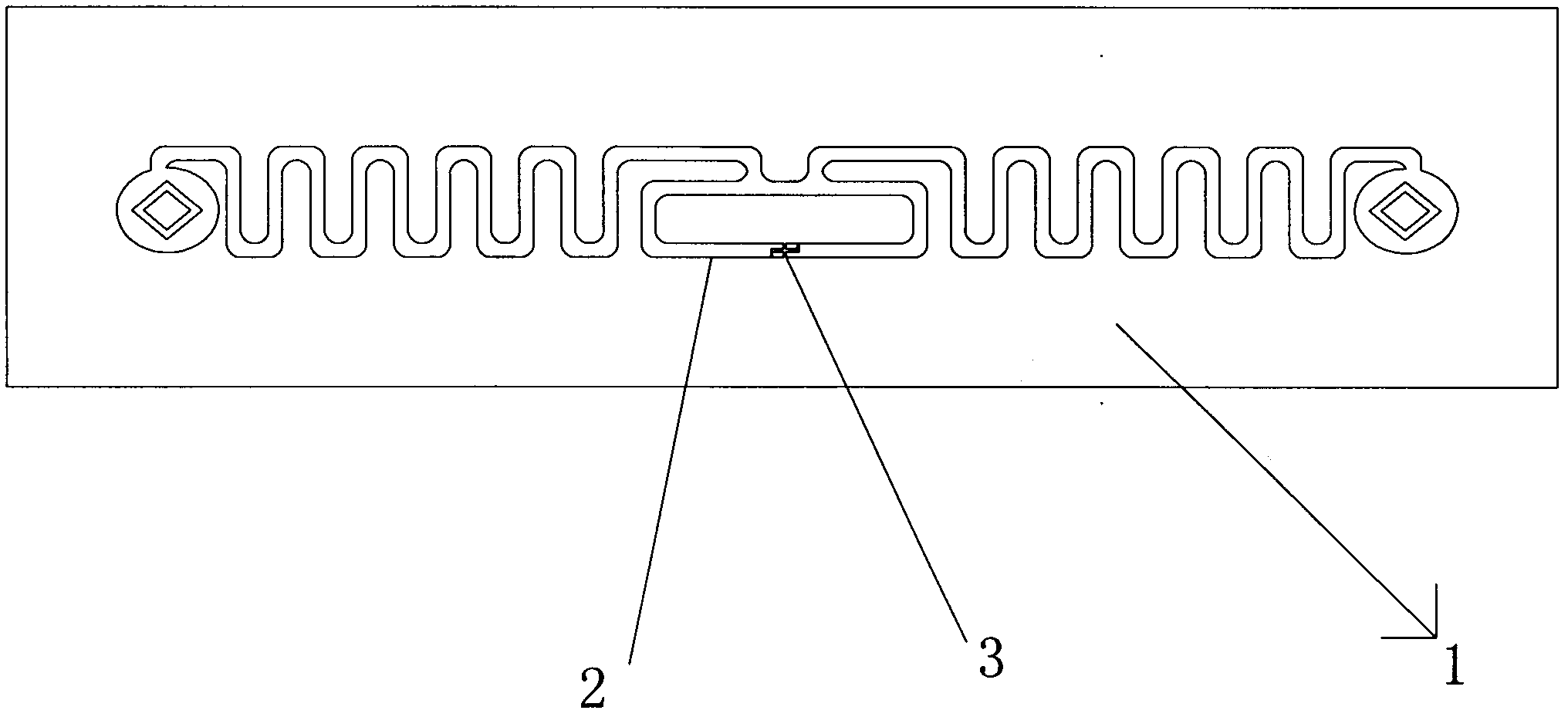

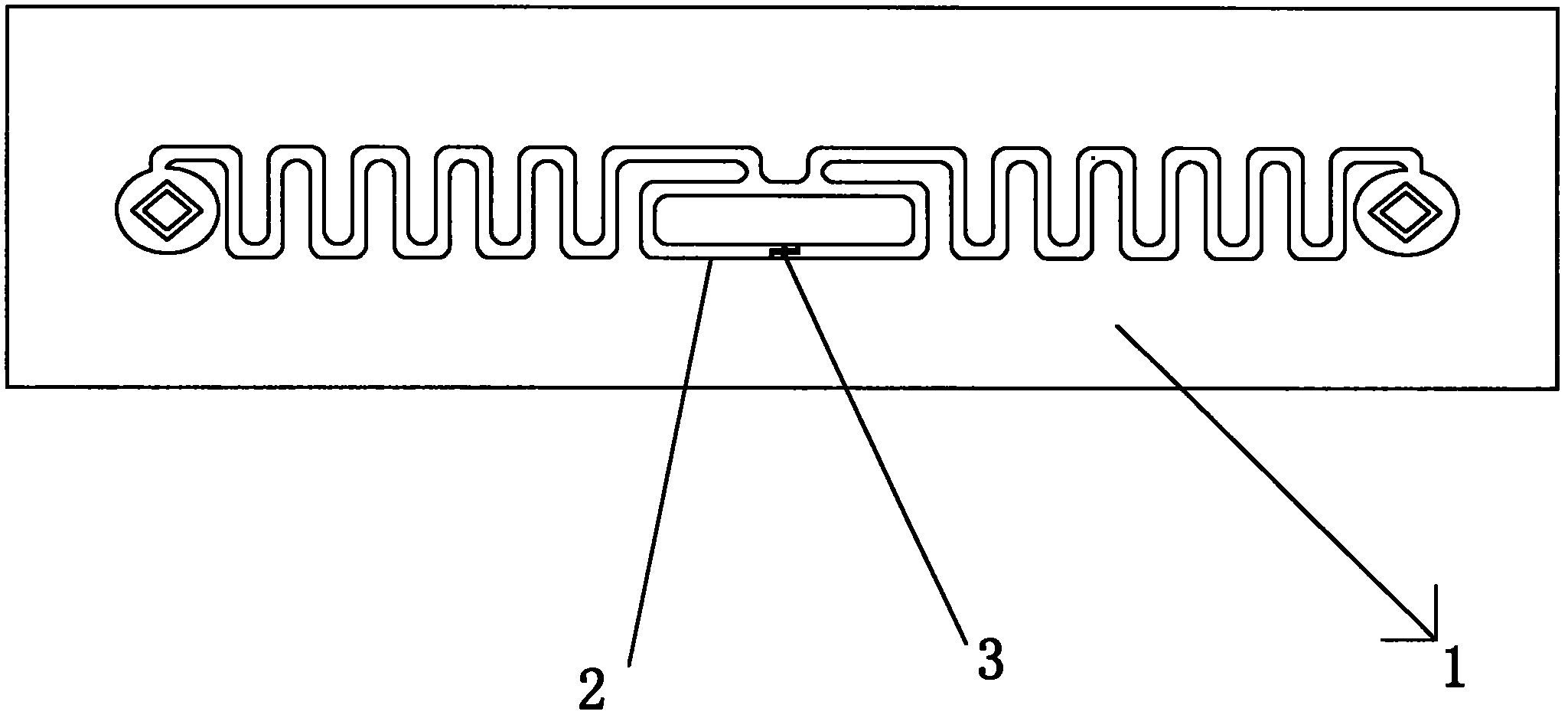

[0010] Further illustrate the present invention in conjunction with accompanying drawing and example, figure 1 It is an electronic label made by the invention. Among them, the antenna 2 of the electronic tag uses silver paste conductive ink to print the antenna pattern on the substrate through a large roller printing machine. The substrate of this example is paper. The silver paste conductive ink model is PGI-722, and the thickness of the paper is 0.12 mm, the thickness of the silver paste conductive ink antenna is 0.002mm, which is almost negligible.

[0011] Conductive ink is a special ink, which can add conductive carrier to UV ink, flexographic water-based ink or special offset printing ink to make the ink conductive. Conductive ink is mainly composed of conductive fillers (mainly metal powders, metal oxides, non-metallic powders and other composite powders), linking agents (mainly synthetic resins, photosensitive resins, low melting point plexiglass, etc.), additives (ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com