Fiber-transmission-based interface circuit

An interface circuit and optical fiber transmission technology, which is applied in the field of interface circuits, can solve the problems of few types of circuit interface boards, unable to meet the special requirements of the automatic control system of rolling mill thickness, and signal attenuation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

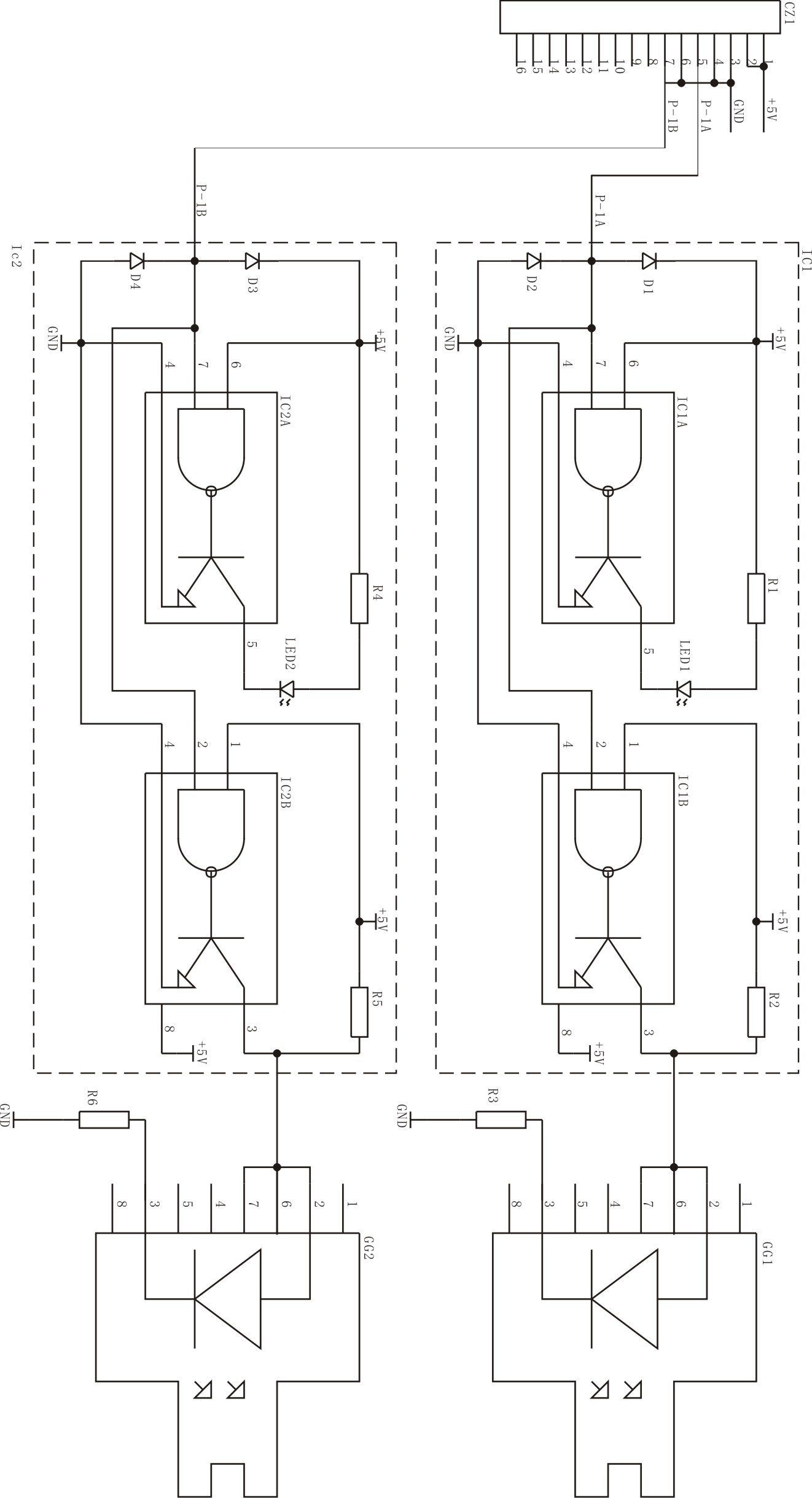

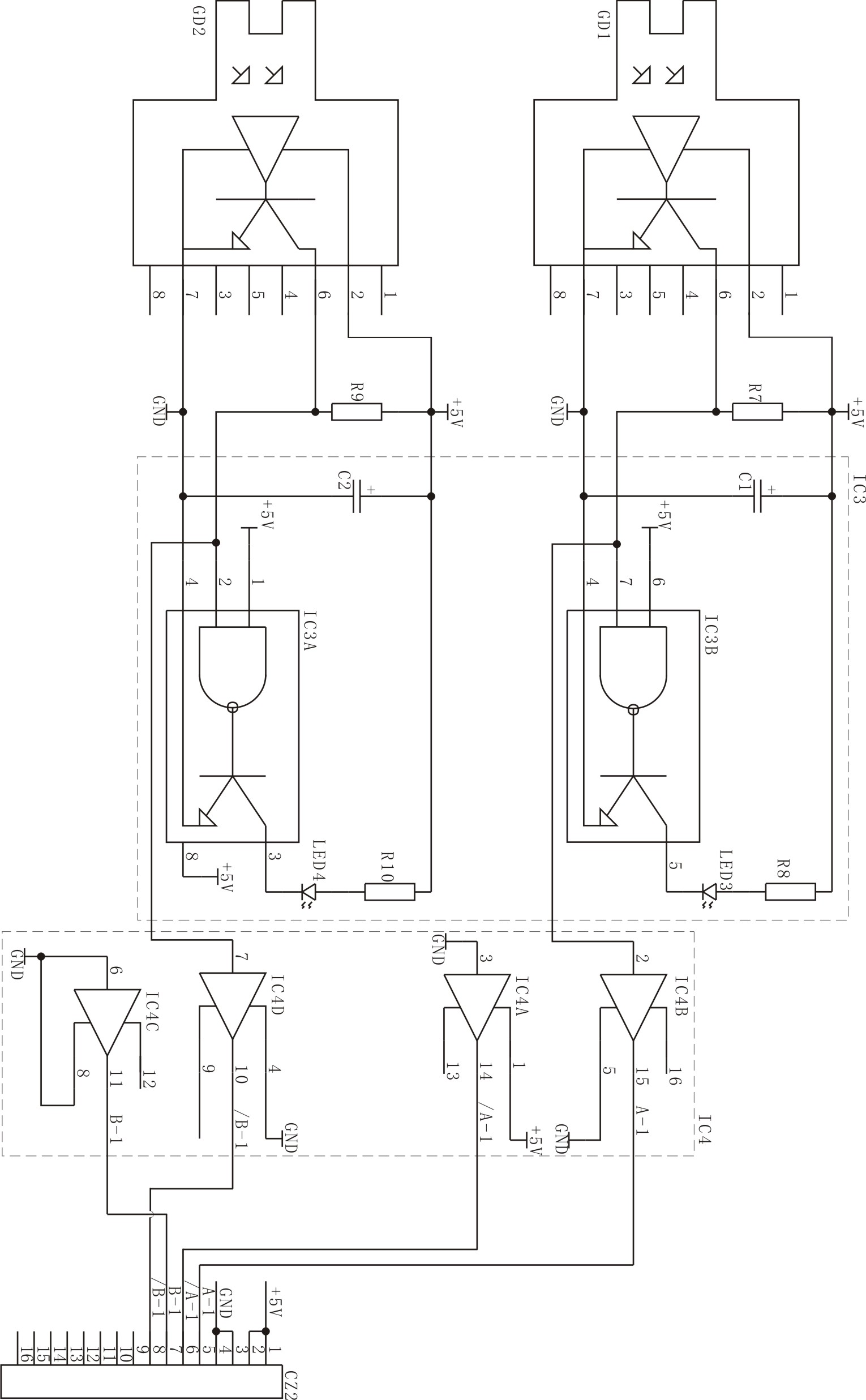

[0013] The technical solution of the present invention will be described in further detail below through embodiments and in conjunction with the accompanying drawings.

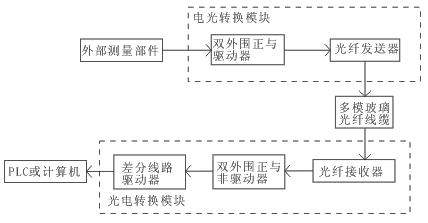

[0014] Such as figure 1 As shown, the present invention is based on an interface circuit for optical fiber transmission, which includes an electro-optic conversion module, a transmission fiber and a photoelectric conversion module. Composed of positive and non-driver and differential line driver, the external measurement component is connected to the input end of the double peripheral positive and driver, the double peripheral positive and driver, optical fiber transmitter, optical fiber receiver, dual peripheral positive and non driver and differential line driver in sequence In series, the optical fiber transmitter and optical fiber receiver are connected through multimode glass optical fiber cables, and the differential line driver is connected to PLC or computer.

[0015] In the rolling mill thickness aut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com