High-power centralized microwave rectifier circuit

A rectifier circuit and high-power technology, applied in the field of centralized microwave rectifier circuits, can solve problems such as the limitation of power capacity of rectifier circuits, the inability to meet the requirements of high-power microwave energy transmission, etc., to reduce the occupied area and the number of branches to be easily adjusted , the circuit compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

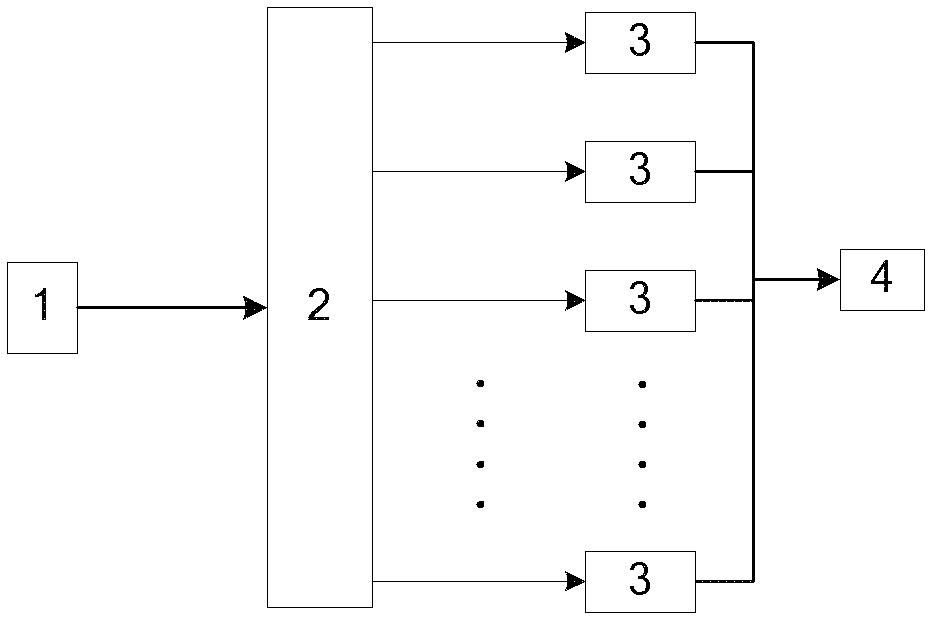

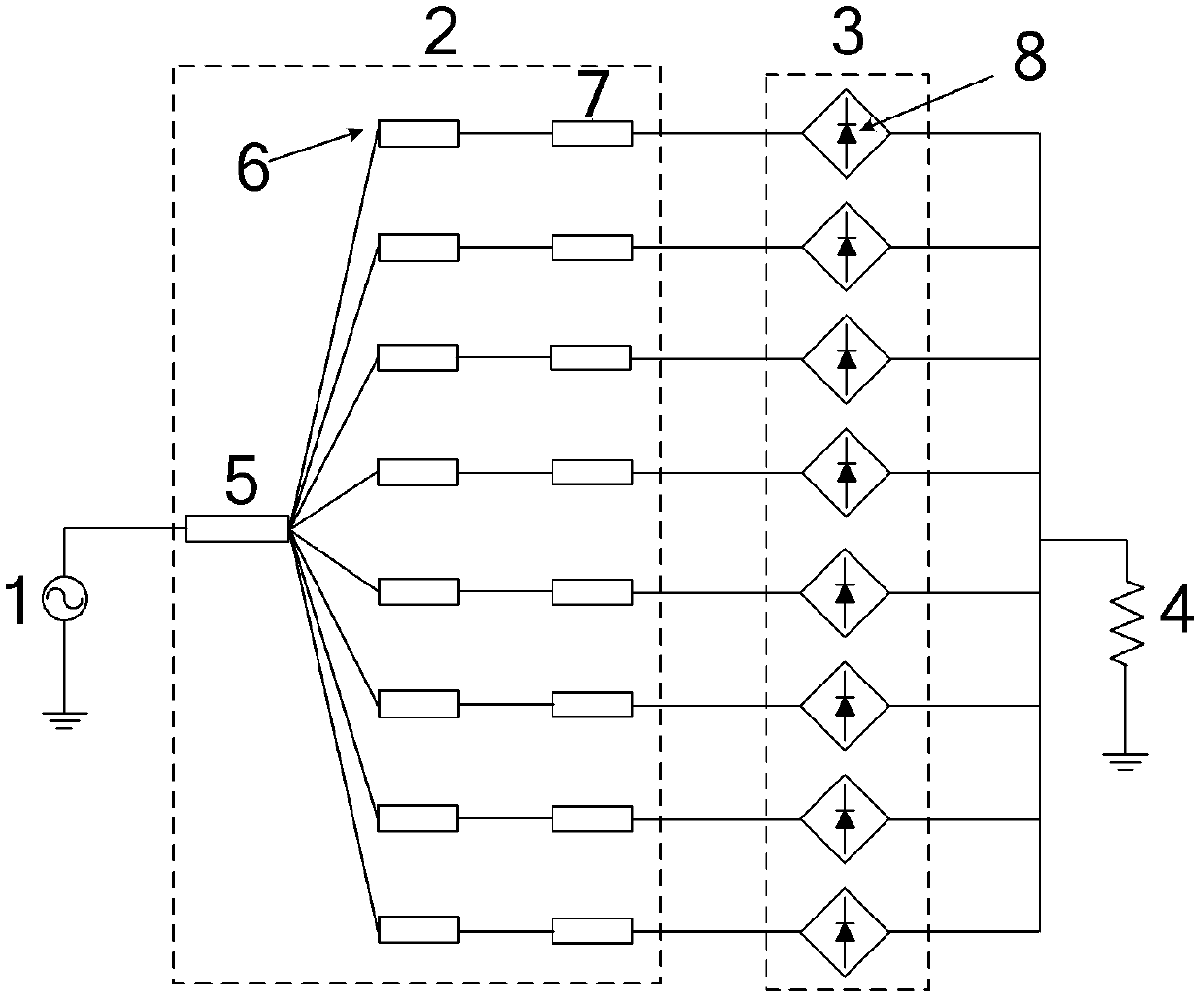

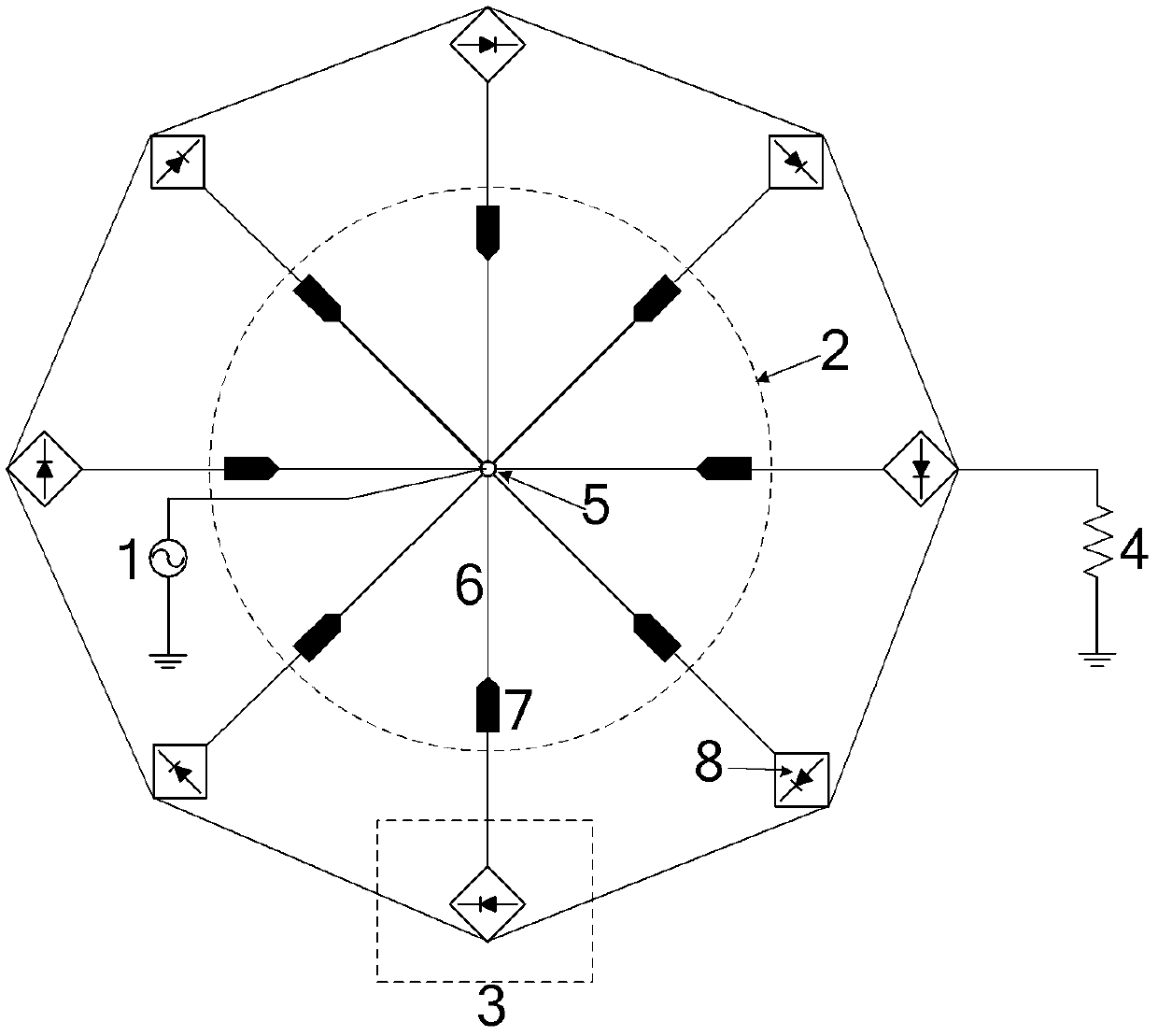

[0028] Such as figure 1 , figure 2 and image 3 Shown: Microwave energy (single frequency) is generated from microwave source 1, and enters power dividing circuit 2 through input terminal 5 of microstrip power dividing circuit. The output of power dividing circuit is divided into eight branches, and the eight branches are distributed in the shape of "m". ; Each branch is carried out impedance matching through 1 / 4 wavelength impedance transformation microstrip line 6 respectively, from the 400Ω matching at the input end 5 of the microstrip power dividing circuit to the standard impedance at the output 7 places of the microstrip power dividing circuit, the microstrip power The splitter output 7 has the same width as the input end 9 of the microstrip rectifier circuit 3, realizing a natural transition; the microstrip rectifier circuit 3 adopts multiple Schottky microwave diodes to be connected in series / parallel to be equivalent to a high-power microwave diode to realize power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com