A kind of preparation method of the bamboo mat base material of composite plant fiber layer

The technology of a plant fiber layer and a production method is applied in the field of making a bamboo mat base material of a composite plant fiber layer, which can solve the problems of high production cost, unfavorable environmental protection, cumbersome process of bamboo silk base material, etc., and achieve the effect of saving production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

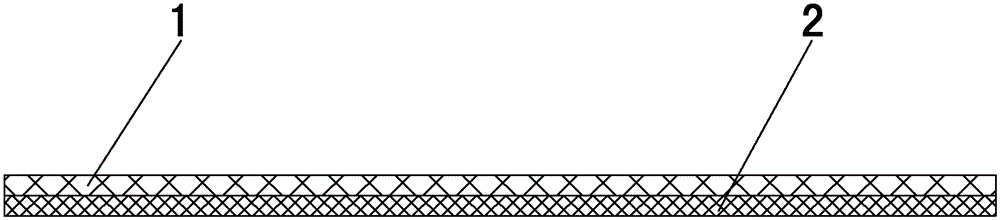

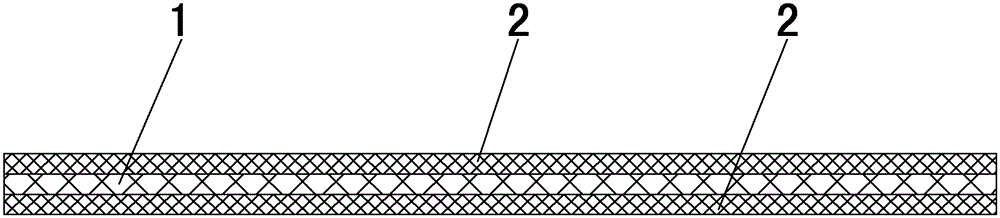

[0023] Such as figure 1 or figure 2 As shown, the present invention includes polished bamboo filaments 1, wherein the surface of the bamboo filaments 1 is provided with a plant fiber layer 2.

[0024] The plant fiber layer 2 is arranged on one or both surfaces of the bamboo filament 1 .

[0025] The plant fiber layer 2 is natural kraft paper.

[0026] The preparation method of the bamboo mat base material of described composite plant fiber layer, it may further comprise the steps:

[0027] Step 01: Washing and drying the polished bamboo thread 1 until the moisture content in the bamboo thread 1 is less than 15%;

[0028] Step 02: Strengthen and dye the plant fiber layer 2;

[0029] Step 03: apply adhesive on one side of the plant fiber layer 2;

[0030] Step 04: Put the bamboo filaments 1 into the fixture of the heat press and arrange them in rows;

[0031] Step 05: Attach the plant fiber layer 2 to one or both surfaces of the bamboo filament 1 and press it with a hot p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com